Operation Manual

70

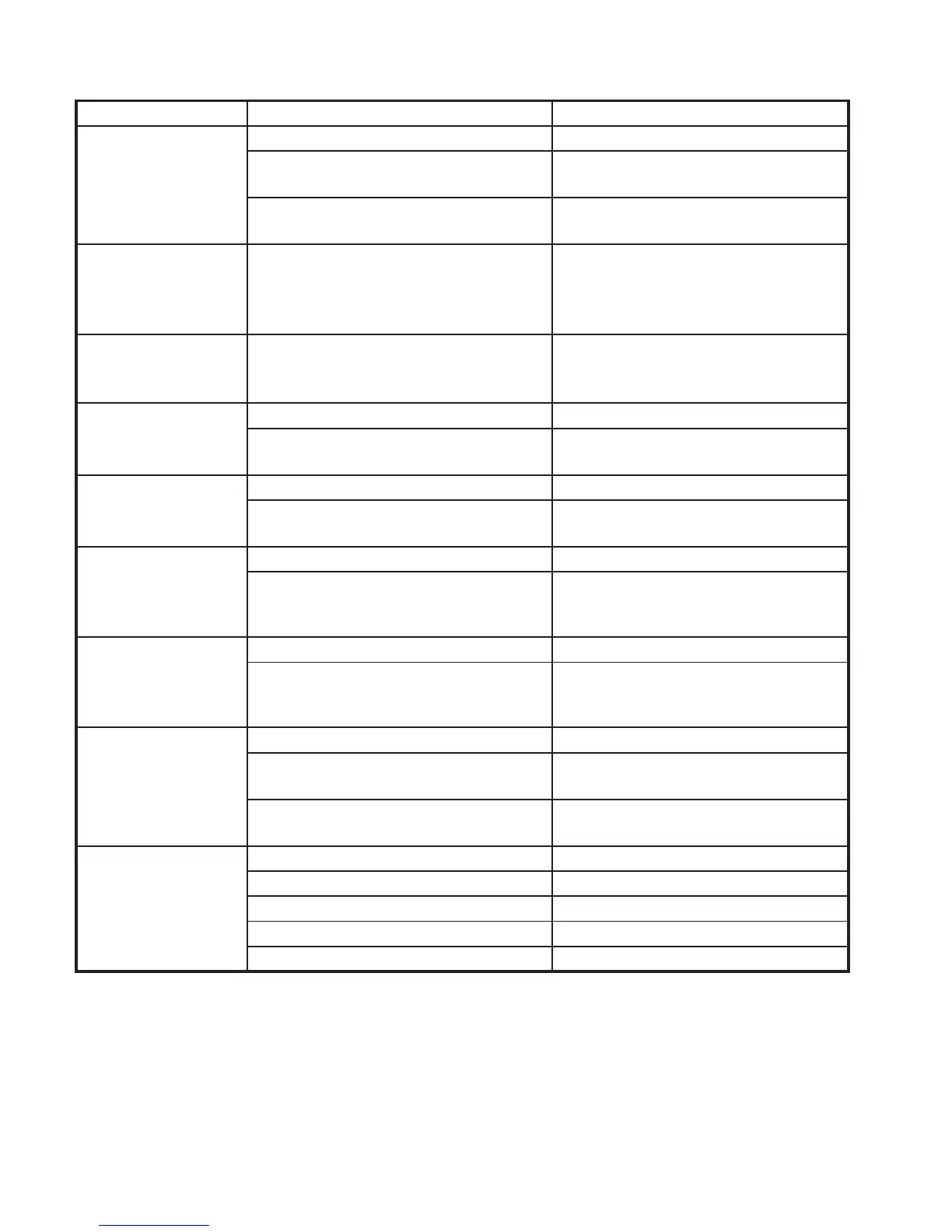

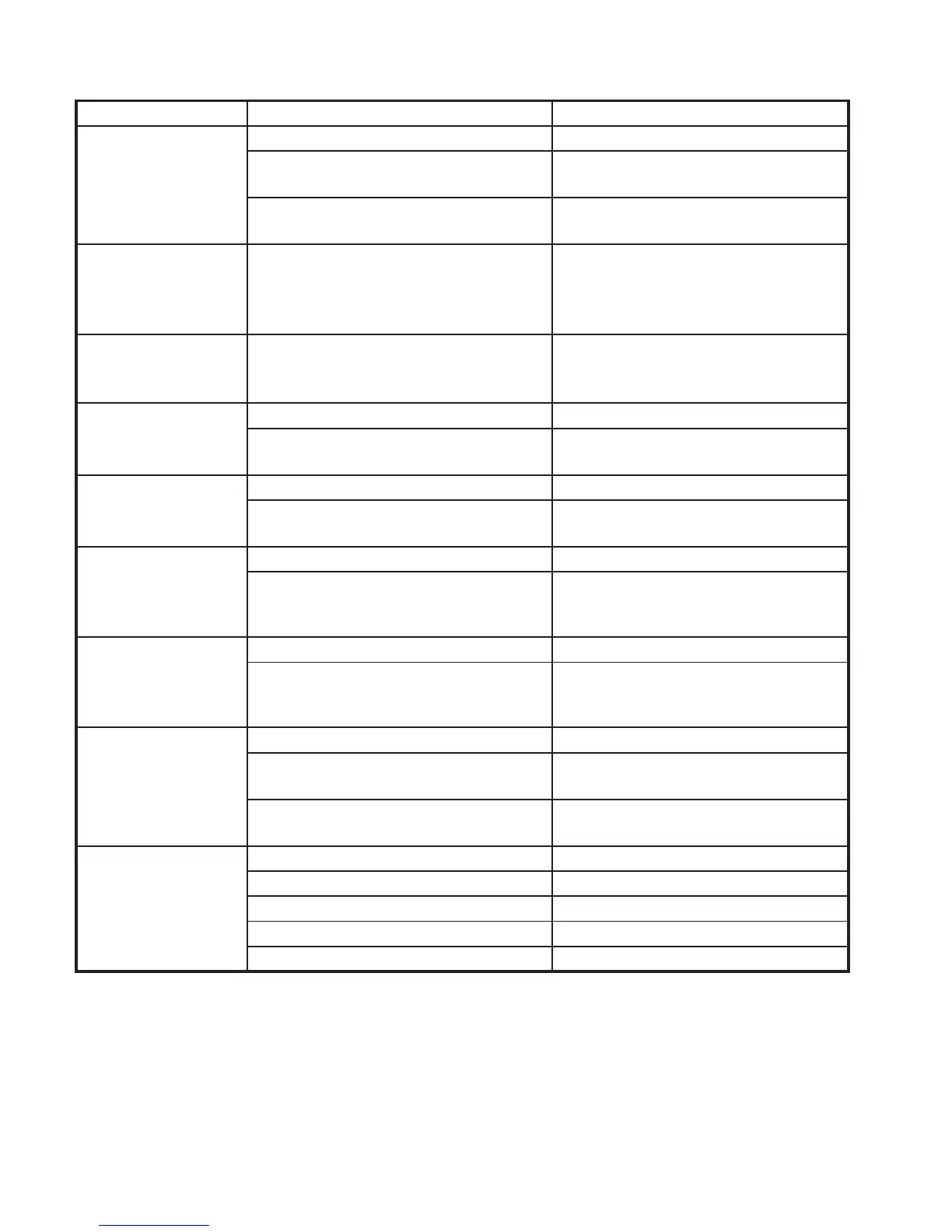

PROBLEM POSSIBLE CAUSE REMEDY

Insufcient water

lubrication

Needle valves not properly adjusted Adjust the needle valves

Air in the system

Open the manifold drain with

pump on

Plugged lines

Remove debris from lubrication

lines

Leakage from

pump

manifold uni-valve

leakage holes

Damaged valve seal Replace seals

Leakage from

discharge tting

leakage holes

Damaged ttings or seals Replace the ttings and/or seals

Pump oil leaking

from breather

Check oil level Add oill as necessary

Verify use of proper oil type

See “Oil Specications” on page

62

Water in pump oil

Cross head oil seal leak Replace seal

Cold oil

Continue to run until oil temp in-

creases to adequate temperature

Engine will not

return to idle when

control gun dump-

ing

Excessive hose back pressure Reduce hose string length

Throttle control piston sticking Repair throttle control unit

Engine will not

increase in speed

when control gun

rst closes

Engine idle speed too low Increase idle speed

Large gun nozzle Decrease nozzle size

Insufcient water

lubrication

Needle valves not properly adjusted Adjust the needle valves

Air in the system

Open the manifold drain with

pump on

Plugged lines

Remove debris from lubrication

lines

Poor packing life

Hot water 125°F max

Insufcient water ow Adjust water ow

Dirty water Clean/replace lter

Scored/pitted plunger Replace plunger

Gland nut loose Tighten nut

Loading...

Loading...