Bareshaft Pump

21

WATER

Water Quality Requirements

The quality of water that is supplied to your Jet-

stream pump can have a direct impact on perfor-

mance. Items like dissolved solids and pH values out

of the allowable range can, either by themselves, or

together with other properties of the water, lead to

premature failure (such as cracking) of pump com-

ponents and related accessories.

Suspended gasses (tiny bubbles) in the water can

also lead to premature component failure. These

gases can sometimes be detected visually by in-

specting the water in the inlet tank for tiny bubbles or

a milky appearance.

As part of the installation and or operating proce-

dures of this pump, an expert that specializes in

water quality must perform a water quality test. If

your water is found to exceed any of the allowable

measurements in the chart below, consult a special-

ist in water purication and conditioning.

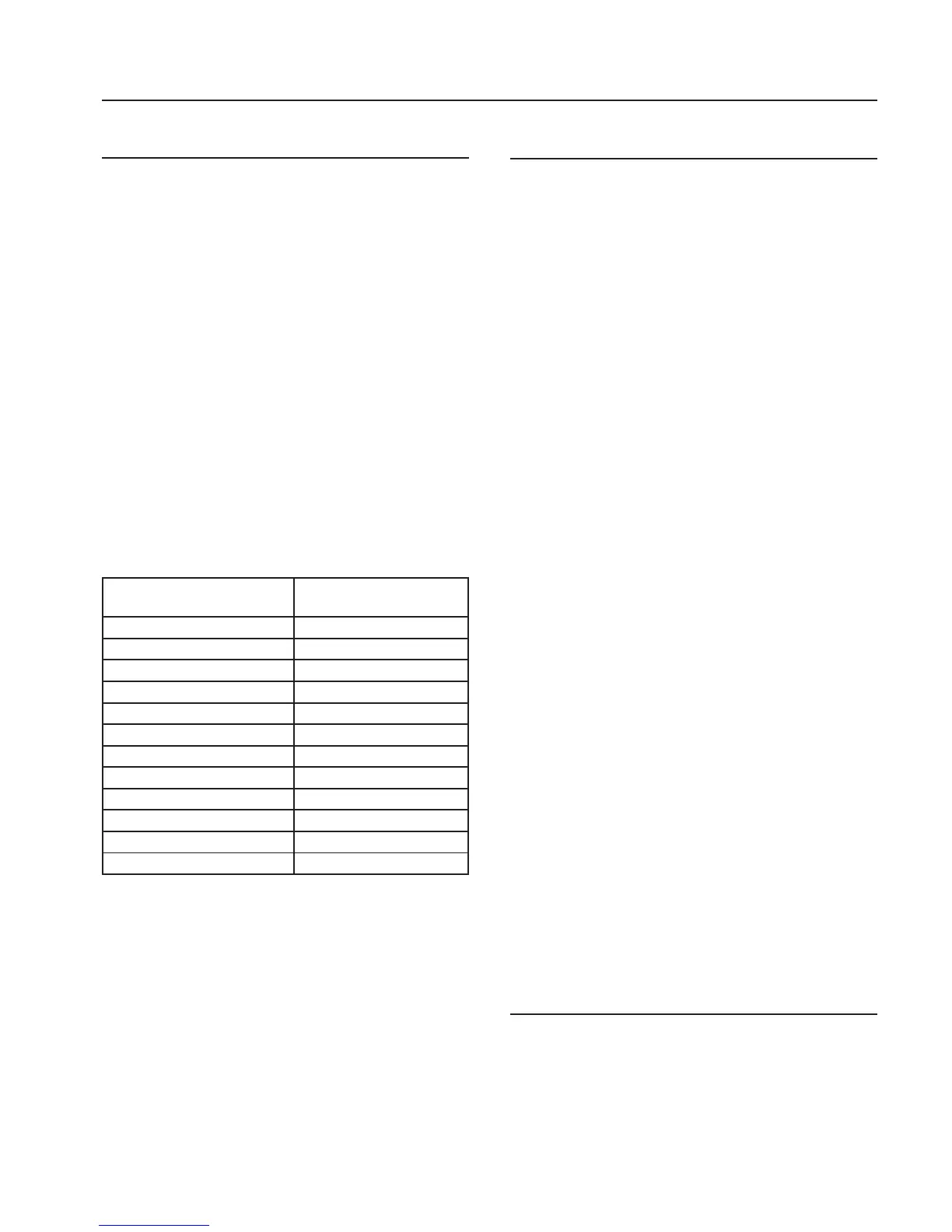

Recommended water quality levels:

Substance

Maximum Allowed

(mg/L)

Silica 1.0

Calcium 0.5

Magnesium 0.5

Iron 0.1

Manganese 0.1

Chloride 5.0

Sulfate 25.0

Nitrate 25.0

Carbon Dioxide 0

Total Dissolved Solids 50.0

pH 6.8 – 7.5

Specic Conductivity 50 micro-mhos/cm

Note: Boiler water additives with either

ammonia or amines are not allowed.

Note: If water that has been treated by either

reverse osmosis or deionization is to

be used in your pump, it is important

that it does not have a total dissolved

solids (TDS) reading of less than 0.5

ppm. Water with a TDS reading of 0.5

ppm or less has been known to attack

carbide components such as plungers

and back-up rings.

Fluid Compatibility with

Jetstream Pumps

Jetstream pumps are designed and built primari-

ly for pumping water at various pressure ratings.

Jetstream does not have a compatible fluids list at

this time. The use of any fluids other than water void

warranty.

There are special considerations for seawater ap-

plications. Please consult the factory for a specic

application.

There are instances where fluids besides water to be

pumped are considered for use in Jetstream pumps.

Jetstream does not approve the suitability of their

pumps for use with any other fluid besides water, for

the following primary reasons:

• Safety and Environmental: Water leakages in

the high pressure system, pump, waste water,

bypass water, etc., are normally quite easily con-

tained (if necessary) and/or produce zero-risk to

low-risk situations.

• Corrosion Resistant Pump Components: The

stainless steel components in the fluid handling

portion of the Jetstream pump offer good corro-

sion resistance to water.

• Operational Characteristics: The plunger seal-

ing elements are designed to be compatible with

and exhibit long operational lifetimes when using

clean cold water. Other fluids can signicantly

shorten the life of the packing material through

any number of failure mechanisms, including

chemical reactions or dissolving the packing

material, or offering inadequate lubrication to the

packing. High temperature water is also prob-

lematic, as the packing can only tolerate approx-

imately 125°F water. At elevated temperatures

the packing life decreases substantially.

Suggestion: To understand the effects of a fluid on

pump internals and fluid conductors, it is suggested

to put a univalve part, an o-ring from the valve, a

packing set and a piece of high pressure hose into a

jar of this fluid and observe the effect over time.

Loading...

Loading...