RIP

FENCE

OPERATION

AND

ADJUSTMENTS

The

ri·p

fence can

be

used

on

eitlier side

of

the saw

blade. The most

common

location

is

on

the right hand

side. The

rip

tence is guided by means of guide

rails

fastened to the front '\nd rear

of

the table. The front

guide rai

1

is

calibrated ta show the distance the tence

is set from the .saw blade.

Ta

"move

the

rip

tence, rai

se

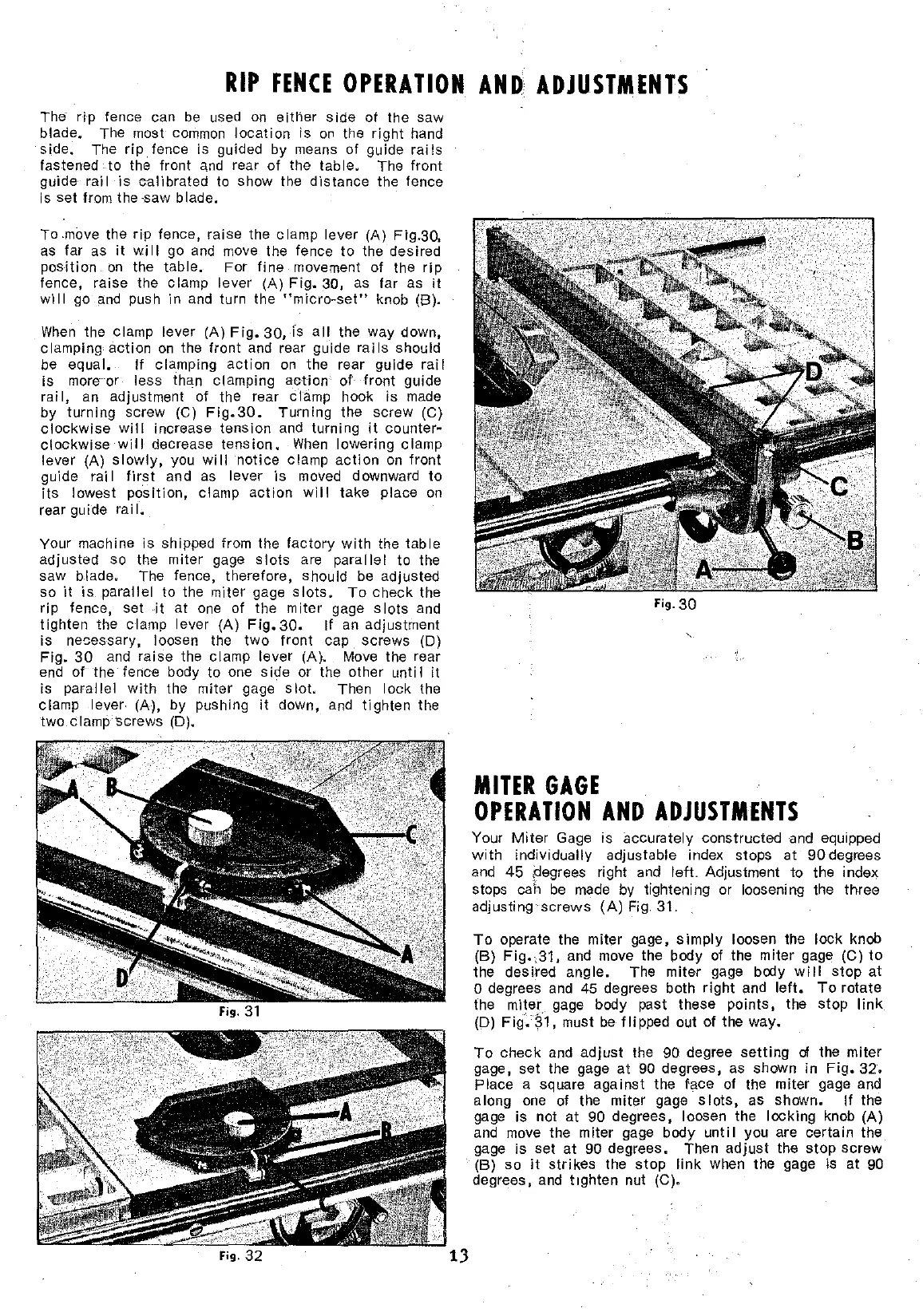

the clamp lever (A) Fig.30,

as

far as

it

wi Il go

and

move

the tence

ta

the desired

position

on

the table. For fine movement of the

rip

tence, raise the clamp lever (A)

Fig.

30, as far as

il

will

go

and

push in

and

turn the

"micro-set"

knob (B).

When

the clamp lever (A)

Fig.

30,

fs

ali

the way dawn,

clamping action

on

the front

and

rear guide

rails

should

be

equal. If clamping action

on

the rear guide

rail

is more or less !han clamping

action

of

front guide

rai

1,

an adjustment

of

the rear Clàmp hook is made

by turnlng screw (C)

Fig.30.

Turning the screw (C)

clockwise will increase tension

and

turning

it

counter~

clockwise

will

decrease tension.

When

lowering clamp

lever (A)

slowly,

you

will

notice clamp

action

on

front

guide rai

1

first

and as lever

is

moved downward

ta

its

lowest position, clamp

action

will

take place

on

rear guide rai

1.

Yaur machine

is

shipped from the factory

with

the

table

adjusted so the miter gage

slots

are

parallel

to the

saw blade. The tence, therefore, should

be

adjusted

sa

it

is

parai lei

ta

the miter gage

slots.

To

check the

rip

tence, set

it

at

one

of the miter gage

slots

and

tighten the clamp lever (A)

Fig.

30.

If

an

adjustment

is nesessary, loosen the

two

front

cap.

screws (D)

Fig.

30

and

raise the clamp lever (A).

Move

the rear

end

of the· tence body ta one s ide or the other

un

ti 1

it

is parallel

with

the miter gage

slot.

Then lock the

clamp lever (A), by pushing

il

dawn,

and

tighten the

two

clamp screws (D).

MITER

GAGE

OPERATION

AND

ADJUSTMENTS

Your

Miter

Gage

is

accurately constructed

and

equipped

with

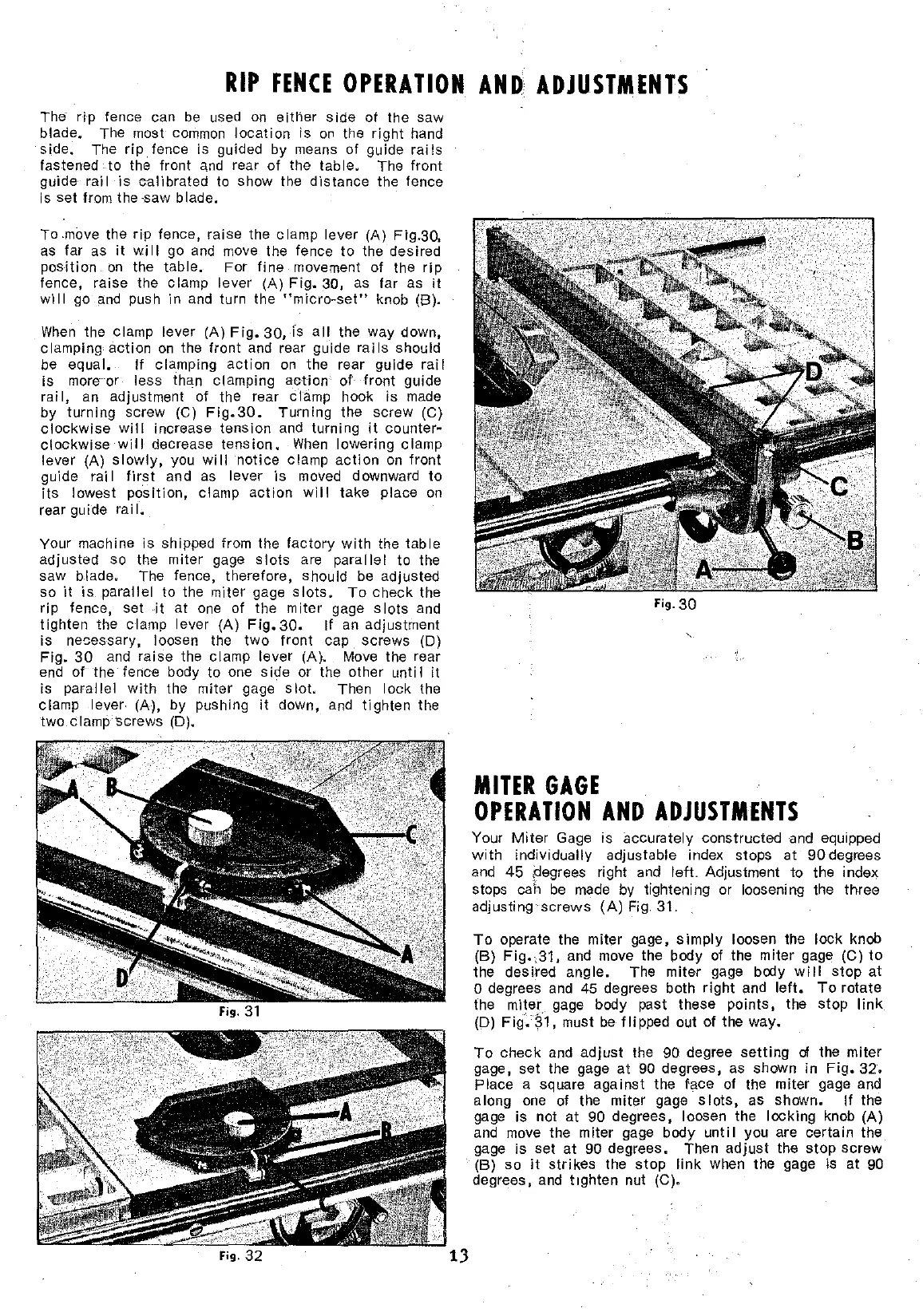

individually adjustable index stops at

90

degrees

and

45

t]egrees righi

and

lefL

Adjustment ta the index

stops cah

be

made

by

tightening or loosening the three

adj

us

ting

screws

(A)

Fig"

31"

Ta

operate the miter gage,

simply

loosen the lock knob

(B)

Fig.,31.

and move the body of the miter gage (C)

ta

the desired angle. The miter gage body

will

stop

at

o degrees

and

45

degrees bath

right

and

left.

Ta

rotate

the miter gage body past these points, the stop

link

(D)

Fig.~1,

must

be

flipped

out of the way.

Ta

check

and

adjust

the 90 degree

setting

d the miter

gage, set the gage

at

90

degrees, as shawn in

Fig.

32.

Place a square

against

the

lace

of the miter gage

and

along

one

of the miter gage

slots,

as shawn.

If

the

gage is not at 90 degrees, loosen the locking knob (A)

and

move the miter gage body

until

you are certain the

gage is set at

90 degrees. Then

adjust

the

stop

screw

(B) sa

it

strikes

the

stop

link

when the gage is at

90

degrees, and t1ghten nul (C).

Loading...

Loading...