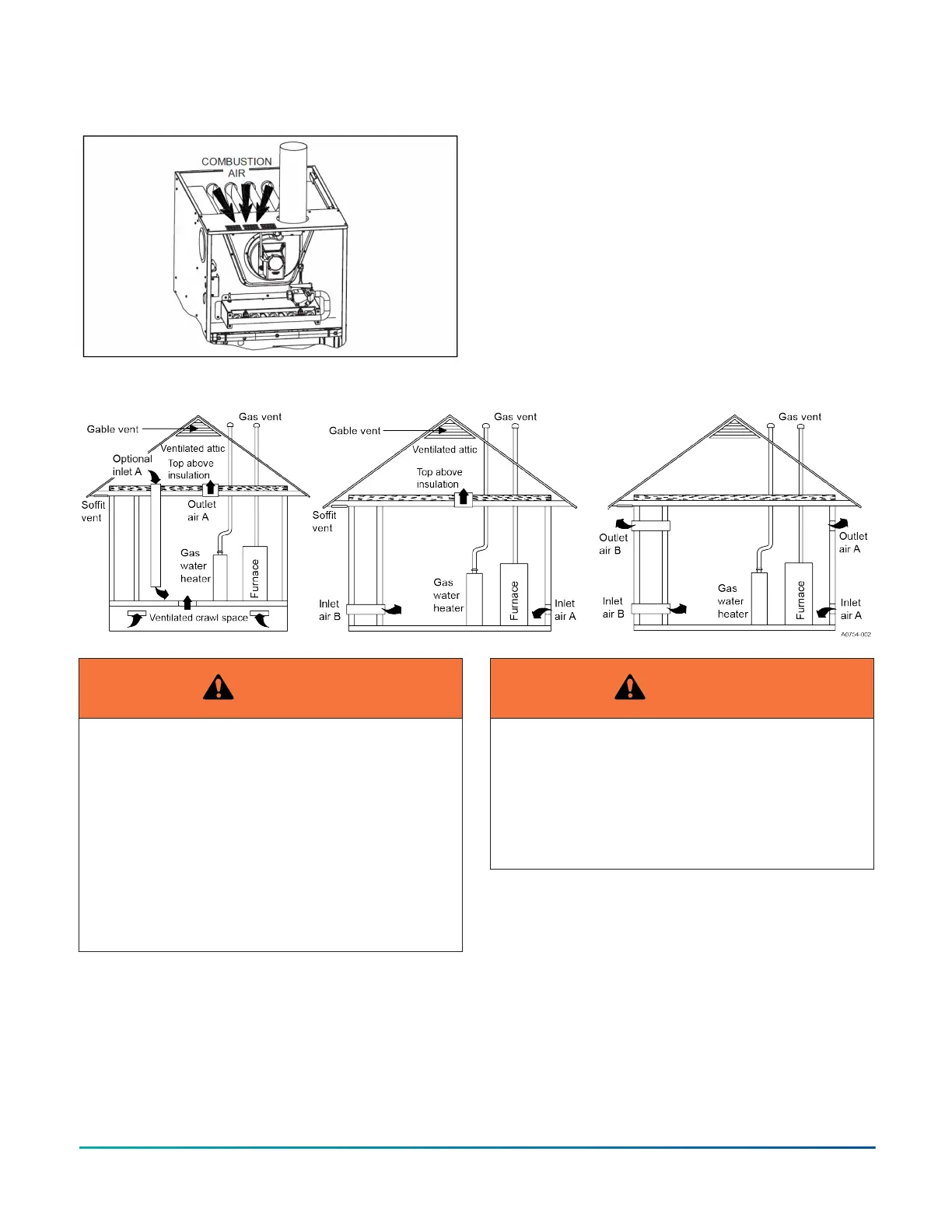

Figure 25: Combustion airflow path through the

furnace casing to the burner compartment

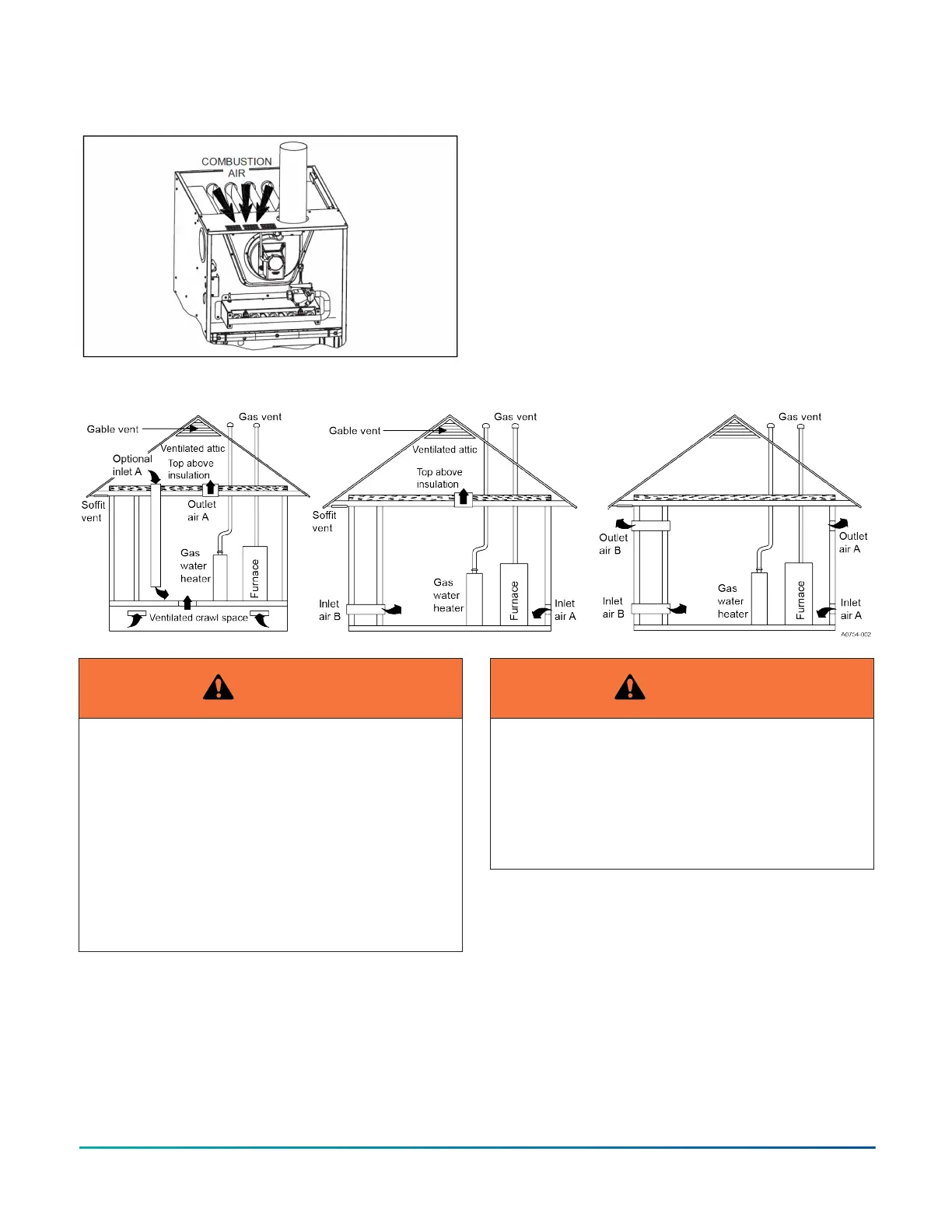

Figure 26: Combustion airflow path through the furnace casing to the burner compartment

WARNING

This type of installation requires that the supply

air to the appliance(s) be of a sufficient amount to

support all of the appliance(s) in the area. Operation

of a mechanical exhaust, such as an exhaust fan,

kitchen ventilation system, clothes dryer or fireplace

may create conditions requiring special attention to

avoid unsatisfactory operation of gas appliances. A

venting problem or a lack of supply air will result in a

hazardous condition, which can cause the appliance

to soot and generate dangerous levels of CARBON

MONOXIDE, which can lead to serious injury, property

damage and / or death.

WARNING

Examine the heat exchanger, vent pipe, combustion

air passages, vent connectors, and chimney to be

sure they are clear and free of obstructions.

Note: Proper orientation on the heat exchanger is

for the compressed heat transfer blade portion to be

up and away from the burner section, towards the air

leaving end of the furnace.

An unconfined space is not less than 50 ft

3

(1.42 m

3

)

per 1,000 Btu/h (0.2928 kW) input rating for all of the

appliances installed in that area.

Rooms communicating directly with the space containing

the appliances are considered part of the unconfined

space, if doors are furnished with openings or louvers.

A confined space is an area with less than 50 ft

3

(1.42

m

3

) per 1,000 Btu/h (0.2928 kW) input rating for all of

the appliances installed in that area. The following must

be considered to obtain proper air for combustion and

ventilation in confined spaces.

Installation Manual: RL18 Single-Stage Standard ECM Residential Gas Furnaces (Non-condensing Multi-position Standard

Low NOx)

24

Johnson Controls Ducted Systems

Loading...

Loading...