RWF II ROTARY SCREW COMPRESSOR UNITS

OPERATION

070.610-IOM (JUN 11)

Page 15

DEMAND PUMP OIL SYSTEM

This system is designed to provide adequate compressor

lubrication when there is low differential oil pressure across

the compressor suction and discharge for some high stage

applications and booster applications as required.

On startup, Quantum™LX will calculate the pressure dif

ferential between the compressor discharge and the main oil

injection port. If this differential is less than 35 psi, then the

demand pump will turn on and will continue to run until 45 psi

differential is obtained. Then, the pump will shut down and

start only when the differential pressure falls below 35 psi.

NOTE: For alarm descriptions and shutdown or cutout

parameters, see publication 090-020 O.

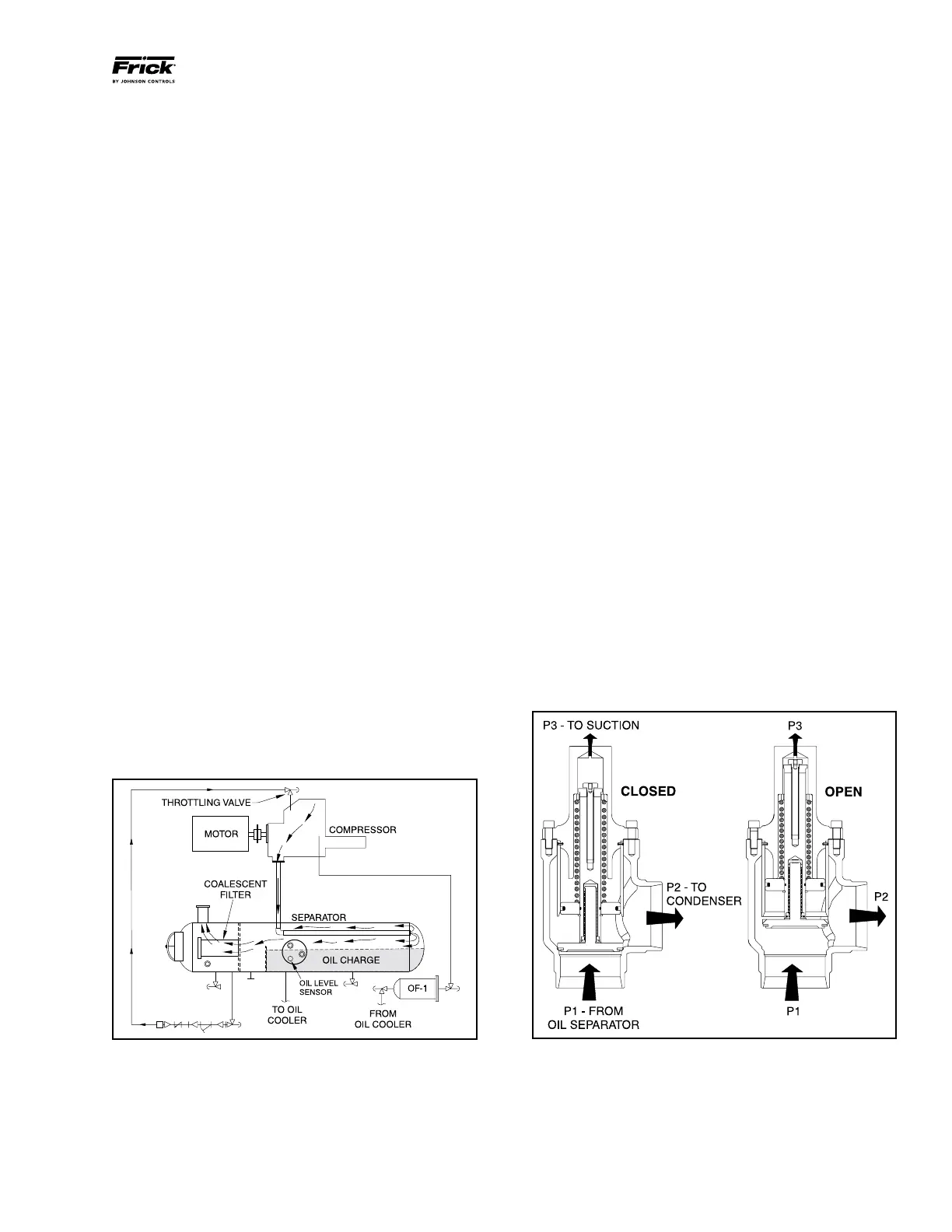

COMPRESSOR OIL SEPARATION SYSTEM

The RWF II is an oil ooded screw compressor. Most of the

oil discharged by the compressor separates from the gas ow

in the oil charge reservoir. Some oil, however, is discharged

as a mist which does not separate readily from the gas ow

and is carried past the oil charge reser voir. One or more

coalescer lter elements then COALESCE the oil mist into

droplets which fall to the bottom of the coalescer section of

the oil separator. See Figure 16. The return of this oil to the

compressor is controlled by a throttling valve on both high

stage and booster applications.

NOTE: Open throttling valve only enough to keep coalescer

end of separator free of oil.

The sight glass located near the bottom of the coales cer sec-

tion of the oil separator should remain empty during normal

operation. If an oil level develops and remains in the sight

glass, a problem in the oil return separation system or com-

pressor operation has developed. Refer to MAINTENANCE

for information on how to correct the prob lem.

NOTE: The normal operating level is midway between the

two sight glasses located midway along the oil separa-

tor shell.

Figure 16 - Oil Separation System

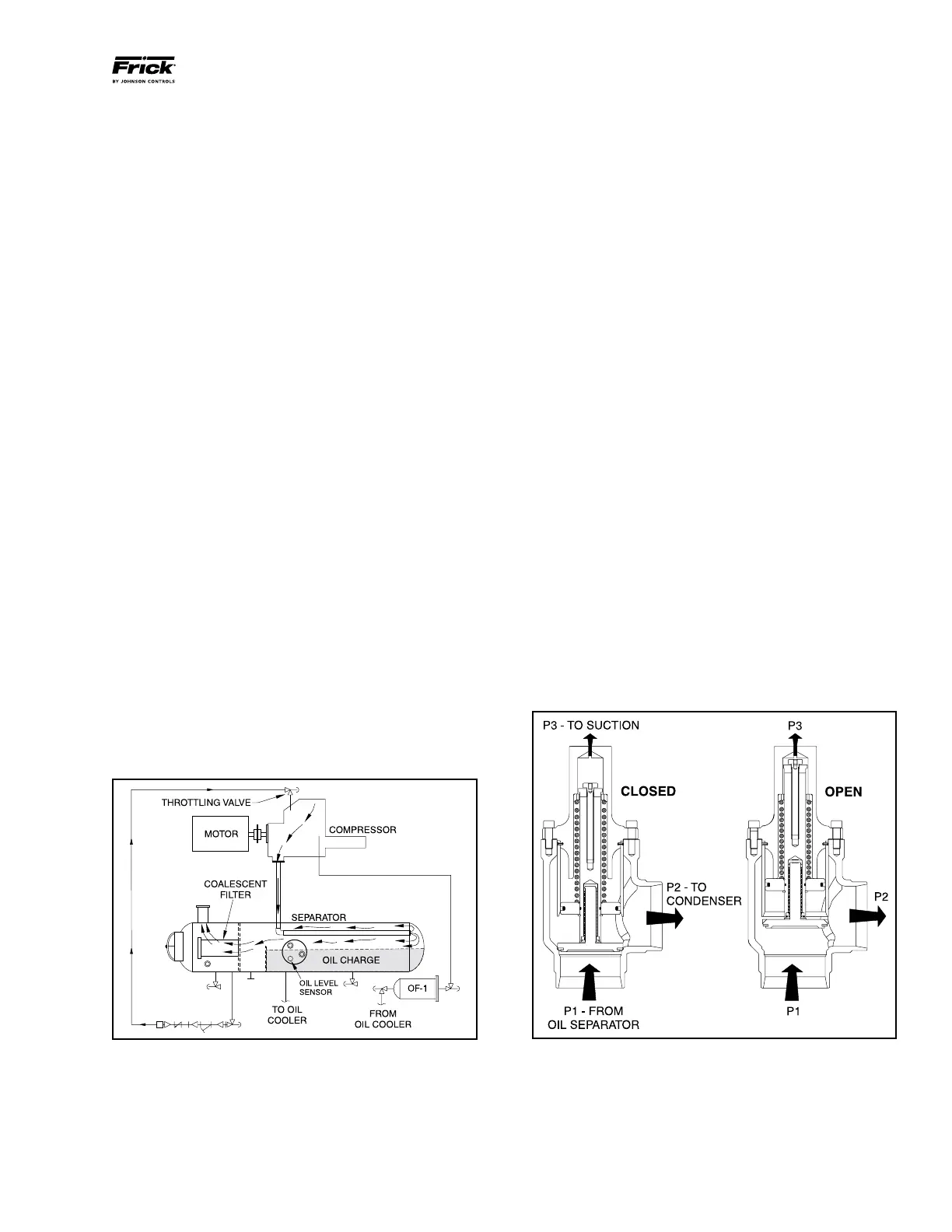

COLD-START SYSTEM

The RWF II package is equipped with a special "coldstart"

discharge check valve (Figure 17) on the gas outlet connec

tion of the oil separator. This valve causes the oil separator

to develop oil pressure rapidly on initial start in order to

lubricate the compressor without requiring an oil pump, even

in cold ambient temperatures with all pressures equalized.

For high-stage packages, the coldstart valve is equipped

with a large spring that creates 30 psi of pressure in the oil

separator (above suction pressure), for lubrication of the

compressor.

Once the compressor is running it will begin to force gas to

the condenser at connection P2. As the condenser heats up it

will begin to rise in pressure as the compressor suction pulls

down in pressure. As soon as differential pressure is devel

oped between the condenser and suction, these pressures

act across a piston inside the coldstart valve to partially

overcome the spring force. When the differential pressure

reaches and exceeds 30 psi, the piston fully overcomes the

spring force and powers the valve fully open for very low

operating pressure drop.

For booster applications, the valve is equipped with a lighter

spring which produces 7 psi oil pressure above suction pres

sure before it fully powers open. An oil pump is required to

ensure compressor lubrication.

The RWF II package is also equipped with a suction check

valve bypass. The oil separator will slowly bleed down to ap

proximate system suction pressure when the unit is stopped.

This allows the compressor drive motor to have an easier

start, and the discharge check valve will seat more tightly. See

the "SUCTION CHECK VALVE BYPASS" section for operation.

NOTE: For alarm descriptions and shutdown or cutout

parameters, see publication 090-020 O.

Figure 17 - Cold-Start Valve

Loading...

Loading...