Figure 18

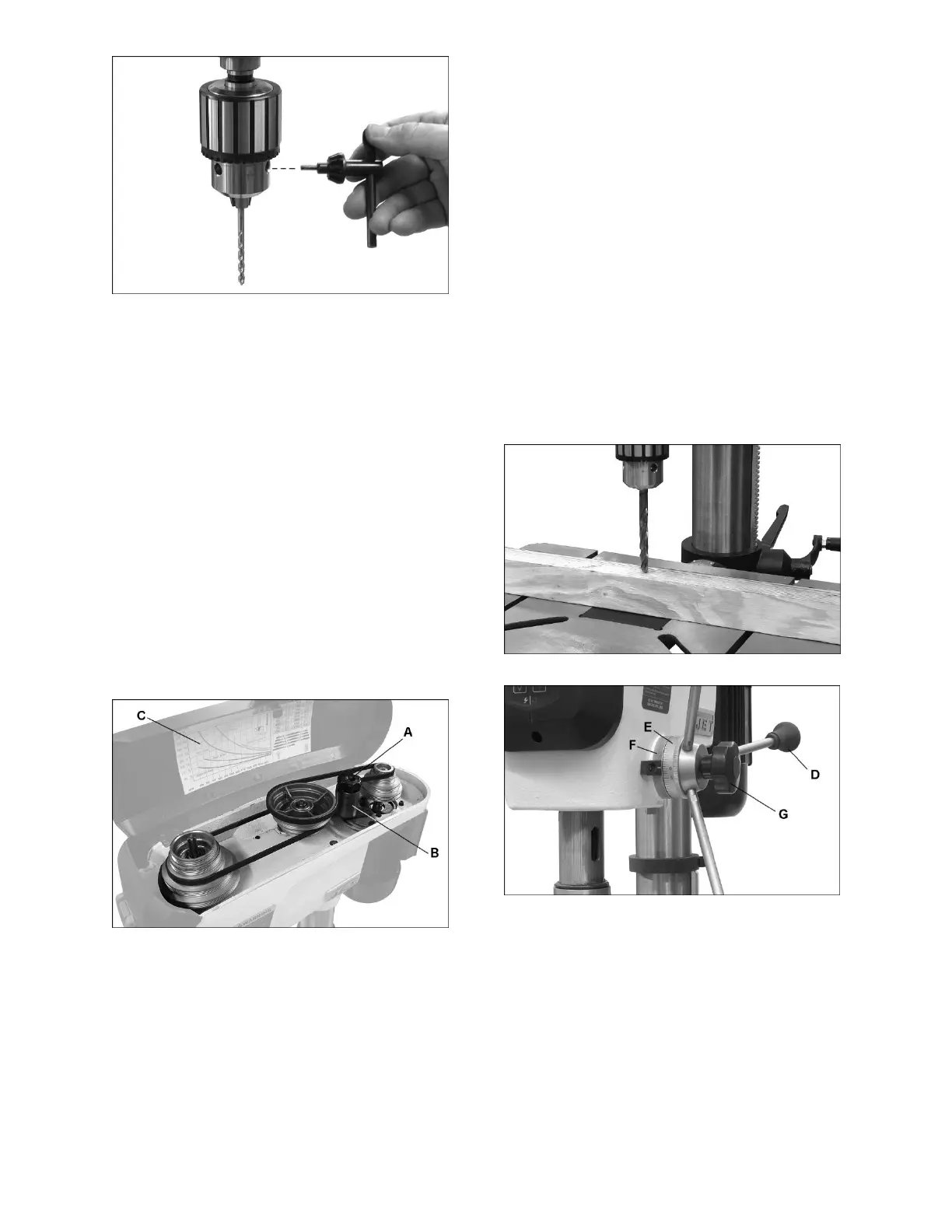

8.7 Changing spindle speeds

Refer to Figure 19.

1.

Disconnect machine from power source

.

2.

Open belt cover. Loosen knob (A, Figure 19)

and pull tensioner (B) away from belt to releas

e

tens

ion.

3.

Consult speed chart (C) and position belts

accordingly.

Note: The center pulley can be pushed to front

or back to release tension to either belt, as

needed. When front belt is correctly positioned,

push center pulley backward to tighten front belt

and allow rear belt to slide onto the pulleys

.

4.

Make sure belts are properly seated in the

grooves of each pulley.

5.

Push tensioner (B) into belt and tighten knob

(A). Clos

e hood.

Figure 19

8.8 Depth stop

The depth stop is used for repetitive drilling of holes

of identical depth.

Depth stop can be established by one of two

procedures:

Method #1:

Refer to Figures 20 and 21.

1.

Loosen lock handle (G, Figur

e 21).

2.

Use downfeed handles (D, Figure 21) to lower

the bit until it just contacts the top surface of

workpiece, as shown

in Figure 20.

3.

Hold downfeed handle in position, and rotate

scale ring (E, Figure 21) to zero. This sets

the

work

piece surface as your zero referenc

e point.

4.

Move workpiece out from un

der bit, and rotate

downf

eed handle to lower bit until sca

le ring (E)

reads

your desired depth.

5.

Hold downfeed handle in this position, and

rotate lock ring (F) counterclockwise as far as

it

will tur

n. You should be able to feel and hear

when the lock ring reaches the end of its

rotation.

6.

Tighten lock handle (G

).

7.

The bit can now be repeatedly

lowered to the

pre-s

et depth using the downfeed handles.

8.

To release the depth stop, loosen lock handle

(G).

Figure 20

Figure 21

M

ethod #2:

Refer to Figures 22 and 23.

1.

Mark the desired depth of cut on the side of the

workpiece (Figure 22).

2.

Use downfeed handle (D, Fi

gure 23) to lower

the bit to the

mark. Hold downfeed handle in

position.

3.

Rotate lock ring (F) counterclockwise as far as

it will turn. You should be able to feel and

hear

when the loc

k ring reaches the end of its

rotation.

Loading...

Loading...