21

10.2 Periodic maintenance requirements

During operation, periodically vacuum and brush chips

and debris from machine.

Operate knee and table lead screws through full range

of movement to evenly distribute lubricant.

Apply light machine oil to work table and other exposed

metal surfaces to prevent rust or corrosion.

Remove vent panels to check pulleys and belts for

unusual wear or grooving. NOTE: Operators should vary

speed occasionally to prevent formation of grooves on

pulley surfaces.

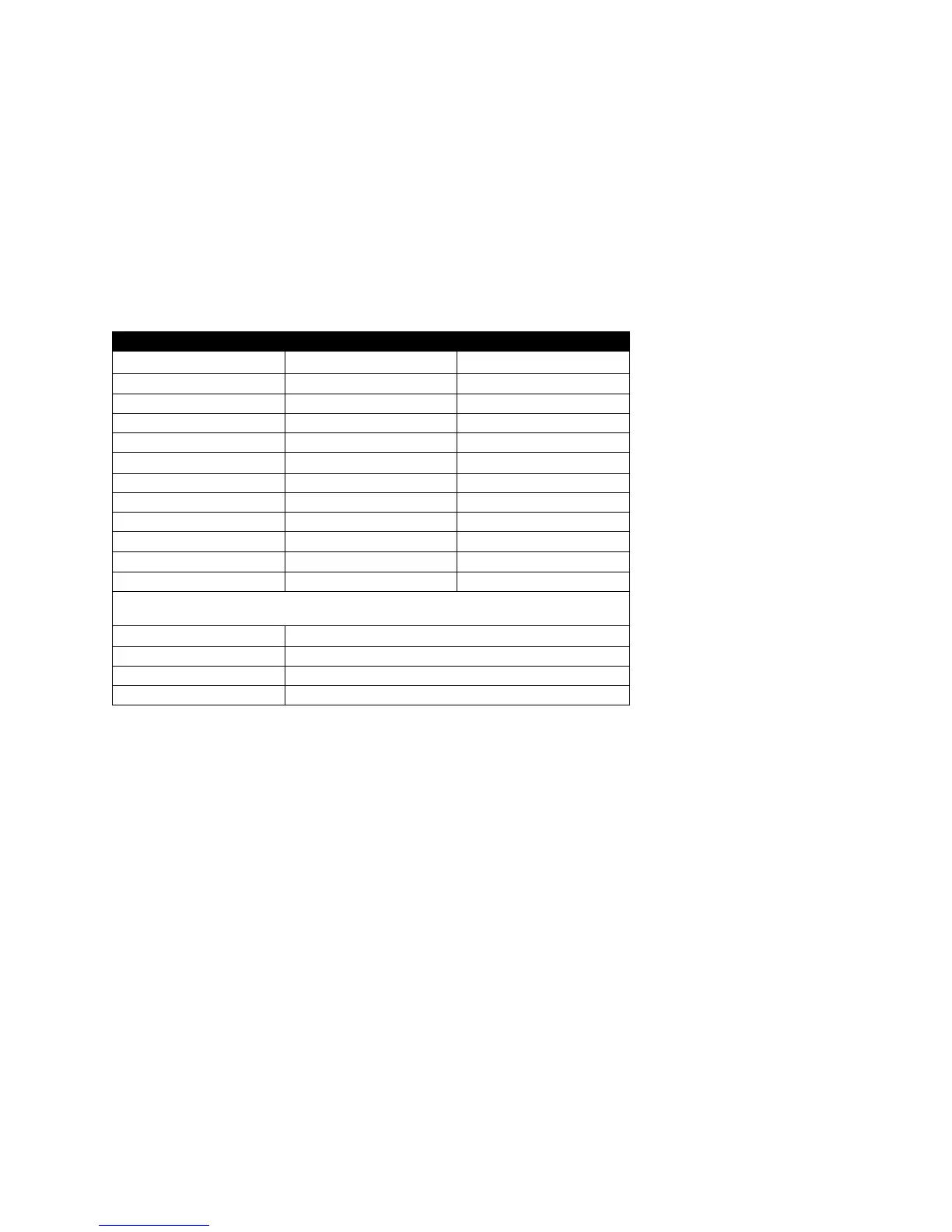

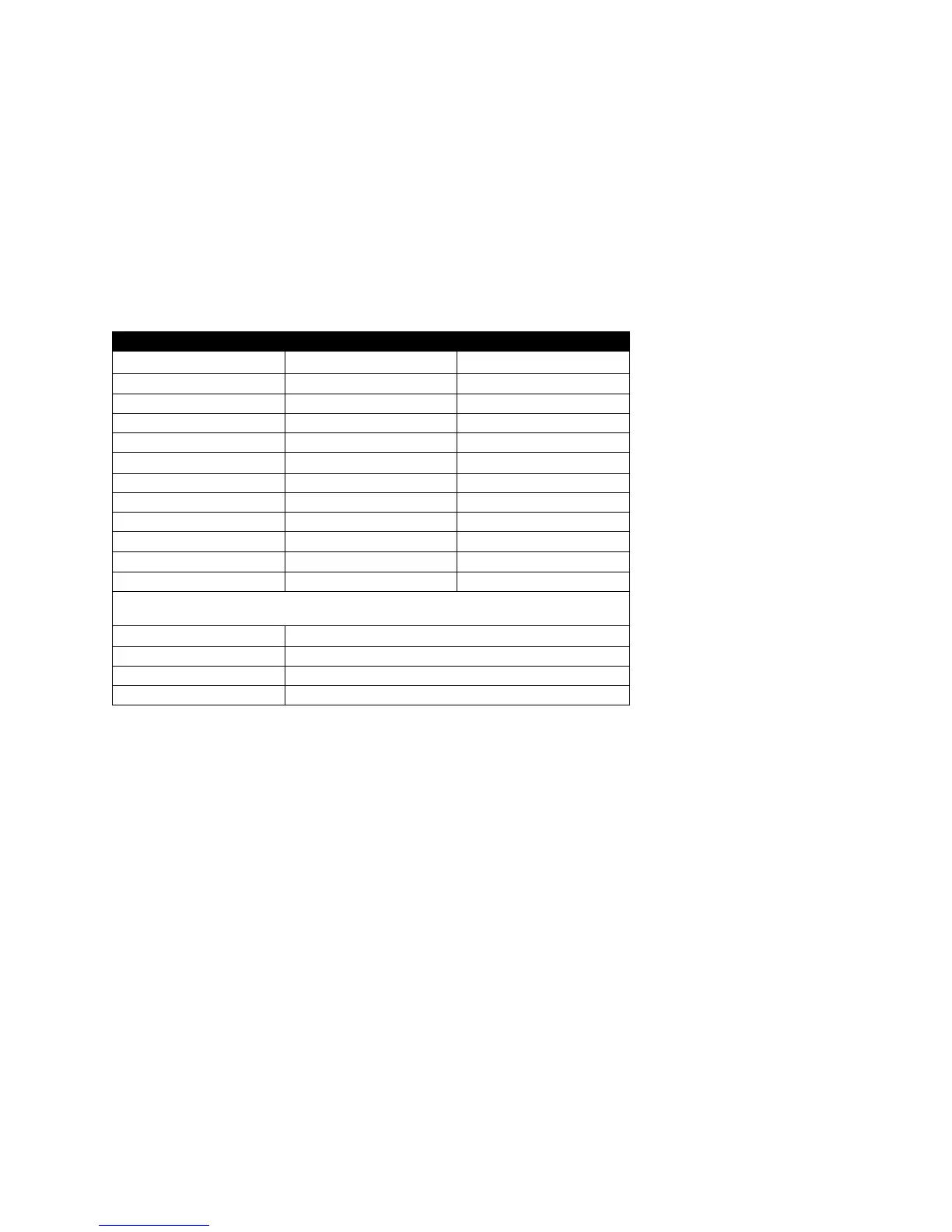

11.0 Recommended speed for mill and drill operations

Mill cutting speed recommended (mm/min)

V=

πDN/1000

cutting speed (mm

min)

Material Heavy cutting Processing cutting

Cast iron 30-40 45-90

Malleable iron 37-45 45-90

Steel (soft) 60-90 75-105

Steel (medium) 454-67 52-75

Steel (hard) 24-37 55-75

Cast steel 24-30 55-75

Aluminum 240-300 300-360

Brass 105-180 150-300

Bronze 52-75 75-90

Magnesium alloy 240-300 300-600

Zinc alloy 120-240 210-450

Drill speed (RPM) recommended

5mm hole 1000-1500

10mm hole 500-800

13mm 300-500

20mm 150-300

Table 5

12.0 Replacement parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1-800-

274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Having the Model Number and Serial Number of

your machine available when you call will allow us to serve you quickly and accurately.

Non-proprietary parts, such as fasteners, can be found at local hardware stores, or may be ordered from JET.

Some parts are shown for reference only, and may not be available individually.

Loading...

Loading...