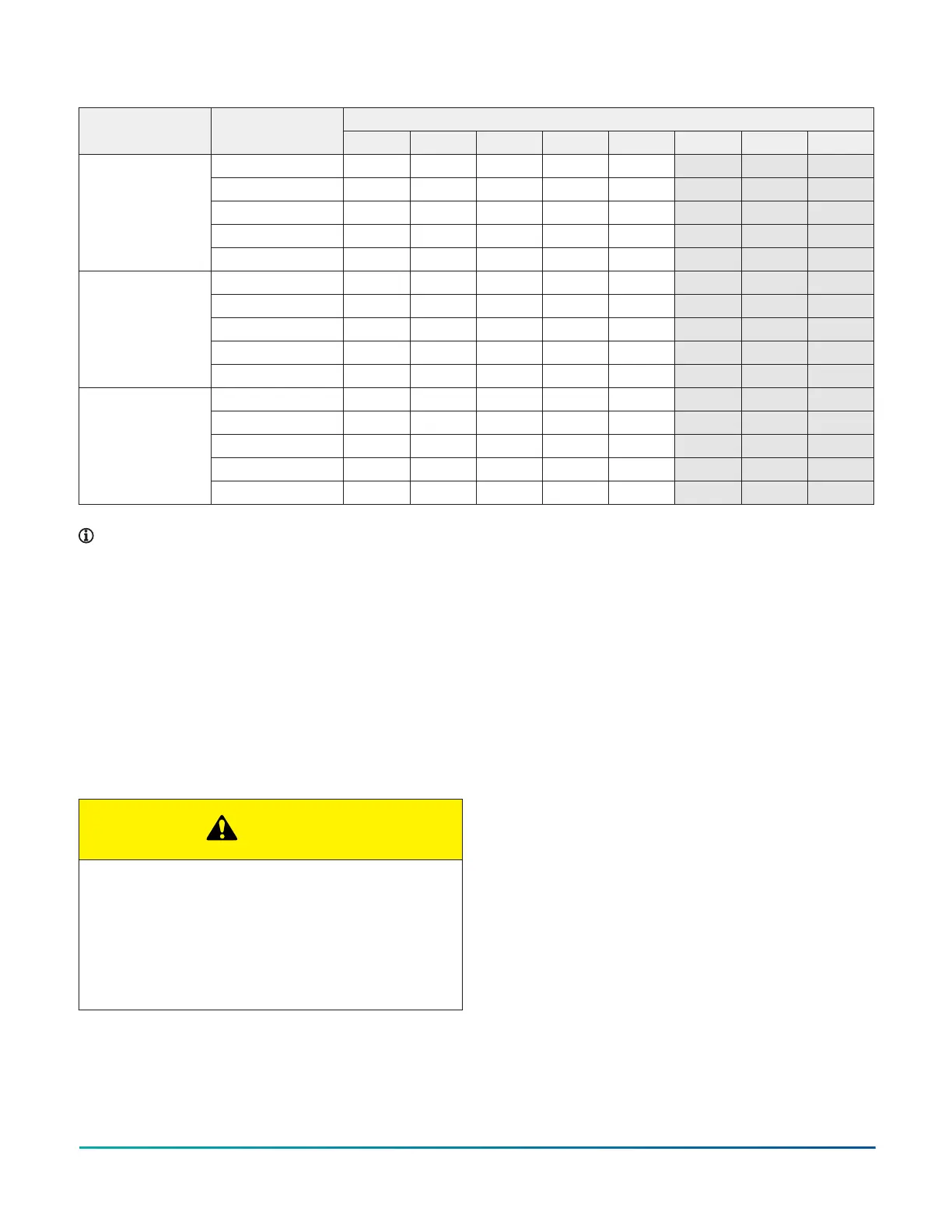

Table 14: Blower performance CFM - any position (without filter)

Airflow data (SCFM) external static pressure (in. W.C.)Model Speed

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

High 2050 2025 1975 1950 1925 1900 1850 1800

Medium High 1850 1800 1775 1750 1700 1675 1625 1600

Medium 1700 1675 1650 1600 1550 1525 1475 1450

Medium Low 1475 1425 1400 1350 1325 1275 1250 1200

120C16

Low 1175 1125 1075 1025 1000 950 900 875

High 2000 1925 1875 1825 1775 1725 1675 1625

Medium High 1850 1775 1725 1675 1600 1550 1500 1450

Medium 1700 1625 1575 1500 1450 1400 1325 1275

Medium Low 1475 1400 1350 1275 1225 1175 1100 1050

120C20

Low 1250 1175 1100 1025 950 875 800 725

High 2100 2050 2000 1975 1925 1875 1850 1800

Medium High 1925 1875 1825 1800 1775 1725 1675 1650

Medium 1750 1725 1675 1625 1600 1550 1500 1475

Medium Low 1625 1575 1525 1475 1425 1375 1325 1300

130D20

Low 1325 1250 1200 1150 1075 1025 950 900

Note:

• Airflow is expressed in standard cubic feet per minute (SCFM).

• Motor voltage is at 115 V.

• Not all speeds are recommended for use as heating speeds.

Safety controls

Control circuit fuse

A 3 A fuse is provided on the control circuit board to

protect the 24 V transformer from overload caused by

control circuit wiring errors. This is an ATO 3 automotive-

type fuse and is located on the control board.

Blower door safety switch

CAUTION

Main power to the unit must still be interrupted at the

main power disconnect switch before any service

or repair work is to be done to the unit. Do not rely

upon the interlock switch as a main power

disconnect.

Blower and burner must never be operated without

the blower panel in place.

This unit is equipped with an electrical interlock switch

mounted in the blower compartment. This switch

interrupts all power at the unit when the panel covering

the blower compartment is removed.

Electrical supply to this unit is dependent upon the panel

that covers the blower compartment being in place and

correctly positioned.

Rollout switch controls

These controls are mounted on the burner assembly.

If the temperature in the area surrounding burner

exceeds its set point, the gas valve is de-energized. The

operation of this control indicates a malfunction in the

combustion air blower, heat exchanger, or a blocked vent

pipe connection. Corrective action is required. These are

manual reset controls that must be reset before operation

can continue.

Pressure switches

This furnace is supplied with a pressure switch, which

monitors the flow through the combustion air/vent

piping and condensate drain system. This switch de-

energizes the gas valve if any of the following conditions

are present:

• Blockage of vent piping or terminal

• Failure of combustion air blower motor

Installation Manual: RL18 Single-Stage Standard ECM Residential Gas Furnaces (Non-condensing Multi-position Standard

Low NOx)

34

Johnson Controls Ducted Systems

Loading...

Loading...