Bareshaft Pump

9

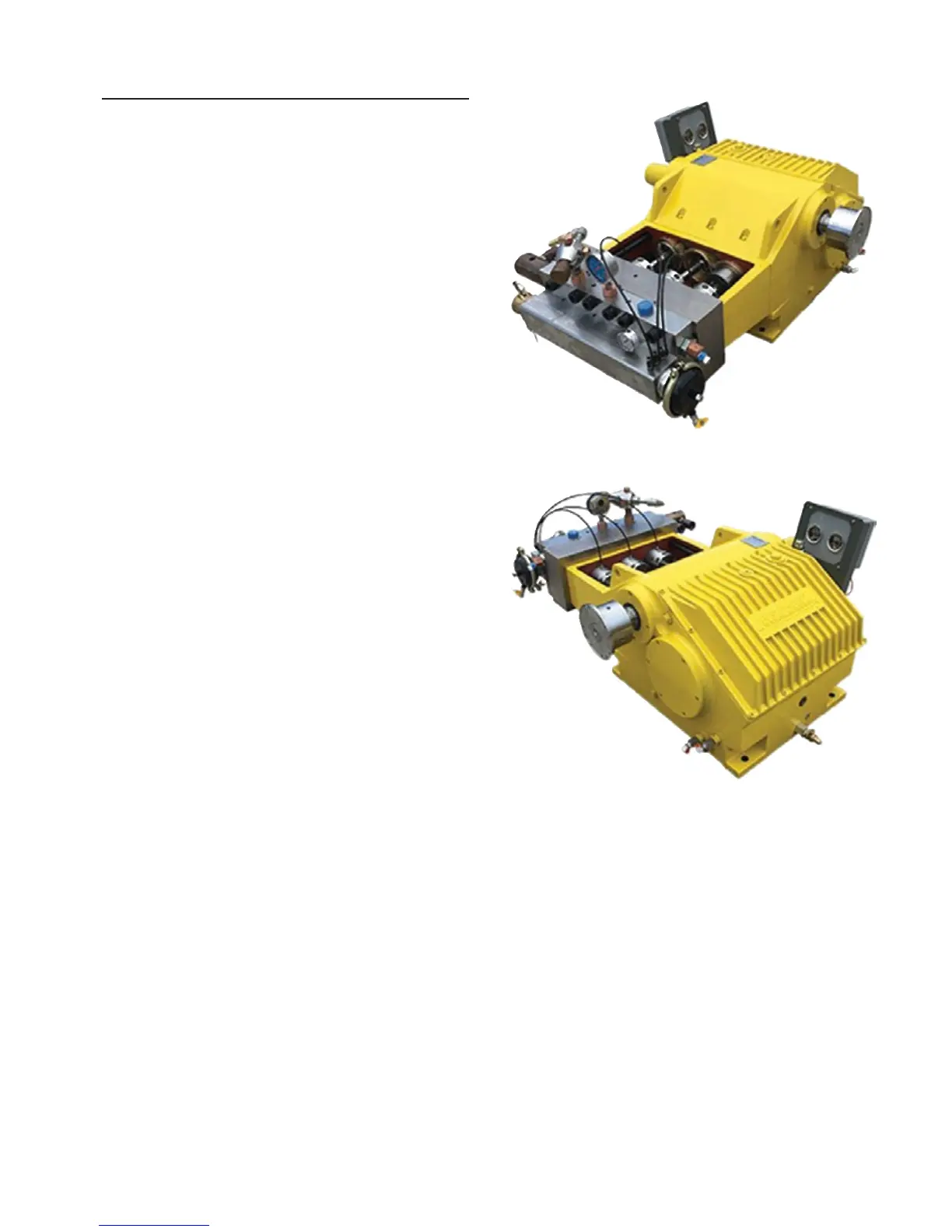

Jetstream 6000

Bareshaft Pump Installation

Guidelines

All of the previous requirements are the same for

6000 except as noted below:

The 6000 powerend is internally geared and requires

inline drive with flexible coupling ***. It is available in

four different gear ratios to support diesel engine or

electric motor input speeds. It can be supplied left or

right hand drive but must be driven with input shaft

rotating top towards rear (i.e. LH requires CCW and

RH requires CW at input shaft).

6000 series 600 hp max 457 rpm max

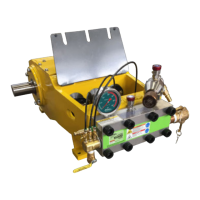

Water Supply

The 6000 pump cannot be gravity fed and requires

40-50 psi suction water pressure at full pump speed

to operate. As such it is supplied with lube water flow

control valves mounted on the suction manifold. All

fluid ends have a maximum inlet supply pressure of

75 psi.****

Lubrication

The powerend is lubricated with 12 gallons of ISO

320 gear oil. Only the following brands are allowed:

• Aral Motanol HP 320

• Mobil DTE. Oil AA 320

• BP Energol CS 320

• Shell Vitrea 320

• Castrol Alpha ZN 320

• Valvoline IRF 320

• Dea Oursa OEL P 320

• Elf Polytelis 320

• Esso Nuto 320

The 6000 powerend is equipped with an oil tempera-

ture shutdown gauge and the maximum allowed oil

temperature is 190°F (normal range is 160-170°F).

An integrated oil cooler (dual loop) is located inside

the powerend sump and uses 3-5 gpm (15-20 lpm)

of suction water to cool the oil. The warm water

outlet of this cooler will need to be plumbed back

into the cold water supply tank or routed to an appro-

priate drain. The oil is pumped via external oil pump

through external filter and routed inside powerend to

critical points. It is supplied with an oil pressure shut-

down gauge and requires 30 psi minimum (normal

operating range is 60-70 psi). The filter should be

changed every 500 hours.

Loading...

Loading...