Exposed metal surfaces of table and base should be

kept clean and free of rust. Protective sprays or

paste wax are available from most hardware stores.

Note: Avoid wax that contains silicone or other

synthetic ingredients; these materials can find their

way into lumber and make staining and finishing

difficult.

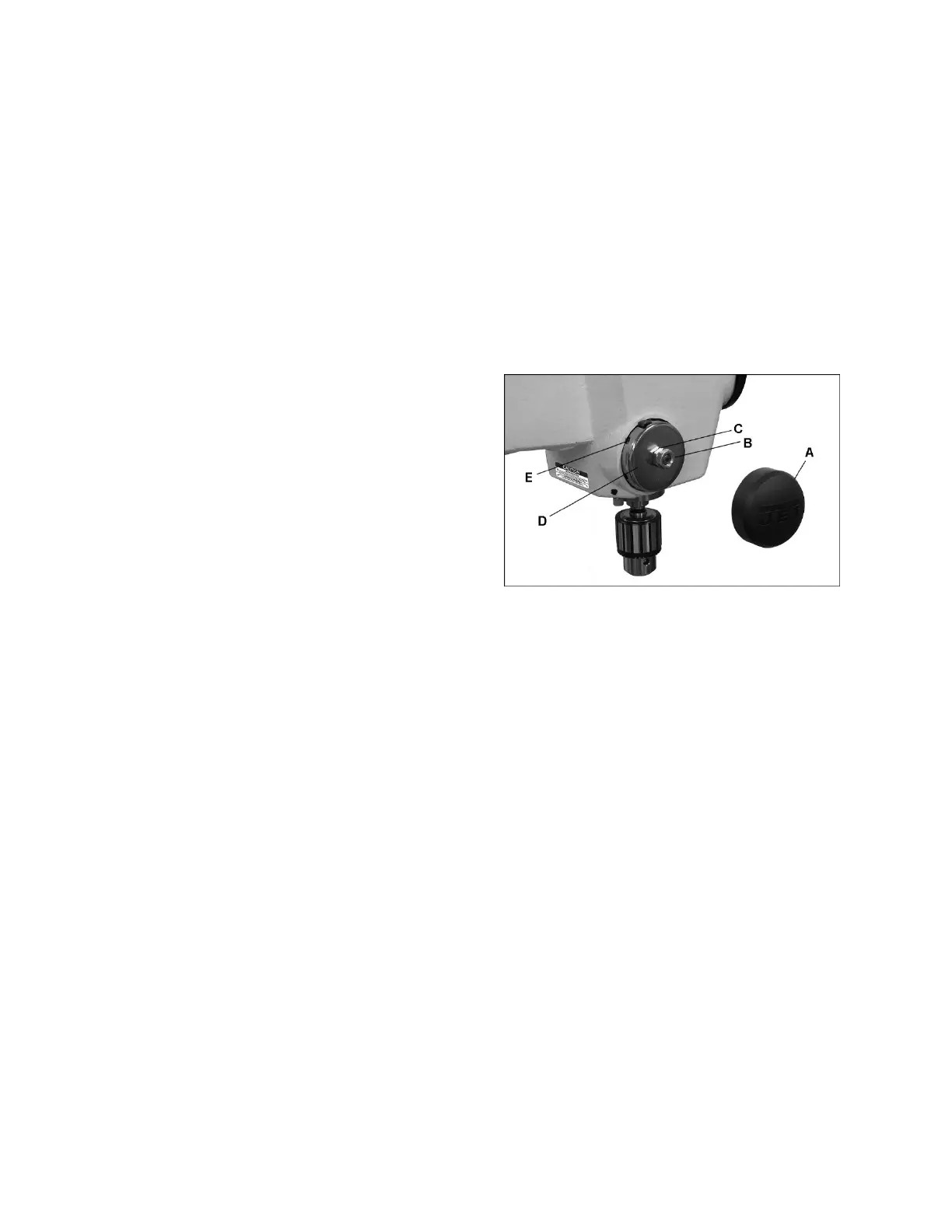

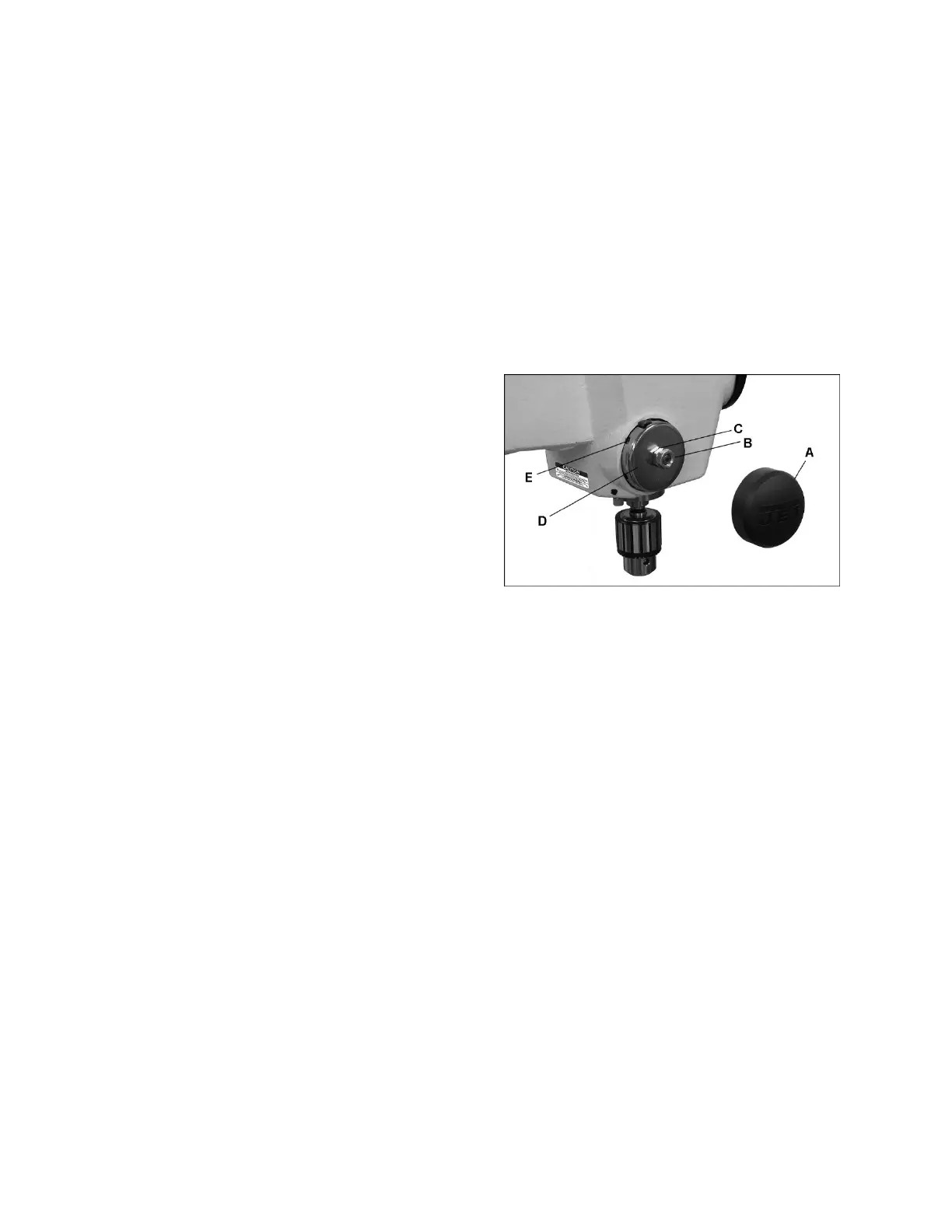

The quill return spring should receive SAE 20 oil

once yearly. Apply the oil beneath the spring

housing (D, Figure 31) using a squirt can.

If the drill press is not to be used for an extended

period, loosen the tensioner (B, Figure 19) to reduce

stress on the belts.

11.1 Belt replacement

To loosen and remove the existing poly-v belts, use

the same procedures described in sect. 8.7,

Changing spindle speeds.

11.2 Return spring

The tension of the return spring, which raises the

spindle after drilling, has been pre-set by the

manufacturer. No further adjustment should be

attempted unless absolutely necessary. Should

spindle retraction weaken after long-term use of the

drill press, tighten the spring tension as follows.

1.

Disconnect machine from power source

.

2.

Pull off c

ap (A, Figure 31).

3.

Loosen jam nut (B), and loosen inner nut (C) a

small amount. Do not remove the hex nuts. The

nuts should be backed off just

enough to allow

the s

pring housing (D) to be disengaged from

the pin on the head casting.

4.

Slightly pull out the spring hous

ing (D) while

f

irmly holding it. DO NOT allow the sp

ring

hous

ing to turn freely in your hand, or the spring

will unwind.

5.

Rotate spring housing until tab (E) on the spring

retainer engages the next notch in spring

housing. Rotate coil spring hous

ing

c

ounterclockwise to increase spring tension,

clockwise to decreas

e.

6.

Push spring housing back in. Make sure it has

re-engaged with the pin before releasing your

grip on the housing.

7.

Tighten inner nut (C) until it makes very

light

c

ontact with the spring housing. Do not

overtighten the inner nut, as it may caus

e

binding o

f the pinion shaft.

8.

Hold the inner nut with a wrench to prev

ent

f

urther movement, while tightening the jam nu

t

(B) against the inner nut.

9. Ins

tall cap

(A).

Figure 31

11.3 Additional servicing

Any other servicing of the drill press should be

performed by an authorized service representative.

Loading...

Loading...