Powered by

Eaton’s Technology VSD Series Quick Start Guide

LIT-1201858

For more information visit: www.johnsoncontrols.com 17

November 2009

Appendix C — Interlock Damper Start Example

Interlock Damper Start Example Using PID Duct Static Control Signal

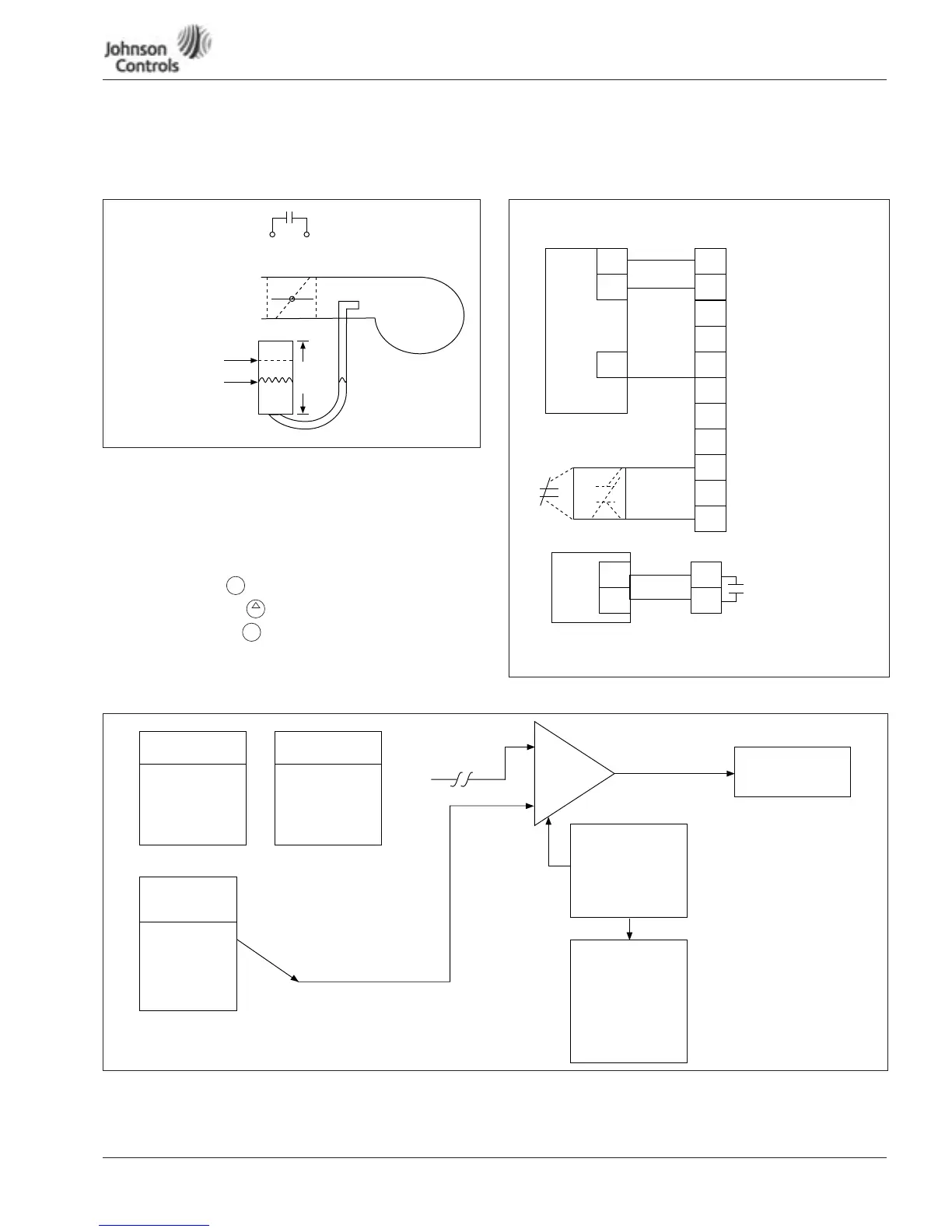

Figure 13: Interlock Damper Start with PID Duct Static Example

Step 1. Wire load line, digital I/O per example and verify

voltage and amperage

Step 2. Static check drive SCR, IGBT, DC Bus per Static Check,

Page 20 and 21

Step 3. Start-up wizard (Duct static application)

Step 4. Select hand to check motor rotation

Step 5. Press Start and to increase speed in Hand mode

Step 6. Select Remote to run in Auto

Step 7. Tune PID per diagram below

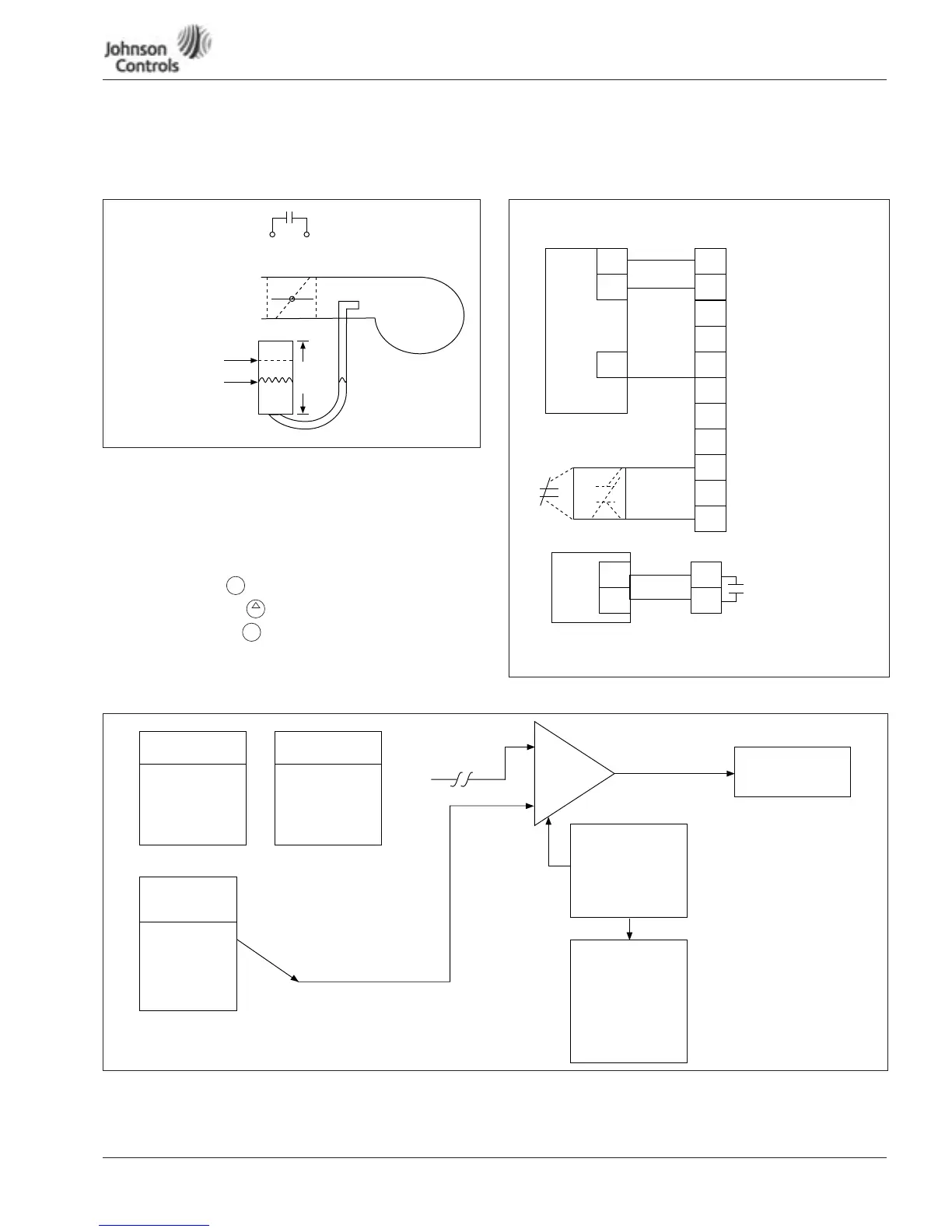

Figure 14:

Figure 15: PID Flow Chart

Max WC = 2.5”

Main WC = 0.0”

Setpt WC = 2.0“

To Drive Damper

Interlock Terminals

10 12

Fan

Set PT Keypad Default

Actual PI Feedback

A1-1, 0-10 Vdc Default

2.50”

Water

H

2

O

Error

HOA

+

HOA

2

3

2

3

6

6

8

10

12

0 ñ 10 Vdc

Actual

+

-

24 Vdc

Out

Com

Power

Pressure

X Drive

Factory

Jumper

22

23

A1-1+ 0 ñ 10 Vdc

A1-1- Default

24 Vdc Control

Close Terminal

(6 ñ 8) to Start VFD

D1-1

D1-3 Run Permisive

Damper Interlock

(Default)

24 Vdc Control Voltage

Closed on

Run

Default

8 A/24 Vdc

.8 A/125 Vac

.4 A/250 Vac

OPTA9 Slot A

OPTA2 Slot B

Damper Actuator

Input Terminals

Hand Mode (M1)

P1.1.13

A1 - 1

A1 - 2

Keypad

Motor Pot

Actual PI (M1)

Feedback

P1.1.17

A1 - 1

A1 - 2

Fieldbus

Min A1-1, A1-2

Max A1-1, A1-2

Ave A1-1, A1-2

Auto Mode (M1)

P1.1.15

A1 - 1

A1 - 2

Keypad

Motor Pot

Fieldbus

PID Gain (M1)

P1.1.20

PID I-Time

P1.1.21

PID Control D

P1.1.22

Output

Frequency

PI

Error

Amp

PI Setpoint

PI Ref Rise T

P1.1.23

PI Ref Fall Time

P1.1.24

PI Ref Max

P1.1.19

PI Ref Min

P1.1.18

OR

P10 Parameter

Adjustments

Sensor

Output

Signal

Sensor Parameter

Adjustments

Loading...

Loading...