168

7-03

B

7-05

7-06

Operation

CAUTION: MOVE AWAY FROM THE WHEEL

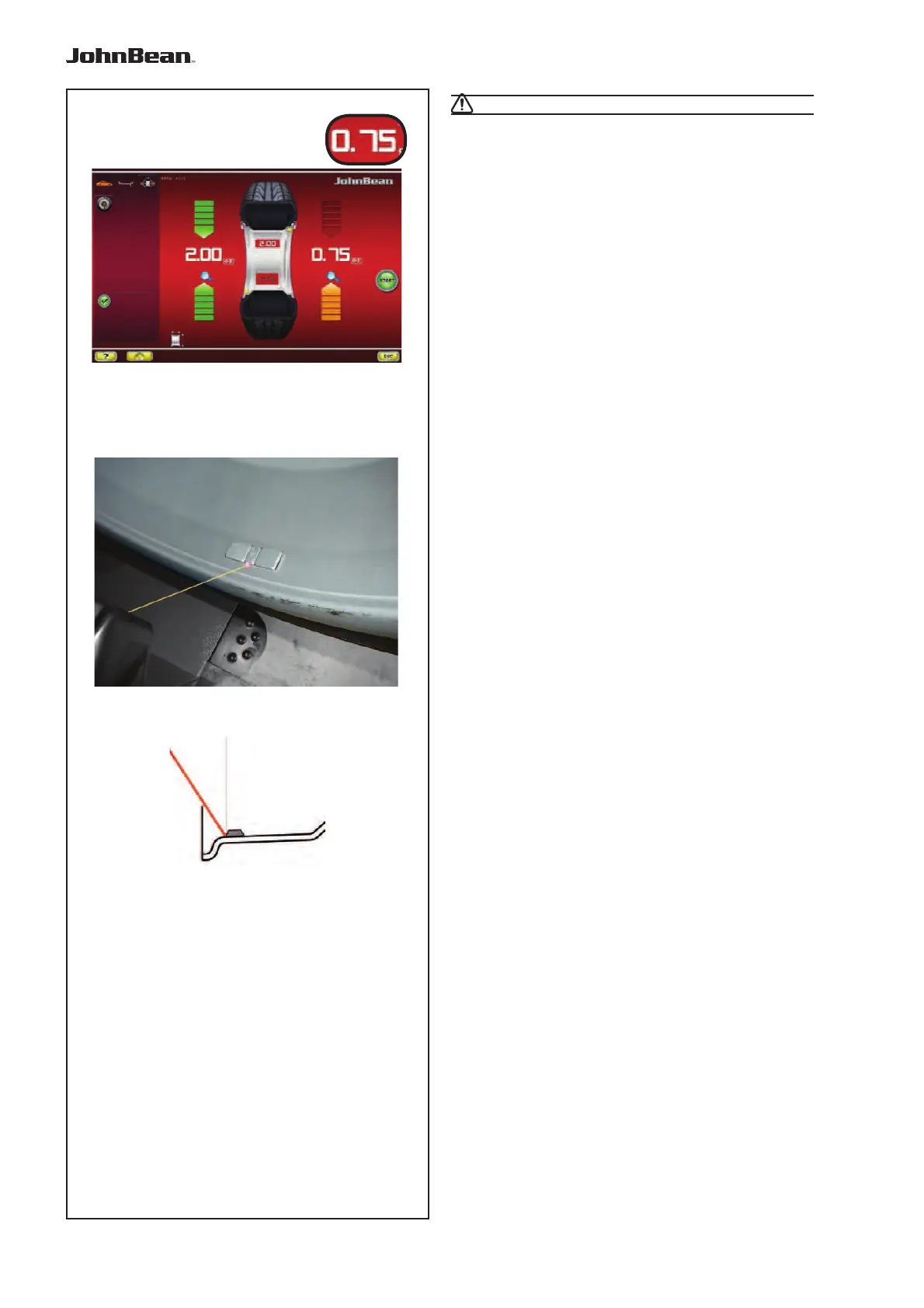

• Press on the value (B, Fig. 7-03), to automatically

bring the wheel to the right-hand WAP position, apply

the adhesive weight on the end of the gauge arm

and fi x it in the suggested position (“1” + “beep”).

— At the end perform a Test Run.

7.0.1.1 Using the Laser Pointer

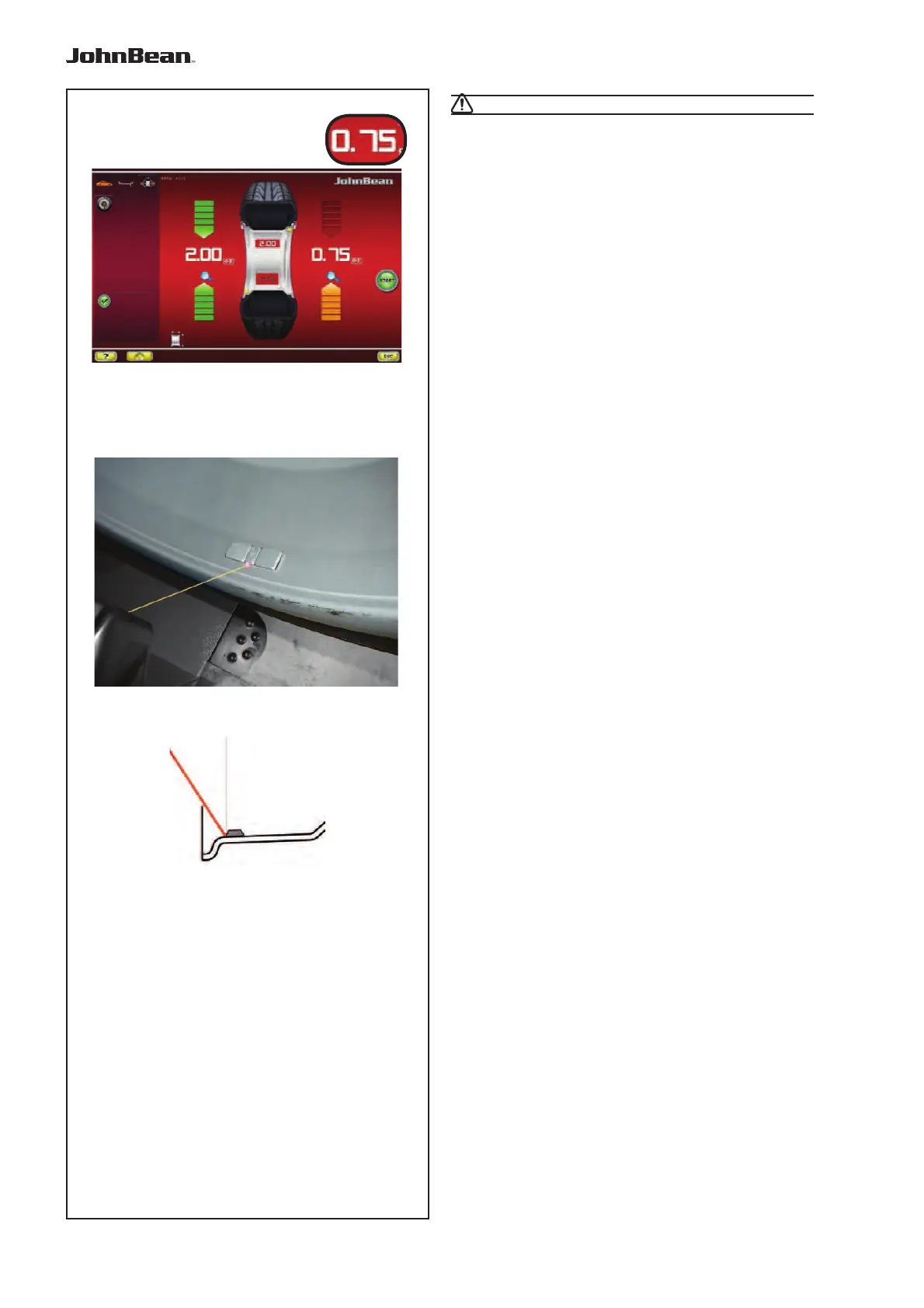

In Alu 2P and Alu 3P modes, with the Laser Pointer

m

ode ac

tive, the correction planes for adhesive

weights are precisely indicated by the laser pointer

directly on the rim (Fig. 7-05).

Note: When the indication is given by the laser

(if

enabled from service)

, the weight must not be

fi tted at 12 o’clock, but at the bottom of the

rim, precisely where indicated by the pointer.

Weights application at about 5 o’clock, on the right of

the laser point (Fig. 7-06).

There are at least two positions where the adhesive

weights can be fi tted, indicated by the Laser pointer,

depending on the wheel type and the balancing mode.

When a run is completed correctly the BALANCING

screen shows the correction values and the position

where the weights must be fi tted.

To make the corrections,

• Select an adhesive weight of the indicated size and

adjust it to the wheel radius by bending.

• If necessary, index the wheel precisely into the

correction position for the left plane. When the

correction position is reached, the two arrows on

the screen light up green.

• Press the pedal of the main shaft lock to hold the

wheel in this position.

• Clean the fitting position before attaching the

adhesive weights.

• Fit the balancing weight and firmly press the

adhesive weight onto the rim.

• Fit the second adhesive weight in the same manner.

The position for fi tting the weights indicated by the

Laser pointer can be varied for each correction

plane.

• See “RELOCATION” (F 6.3.3).

..

_

..........

Loading...

Loading...