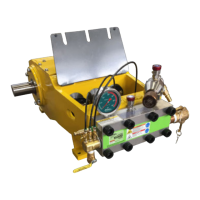

Bareshaft Pump

19

MAINTENANCE

Daily

1. Check Power End Oil Level - Add oil as

necessary. Refer to “Checking Power End Oil

Level” on page 52 for instructions.

2. Check Gland Nut Torque - Ensure the gland

nuts are properly tightened for operation.

Refer to “Checking Gland Nut Torque” on page

33 for instructions.

3. Adjust Water Lubrication System - Ensure

the water is properly adjusted on pressure fed

manifolds equipped with needle valves. Refer

to “Checking the Water Lubrication System” on

page 14.

4. Inspect Rupture Discs - Ensure the rupture

discs are installed and inspect for damage.

Refer to “Rupture Disc Inspection” on page

34. Verify extra replacement discs are on

hand in case of a rupture.

50 Hours

1. Uni-Valve Inspection - Inspect the seals for

damage and the valve seats for deposits, jet-

ting or other damage. Refer to “Valve Inspec-

tion” on page 50 .

2. Inspect Pump Breather - Remove the breath-

er and inspect for dirt and debris. Clean or

replace as necessary.

100 Hours

1. Initial Power End Oil Change - After the rst

100 hours of operation on a new unit, change

the power end oil. Refer to “Changing the

Power End Oil” on page 53.

2. Initial Stufng Box Lubrication Check - Re-

move stufng boxes, clean powerframe bore,

lubricate with anti-seize or petroleum jelly, and

replace stufng boxes.

500 Hours

1. Regular Power End Oil Change - Change

the power end oil. Refer to “Changing the

Power End Oil” on page 53.

2. Regular Stufng Box Lubrication Check

- Remove stufng boxes, clean powerframe

bore, lubricate with anti-seize or petroleum

jelly, and replace stufng boxes.

1000 Hours

1. Journal Bearing Inspection - Replace as

necessary.

Loading...

Loading...