Bareshaft Pump

23

Filter Cartridge Replacement

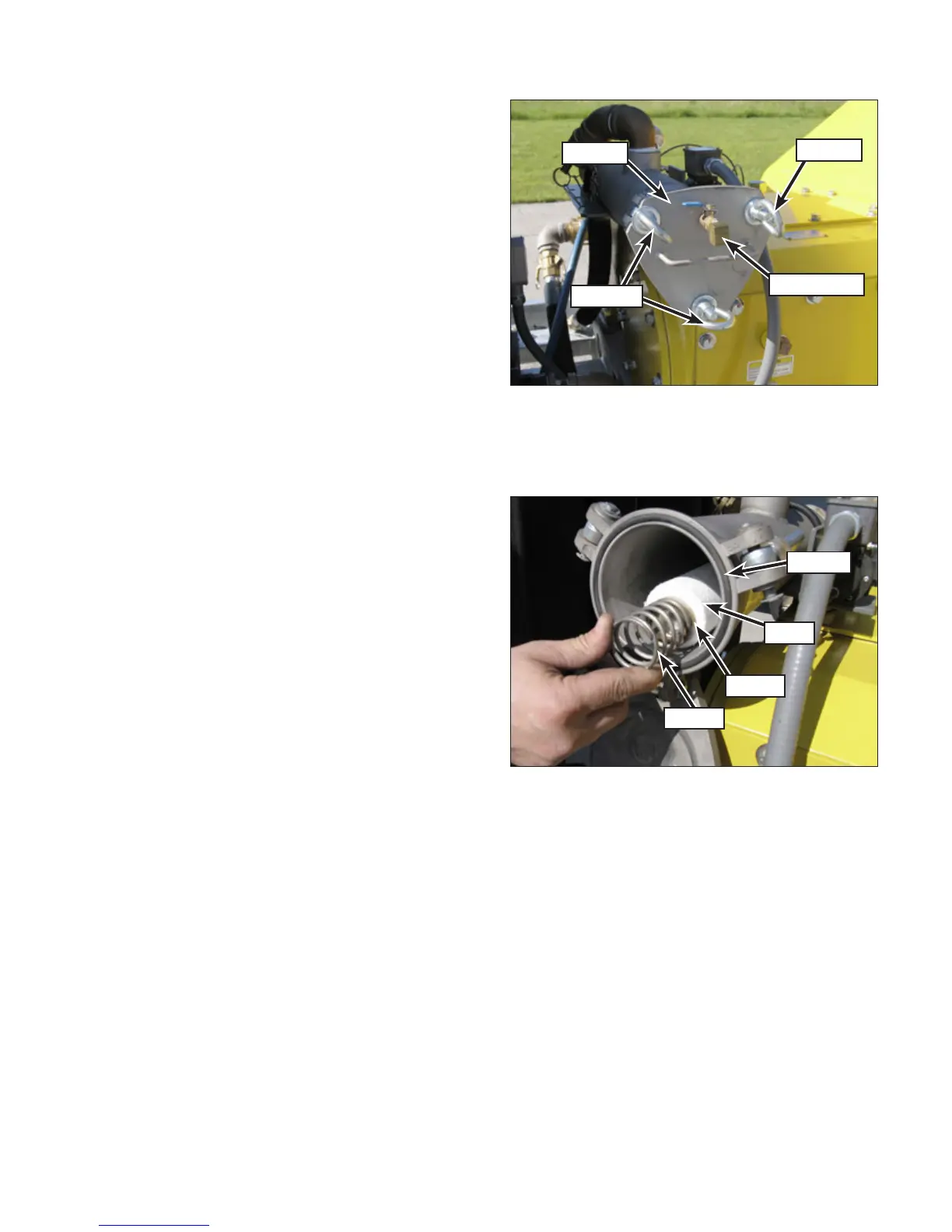

1. Relieve pressure from the housing using the

bleed valve then loosen the three eye-nuts

(Figure 18) on the lter cover.

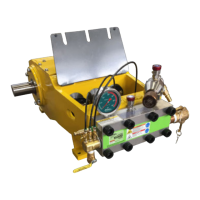

2. Slowly open the cover and capture the spring

(Figure 19) and spring keeper.

3. Remove the lter cartridge.

4. Install the new lter cartridge onto the guide

rod. Ensure the guide rod is correctly seated

into the bottom of the housing.

5. Inspect the O-ring and install a new one if

necessary.

6. Place the spring keeper and spring into place

on the end of the lter cartridge.

7. Move the lter cover into position and tighten

the eye-nuts.

8. Prepare the pump for operation and start the

unit. Start a typical blast operation and record

the following:

• Engine rpm

• Gauge pressure on the secondary lter

9. Save this record for monitoring the status

of the secondary lter. Monitor the pressure

gauge as more hours of operation are ac-

cumulated on the lter cartridge. When the

pressure on the lter gauge has dropped ap-

proximately 7 to 10 psi (0.48 to 0.69 bar) (with

the unit operating at the same rpm as earlier

recorded), the lter must be replaced.

Switch Adjustment

The differential pressure switch will shut down the

unit when the pressure drop across the lter is

approximately 7 to 10 psi (0.48 to 0.69 bar). If the

switch doesn’t close within the 7 to 10 psi (0.48 to

0.69 bar) range, it may need to be adjusted. Contact

Jetstream for switch adjustment instructions.

Uni-Valve Life

The uni-valve seats can be damaged by dirty water.

It is important to change lters regularly to improve

pump performance and prolong valve life. (Nozzles

and bypass cartridges are also adversely affected by

dirty water).

Inspect uni-valve seats regularly to monitor condition

and lap the valve seats when necessary. Refer to

“Valve Lapping” on page 50 for lapping instruc-

tions.

Figure 18: Filter Cover.

Eye Nut

Bleed Valve

Eye Nuts

Cover

Figure 19: Cartridge Removal.

Spring

Keeper

Filter

O-Ring

Loading...

Loading...