JOHNSON CONTROLS

104

FORM 150.62-NM6 (103)

SYSTEM LEAD/LAG

Lead/lag between systems may be selected to help

equalize average run hours between systems on chill-

ers with 2 refrigerant systems. This may be programmed

under the OPTIONS key. Auto lead/lag allows automatic

lead/lag of the two systems based on average run hours

of the compressors in each system. Manual lead/lag

selects specically the sequence in which the micro

starts systems.

COMPRESSOR LEAD/LAG

The compressors within a system rotate starts in se-

quence 1, 2 or 1, 2, 3 with wraparound. The longest-off

compressor in a system will start rst, and the longest-

running compressor in a system will turn off rst. When

unloading, the system with the most compressors on,

unloads rst. The lag system will shut down a com-

pressor rst when equal numbers of compressors are

operating in each system. The micro will not attempt to

equalize run time of compressors in a system.

Once the second system has started a compressor, the

micro will attempt to equally load each system. Once this

occurs, loading will alternate between systems.

If Soft Start is enabled on European models with this

option, compressor lead/lag will function as outlined in

Option 12 under the Options key.

ANTI-RECYCLE TIMER

The programmable anti-recycle timer assures that sys-

tems do not cycle. This timer is programmable under the

PROGRAM key between 300 - 600 seconds. Whenever

possible, to reduce cycling and motor heating, the anti-

recycle timer should be adjusted to 600 seconds. The

programmable anti-recycle timer starts the timer when

the rst compressor in a system starts. The timer begins

to count down. If all of the compressors in a circuit cycle

off, a compressor within the circuit will not be permitted to

start until the anti-recycle timer has timed out. If the lead

system has run for less than 5 minutes, 3 times in a row,

the anti-recycle timer will be extended to 10 minutes.

ANTI-COINCIDENCE TIMER

This timer is not present on single-system units. Two

timing controls are present in software to assure com-

pressors within a circuit or between systems, do not start

simultaneously. The anti-coincidence timer assures there

is at least a one minute delay between system starts on

2-circuit systems. This timer is NOT programmable. The

load timers further assure that there is a minimum time

between compressor starts within a system.

EVAPORATOR PUMP CONTROL

The evaporator pump dry contacts (CTB2 – terminals

23 - 24) are energized when any of the following con-

ditions are true:

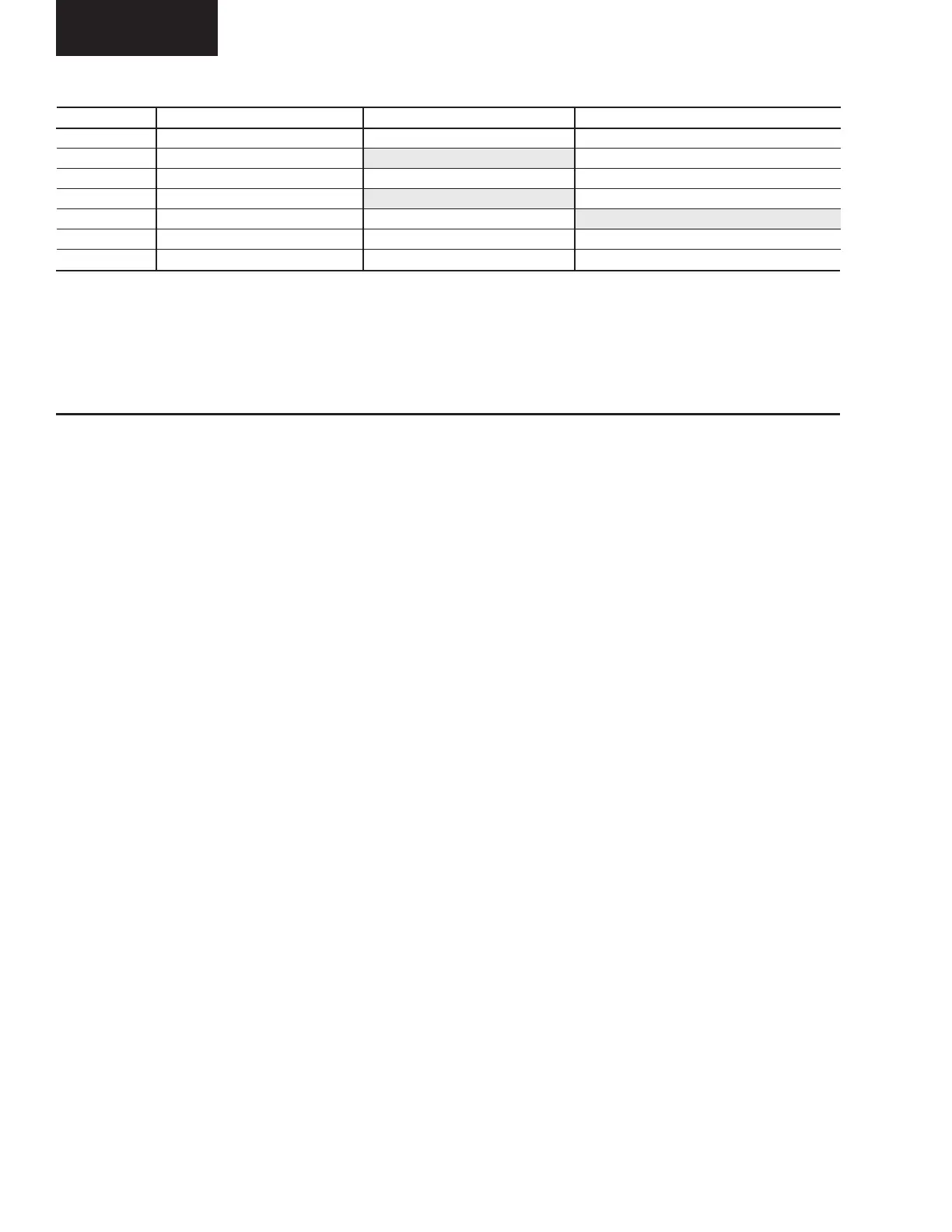

Unit Controls

Notes:

1. Step 1 is Hot Gas Bypass and is skipped when loading occurs. Hot Gas Bypass operation is inhibited during Pumpdown.

2. Step 3 is skipped when loading occurs.

3. Step 4 is skipped when unloading occurs.

TABLE 26 – RETURN CHILLED LIQUID CONTROL FOR 4 COMPRESSORS (6 STEPS)

*STEP COMPRESSOR COMPRESSOR ON POINT COMPRESSOR OFF POINT

0 0 SETPOINT SETPOINT

1 1 W/HGB SP + CR/8 (Note 1) SETPOINT

2 1 NO HGB SP + CR/4 SP + CR/8

3 2 SP + 2*CR/4 (Note 2) SP + CR/4

4 2 SP + 2*CR/4 SP + CR/4 (Note 3)

5 3 SP + 3*CR/4 SP + 2*CR/4

6 4 SP + CR SP + 3*CR/4

* STEP can be viewed using the OPER DATA key and scrolling to COOLING DEMAND.

Loading...

Loading...