Bareshaft Pump

7

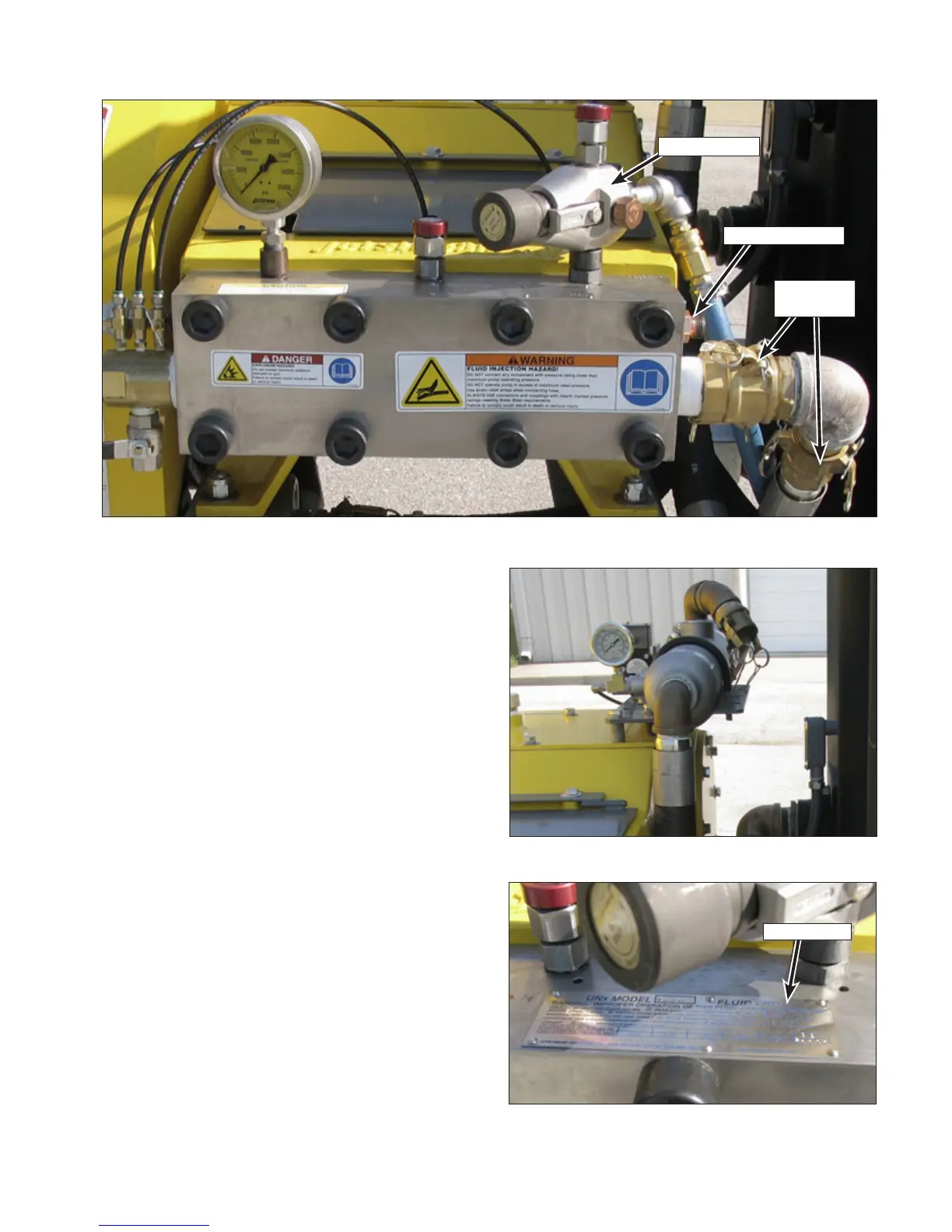

Supply Couplings

The supply couplings provide a quick method for

attaching the supply hose to the manifold.

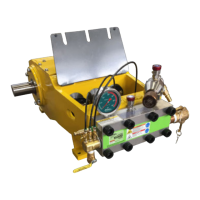

Secondary Filter (40K Units)

A secondary lter (Figure 4) is mounted on top of the

pump for use when operating at “40K”. The lter is

not connected during 15K or 20K operation.

A pressure gauge is mounted on the lter to monitor

pressure in the lter.

A differential pressure switch is mounted in the lter

circuit to monitor proper ow through the lter. If the

lter becomes plugged and ow is insufcient, the

switch will cause the engine to shut off. “Emergency

Stop” will be displayed on the control panel.

A drain valve is located on the lter cover that allows

the operator to purge air from the lter at startup.

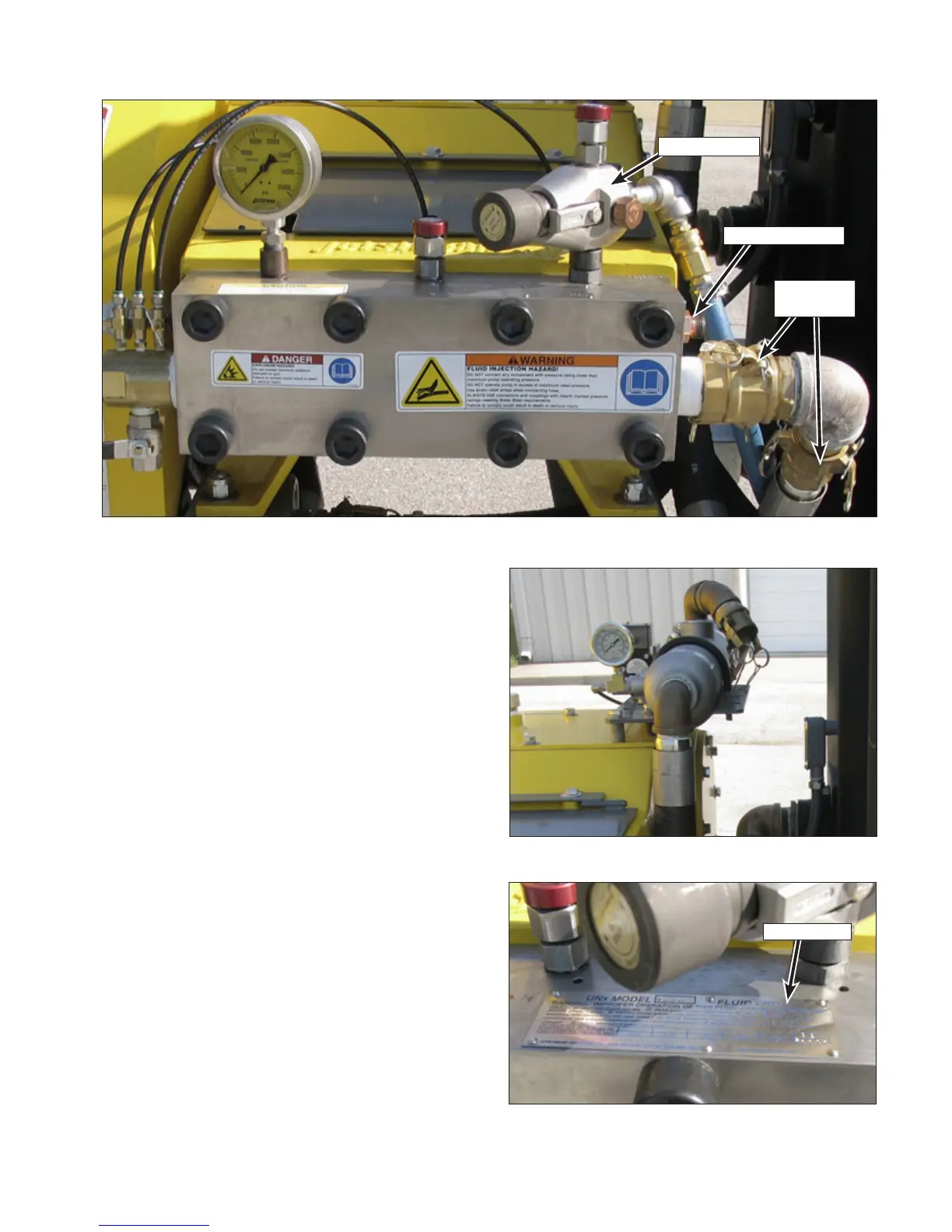

Fluid End Identication

A plate (Figure 5) is attached to all uid end mani-

folds. The plate is stamped with the uid end model

number. In addition, the plate is stamped with plung-

er size and output pressure related to that plunger

size. Refer to this plate before operating the pump.

Discharge Fitting

Supply

Couplings

Bypass Valve

Figure 3: Pump Components (Continued).

Figure 4: Secondary Filter.

Rating Plate

Figure 5: Fluid End Rating Plate.

Loading...

Loading...