5594752-UIM-C-1119

Johnson Controls Ducted Systems 13

SECTION VI: TWINNING AND STAGING

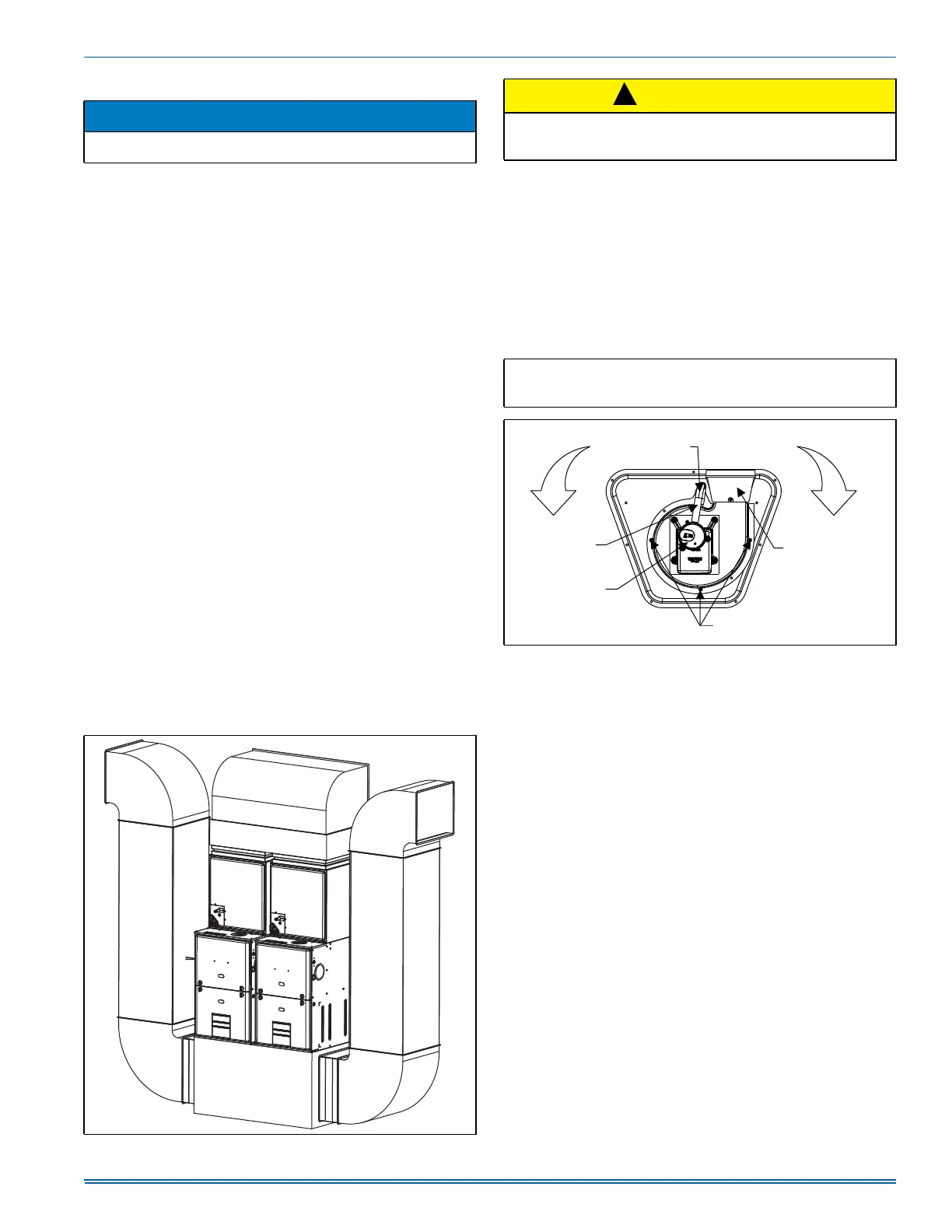

In applications where more heating capacity or more airflow capacity is

needed than what one furnace can deliver, twinning can be used to

make two furnaces operate in tandem (as long as the two furnaces

have the same model number). When two identical furnaces are

installed using the same duct system, it is very important that the two

furnace circulating air blowers operate simultaneously at all times. If

one blower starts before the second blower, the duct system will

become pressurized and the blower on the second furnace may turn

backwards causing the second furnace to overheat, resulting in dam-

age to the furnace. Twinning is used to make two furnaces operate in

tandem, using one duct system, one room thermostat and causing both

furnaces blowers to turn on and off simultaneously.

TWINNING DUCT SYSTEM

Twinned furnaces must only be applied on a common duct system. A

single air supply plenum must be used for both furnaces and indoor

coil(s). Separate plenums and supply ducts systems cannot be utilized.

A single return air plenum, common to both furnaces must be used. It is

suggested that a return platform be utilized, with bottom air entrance

into each furnace. If a side entrance return system is used, the common

return duct must be divided equally so as to supply each furnace with

an equal amount of return air.

Both furnaces must be identical models in both heating capacity and

CFM capacity. Both furnaces must be operated on the same motor

speed taps. Detailed and specific indoor blower motor wiring and con-

trol wiring information can be found in Source 1 twinning kit S1-

33103764000 installation instructions. See typical application, Figure

14.

If furnace staging is desired with two single stage furnaces on a com-

mon duct, where the gas burner on the first furnace operates on W1

and the gas burner on the second furnace operates on W2, then the

use of an air-mixing device in the plenum to mix the air from both fur-

naces is strongly recommended. The mixing device must be installed

before any ducts that supply air to occupied spaces. Twinning causes

both indoor fans to operate simultaneously. If a mixing device is not

used, any ducts that are connected down stream from the furnace that

is not operating in heat mode will be supplying cold air to the occupied

spaces.

SECTION VII: VENT SYSTEM

VENT CONNECTIONS

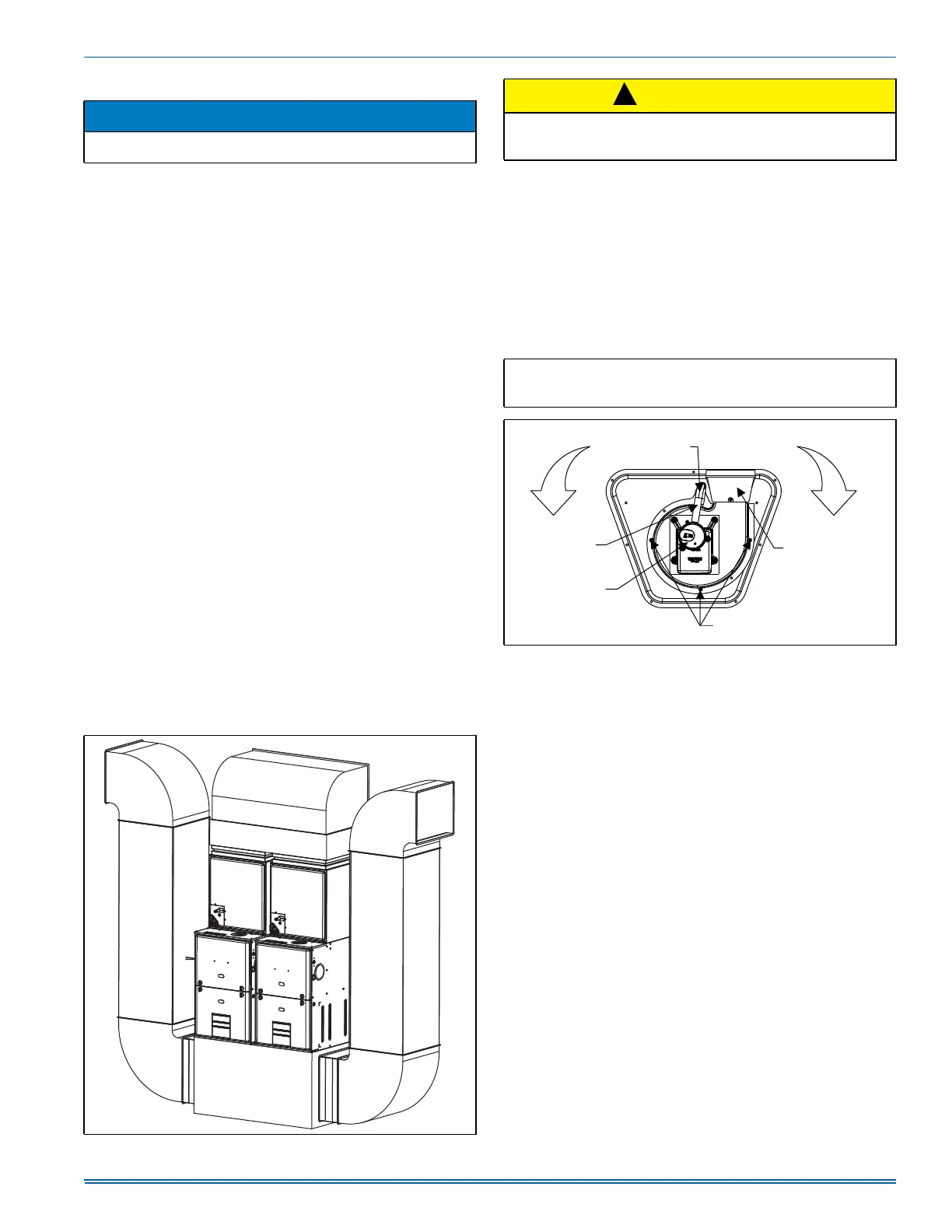

All models are provided with a flue transition that is sized for 4” diame-

ter vent connections. If a larger size vent connector is required, that

connection must be installed external to the furnace. Figure 15 shows

the furnace as it is shipped from the factory. To convert to a horizontal

or downflow position, remove the four screws that secure the inducer

assembly and rotate 90º being careful not to damage the gasket. Rein-

stall screws. Remove cap from appropriate vent outlet location on the

cabinet, cut insulation in cabinet to same size as the hole provided and

reinstall cap in the hole in the top panel.

CATEGORY 1 - 450 F. MAX. VENT TEMP.

The venting system must be installed in accordance with Section 5.3,

Air for Combustion and Ventilation, of the National Fuel Gas Code

Z223.1/NFPA 54 (latest edition), or Sections 7.2, 7.3 or 7.4 of CSA

B149.1, National Gas and Propane Codes (latest edition) or applicable

provisions of the local building code and these instructions.

The furnace shall be connected to any type of B, BW or L vent connec-

tor, and shall be connected to a factory-built or masonry chimney. The

furnace shall not be connected to a chimney flue serving a sepa-

rate appliance designed to burn solid fuel.

It is recommended that the appliance is installed in a location where the

space temperature is 32ºF (0ºC) or higher. If the appliance is installed in

a location where the ambient temperature is below 32ºF (0ºC), the com-

bustion byproducts could condense causing damage to the appliance

heat exchanger.

This appliance may be common vented with another gas appliance for

residential installations as allowed by the codes and standards listed in

these instructions.

Non-HUD approved Modular Homes must be vented with an approved

roof jack and may not be common vented with other appliances.

VENTING

Category I venting consists of vertically venting one or more appliances

in B-vent or masonry chimney (as allowed), using single wall metal pipe

or B-vent connectors. Type B-vent system extends in a general vertical

direction and does not contain offsets exceeding 45º. A vent system

having not more than one 60º offset is permitted.

NOTICE

For twinning applications, Source 1 twinning kit S1-33103764000

MUST be used.

FIGURE 14: Twinned Furnaces

$

CAUTION

If a return duct is connected to only one furnace (with a connection

between the two furnaces) an imbalance in the airflow will occur and

the furnace furthest from the return plenum will overheat.

IMPORTANT: In downflow applications, do not block the combustion

air inlet. The furnace must be installed on a coil cabinet or subbase to

allow combustion air to enter the burner compartment.

FIGURE 15: Combustion Air Inducer

!

COMBUSTION AIR INDUCER

90° 90°

Mounting Screw

(Remove)

Flue Transition

(Do Not Remove)

Mounting Screw

(Remove)

Pressure

Switch

Pressure Switch

Tube Routing

Loading...

Loading...