18

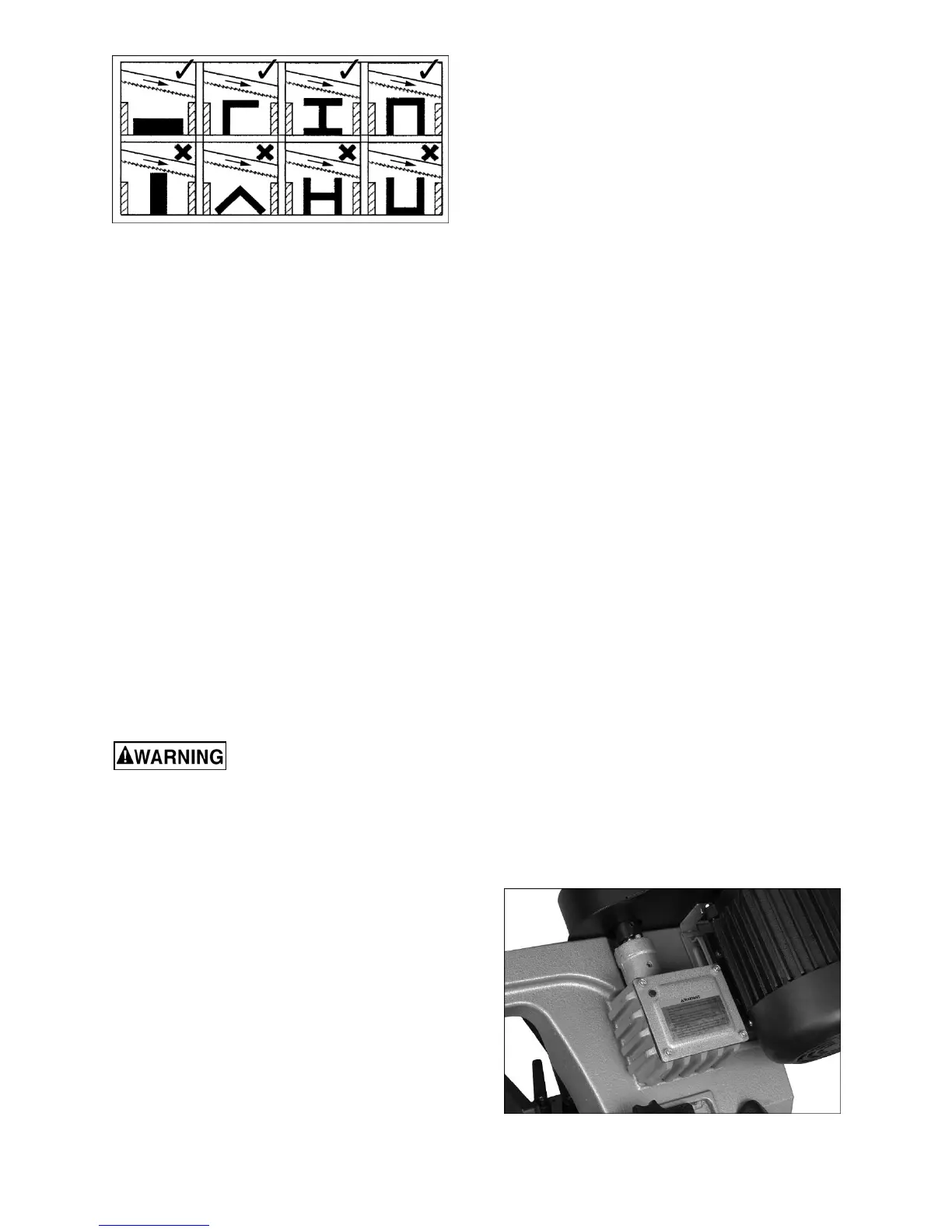

Figure 9-1: clamping positions

4. Adjust left blade guide to minimize exposed

blade area.

5. Set suitable feed rate on cylinder dial.

6. Open coolant valve, and open valve on

hydraulic cylinder to allow bow to descend in

gradual and controlled manner.

7. Switch trip tab must turn off saw at completion

of cut.

9.3 Evaluating cutting efficiency

Is the blade cutting efficiently? The best way to

determine this is to observe the chips formed by the

cutting blade.

If chip formation is powdery, then the feed rate is

much too light, or the blade is dull.

If chips formed are curled, but colored — that is,

either blue or straw-colored from heat generated

during the cut — then the feed rate is too high.

If chips are slightly curled and are not colored by

heat – the blade is sufficiently sharp and is cutting

at its most efficient rate.

10.0 User-maintenance

Always disconnect power to

machine before performing maintenance.

Failure to do this may result in serious personal

injury.

Keep all surfaces clean and free of rust, slag, chips,

and coolant build-up.

Clear metal particles with a small paint brush or

parts cleaning brush. Do not use compressed air, as

it may force chips into the guide bearings and other

critical areas of the saw.

Clean drain filter assembly.

Make frequent inspections of motor fan, and blow

out (with low pressure air hose) or vacuum any

accumulation of foreign material to maintain normal

motor ventilation.

Wipe saw down with a clean, dry cloth, and oil all

unpainted surfaces with light machine oil.

Keep blade guides clean and free of metal particles.

Check guide bearings frequently to make sure that

they are properly adjusted and turning freely.

Periodically inspect belt for wear or fraying. Replace

if needed.

To prevent corrosion of machined surfaces when a

soluble oil is used as coolant, pay particular

attention to wiping dry the surfaces where fluid

accumulates and does not evaporate quickly, such

as between machine bed and vise.

Place a thin coat of oil on bed surface on which vise

jaw slides.

If the power cord is worn, cut, or damaged in any

way, have it replaced immediately.

10.1 Lubrication

All ball bearings are permanently lubricated and

sealed. They require no further lubrication.

Lubricate the vise lead screw as needed with #2

tube grease.

Drain and refill gear box oil after first 90 days of

operation. Thereafter, change every six months.

Use 90W oil.

To change gear box oil:

1. Disconnect machine from power source.

2. Place bow in horizontal position.

3. Remove four screws from gear box and remove

cover plate and gasket. If more space is needed

to access gearbox, remove belt and adjust

motor away.

4. Hold a container under lower right corner of

gear box with one hand while slowly raising bow

with the other. Drain completely.

5. Return bow to horizontal position. Wipe out

remaining oil with a rag.

6. Replace gasket and cover. Fasten cover with

screws.

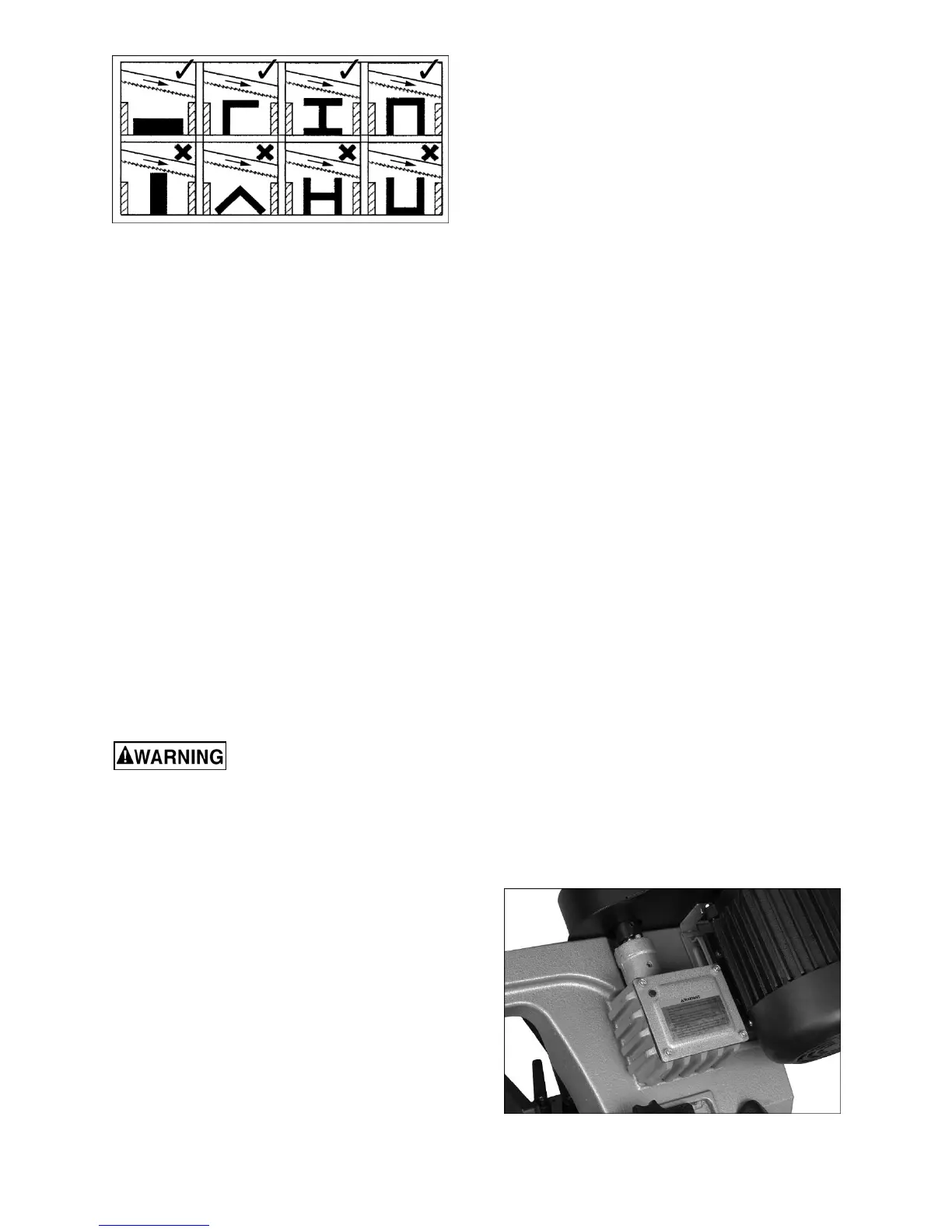

7. Remove vent plug (Figure 10-1) with 8mm

wrench, and fill gear box with approximately 1/2

pint of 90W oil, through the hole. Reinstall vent

plug.

Figure 10-1: gearbox

Loading...

Loading...