Operating manual - SAB 120-151 A-frame (including ATEX)

008668 en 2019.08

21/61

Safety precautions

Cooling water system

Warning!

The recirculation water system may contain chemicals or biological contaminants, including le-

gionella, which can be harmful if inhaled or ingested. Water systems should only be operated with

an effective biological treatment programme.

4.3 Safety during maintenance and service

• Personnel must be competent according to national safety rules and regulations and per-

form the maintenance work according to EN 378.

• Read chapter 4. Safety precautions before opening the compressor and other parts of the

refrigeration plant.

• It is recommended to remove all main fuses. Switch off all electric components on the

compressor/unit before starting the dismantling/servicing process and lock the main

switch.

• Make sure that the motor cannot start up inadvertently.

• Make sure that there is no over-pressure and no refrigerant in the part to be dismantled.

Close all necessary stop valves.

• Use the prescribed tools, and check that they are properly maintained and in good work-

ing condition. In explosion-proof areas, use tools suited for this specific purpose.

• Use only Johnson Controls Denmark original spare parts; other parts may impair the

safety of the compressor/unit.

• When performing maintenance, the main switch must be locked.

• Use gloves and protective goggles, and make sure to have a gas mask close at hand. Also

use electrical protection equipment and tools suited for electrical operation purposes.

ATEX:

• All parts should be electrically conductive to avoid sparking when static electricity builds

up.

• Materials should only contain a limited percentage of light metals.

• Original parts supplied by Johnson Controls Denmark must not be replaced by unspecified

parts that are not ATEX approved.

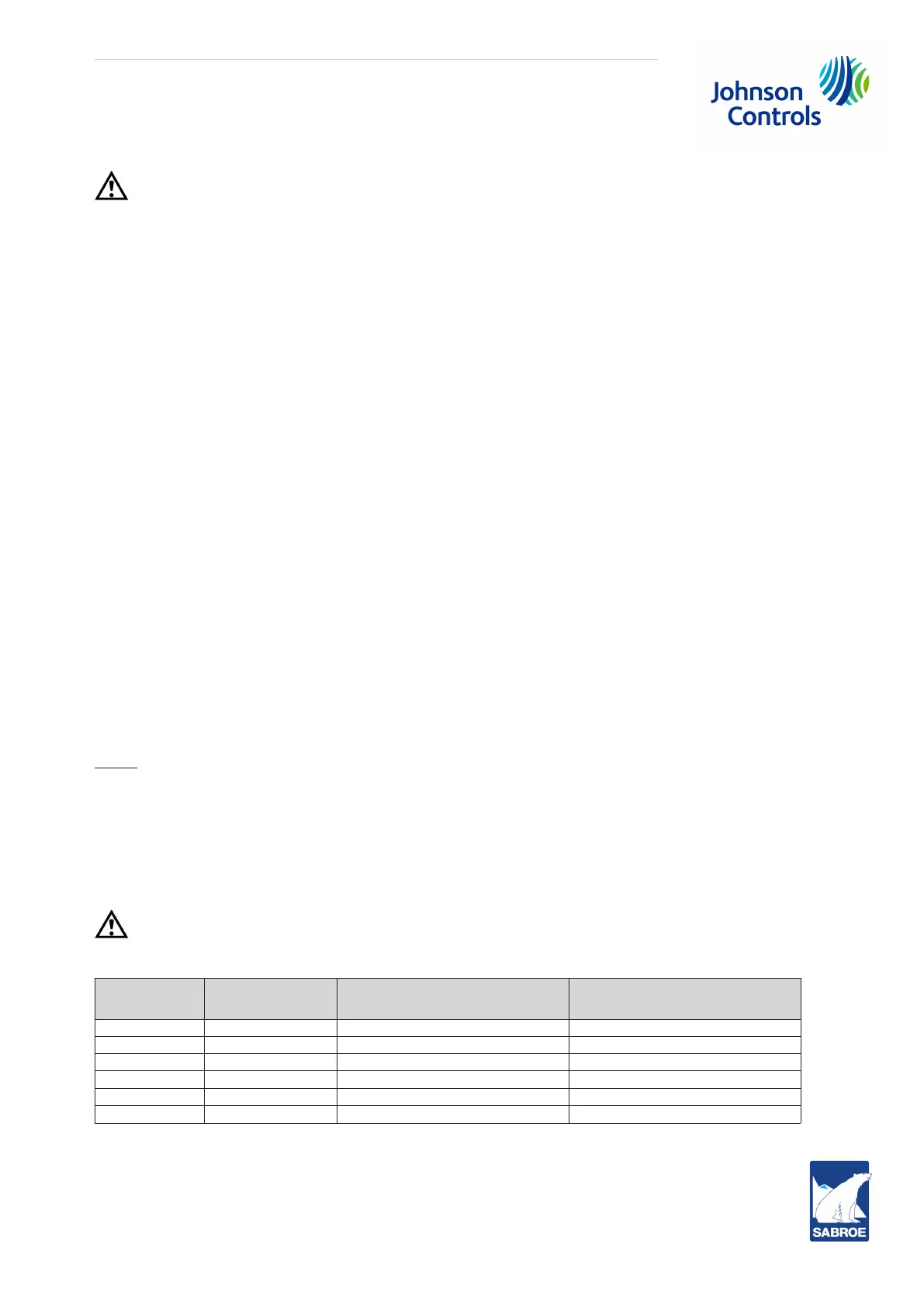

Warning!

On ATEX-executions, the limits in Table 4 must always be respected.

Temp. class Max. surface

temp.

Max. temperature of oil to

shaft seal

Min. ignition temperature

of oil

T1 450°C 380°C 500°C

T2 300°C 230°C 350°C

T3 200°C 130°C 250°C

T4 135°C 65°C 185°C

T5 100°C 30°C 150°C

T6 85°C 15°C 135°C

Table 4: Temperature classes - screw compressors

Loading...

Loading...