REMOVING

SAW

BLADE

When

removing saw blades from your saw, make sure the saw is disconnected from. the power

source. Remove the table insert, place a

block

of wood

against

the front of the

saw

blade

and

and using the arbor nut wrench, turn the arbor nut toward you.

OPERATION

Plain

sawing includes ripping

and

cross

cutting,

plus

a few other standard operaHons

of

a

fundamental nature. The

following

methods feature

safety.

As

with

ali

power tools

there

is a

certain amount of hazard invloved

with

the operator and his use of the tool. Using the tool

with

the respect and caution demanded as far as

safety

precautions are concerned wi Il

considerably

!essen the

possibility

of persona!

injury.

However,

if

normal

safety

precautions are overlooked

or completely ignored, persona!

injury

to the operator can develop.

1t

is

good practice

to

make

trial cuts using scrap material

when

setting

up

your saw

for

operation.

CROSS

CUTTING

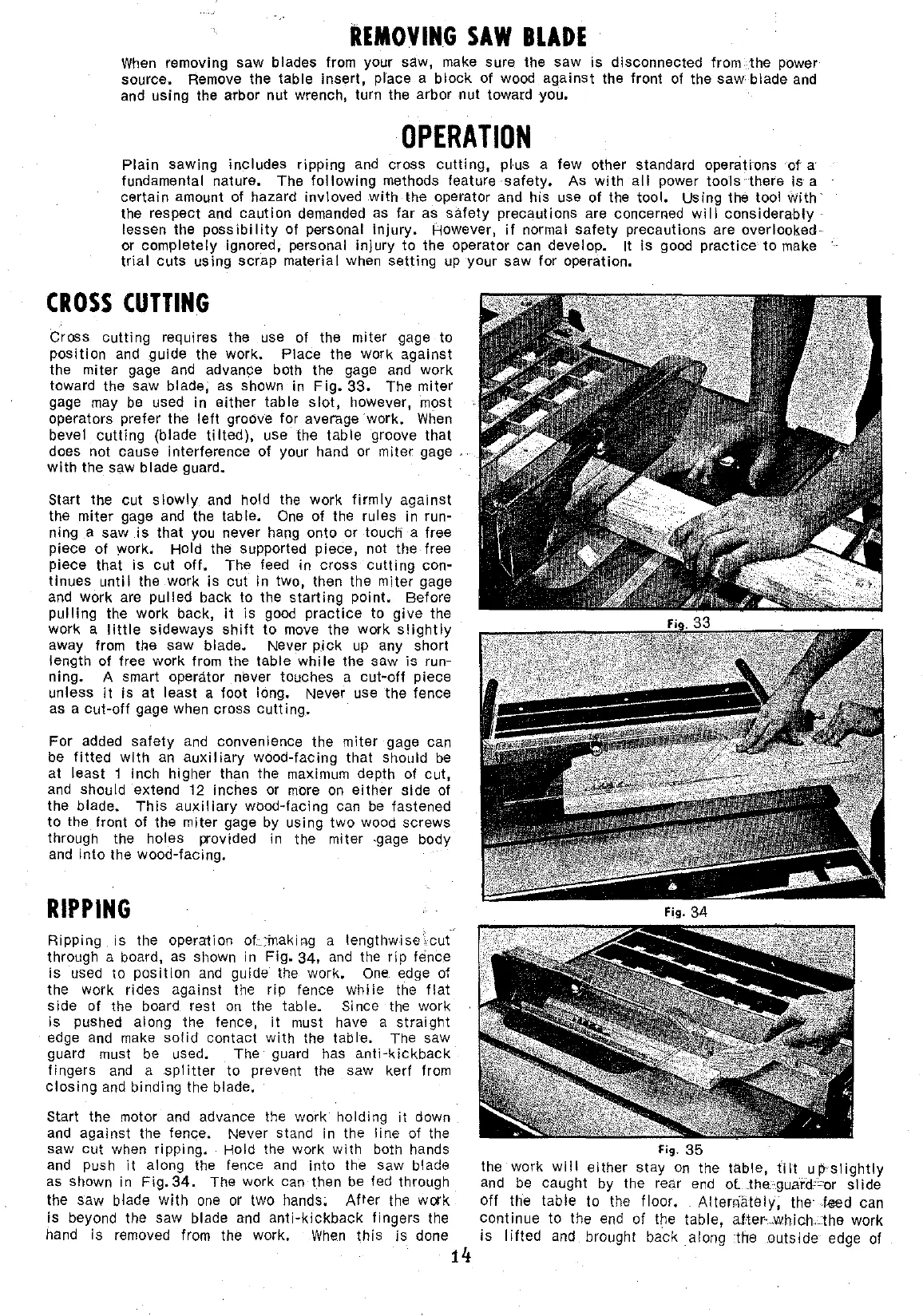

Cross

cutting

requires the use of the miter gage to

position

and guide the work. Place the work against

the miter gage

and

advance bath the gage

and

work

toward the saw blade, as shown in

Fig.

33.

The miter

gage may

be

used in

either

table

slot,

however, most

operators prefer the

left

groove for average work.

When

bevel

cutting

(bi ade ti lted), use the

table

groove that

does not cause interference of your hand or

miter

gage ..

with

the saw bi

ade

guard.

Start the eut

slowly

and

hold the work

firmly

against

the miter gage

and

the table.

One

of the rules in run-

ning a saw

is

that you never hang onto

or

touch a free

piece of work. Hold

thé supported piece, not the free

piece

thal

is eut

off.

The feed in cross

cutting

con-

tinues

unti 1 the work is eut in two, then the miter gage

and

work are pulled back to the

starting

point. Before

pulling

the work back,

it

is

good

practice

to

give

the

work a

little

sideways

shift

to

move the work

slightly

away from the saw blade. Never

pick

up

any short

length of free work from the table

while

the saw is run-

ning. A smart operàtor never touches a eut-off piece

unless

it

is at least a foot long. Never use the tence

as a

cut·off

gage when cross

cutting.

For added

safety

and

convenience the miter gage can

be

fitted

with

an

auxiliary

wood-facing

thal

should

be

at least 1 inch higher than the maximum depth of eut,

and

should extend 12 inches or

more

on

either

side of

the blade.

This

auxiliary

wood·facing can

be

fastened

to

the front of the miter gage by using two wood screws

through the hales provided in the miter .gage body

and

into the wood·facing.

RIPPING

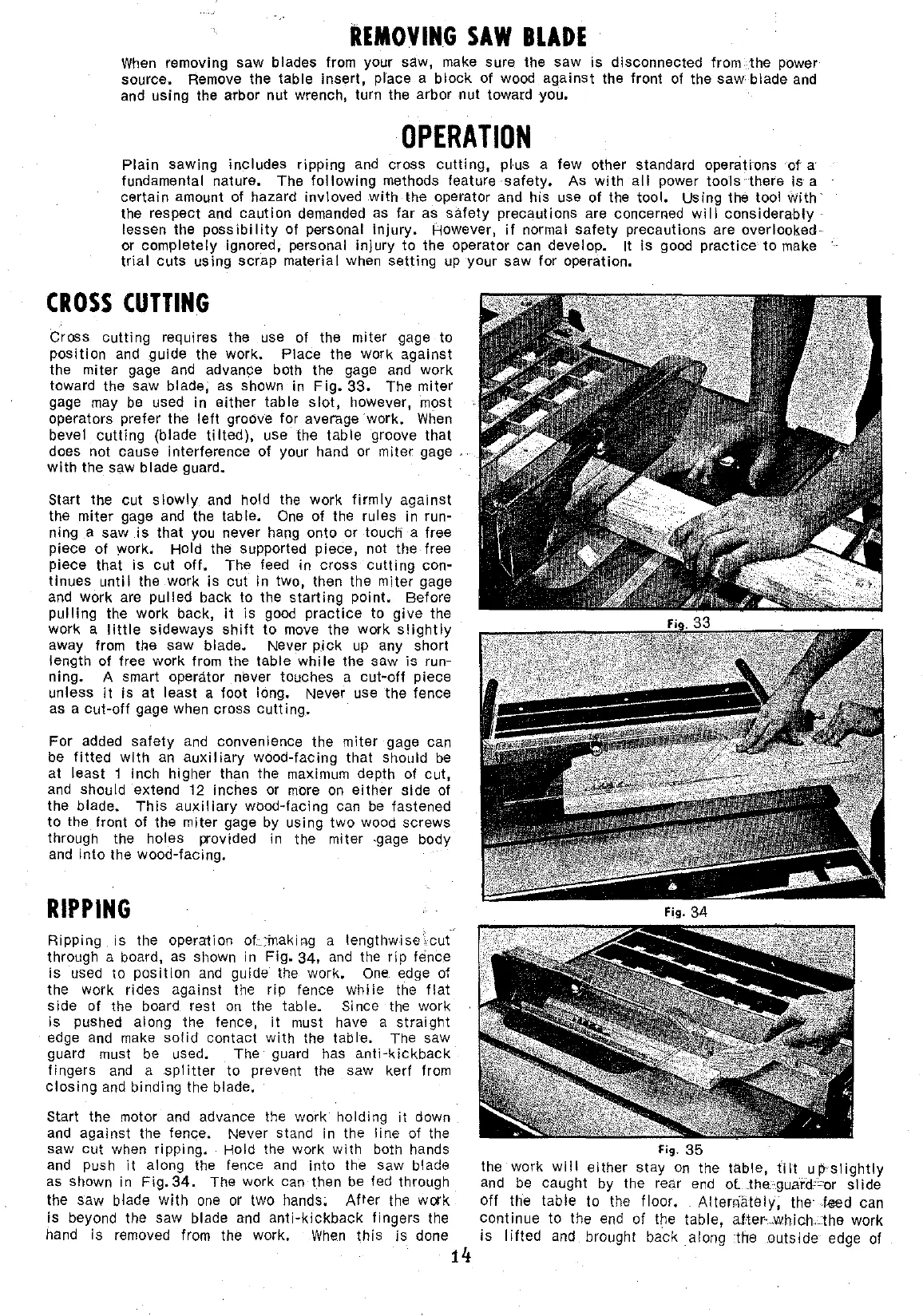

Ripping is the operalion oL:fnakil'lg a

lengthwisekut

through a board,

as

shown in

Fig.

34,

and

the

rip

fénce

is

used to

position

and

guide

the work.

One

edge of

the work rides against the

rip

tence whi le the

flat

side of the board rest

on

the table. Since the work

is pushed along the tence.

it

must have a

straight

edge

and

make

solid

contact with the table. The saw

guard must

be

used. The guard has

anti·kickback

fingers

and

a

splitter

to

prevent the saw kerf from

closing

and

binding the blade.

Start the motor

and

advance the work holding

it

dawn

and against the tence. Never stand in the

line

of the

saw eut when ripping. Hold the work

with

bath hands

and

push

it

along the tence

and

into

the saw blade

as shawn in

Fig.34.

The work can then

be

led through

the saw blade

with

one

or

two hands.

Alter

the work

is beyond the saw blade

and

anti·kickback

fingers the

hand is removed from the work.

When

this

is done

14

Fig.

35

the work

will

either stay

on

the table, t'ilt

up·slightly

and

be

caught by the rear

end

ot

Jhe·guaido=or si ide

off

the

table

to the

floor.

Alter~alely,

the·

f<Jed

can

continue to the

end

of the table,

aHer·which

the

work

is

lifted

and

brought back

along

·the .outside edge of

Loading...

Loading...