JOHNSON CONTROLS

123

FORM 150.62-NM6 (103)

.

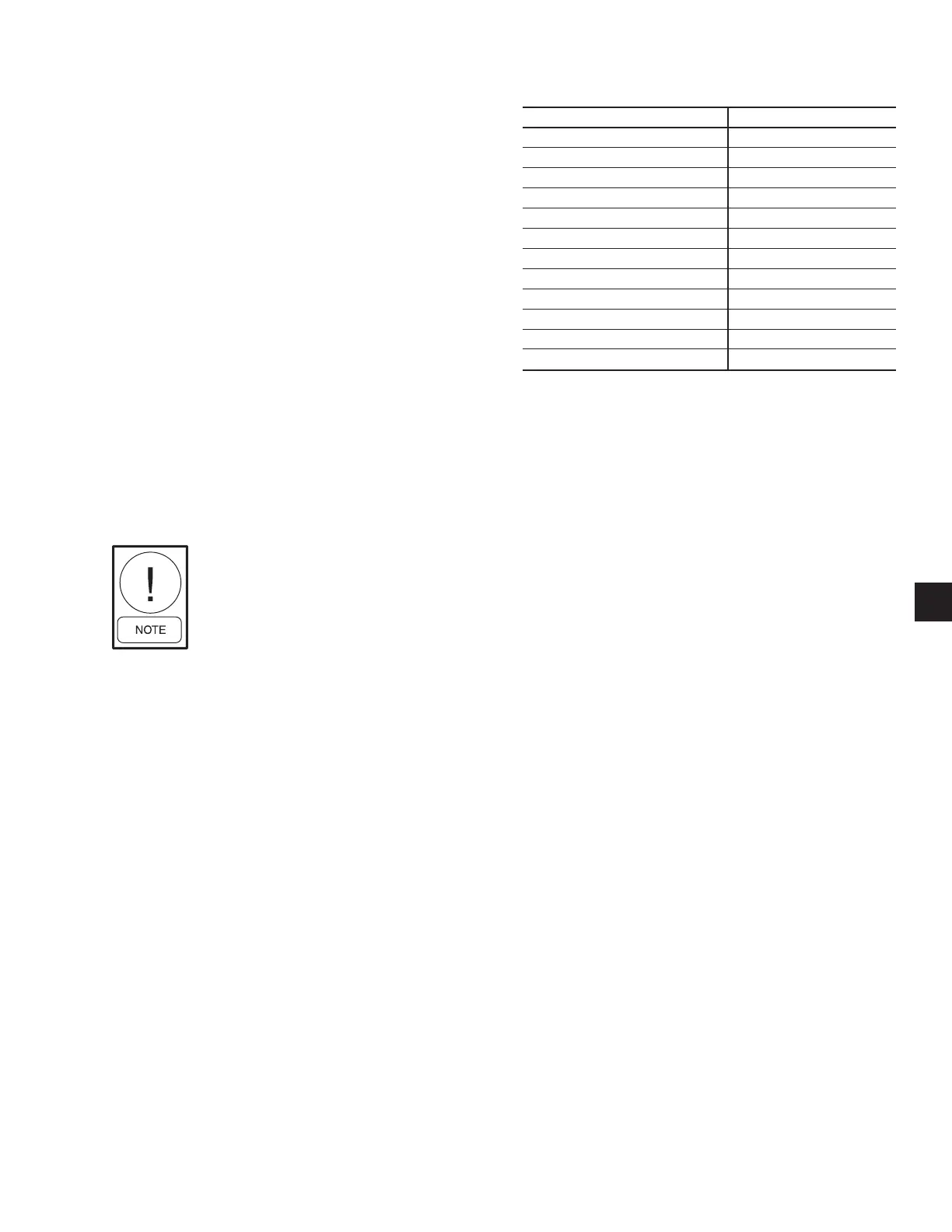

TABLE 39 – KEYPAD PIN ASSIGNMENT MATRIX

KEYPAD PIN CONNECTIONS

STATUS 1 TO 5

OPER DATA 1 TO 7

PRINT 1 TO 6

HISTORY 1 TO 8

UP ARROW 2 TO 5

DOWN ARROW 2 TO 7

ENTER/ADV 2 TO 6

COOLING SETPOINTS 2 TO 8

SCHEDULE/ADVANCE DAY 3 TO 5

PROGRAM 3 TO 7

OPTIONS 3 TO 6

CLOCK 3 TO 8

3

KEYPAD

The operator keypad is connected to the microboard

by a ribbon cable, which is connected to J2 on the mi-

croboard.

The integrity of a specic “button” on the keypad can be

veried by doing a continuity check across two specic

points (or pins), that represent one of twelve “buttons”

on the keypad.

Table 39 lists the key/pin assignments for the keypad.

Power to the microboard must be turned off, and

the ribbon cable disconnected from the microboard

prior to conducting the tests, or component damage

may result.

After the ribbon cable is disconnected from microboard,

ohmmeter leads are connected to the pins representing

the specic “button” to be tested. After connecting the

meter leads, the “button” being checked is pressed

and a reading of zero ohms should be observed. After

releasing the “button,” the resistance value should be

innite (open circuit).

Pin 1 is usually identied by a stripe

on the ribbon cable.

Loading...

Loading...