−8 −

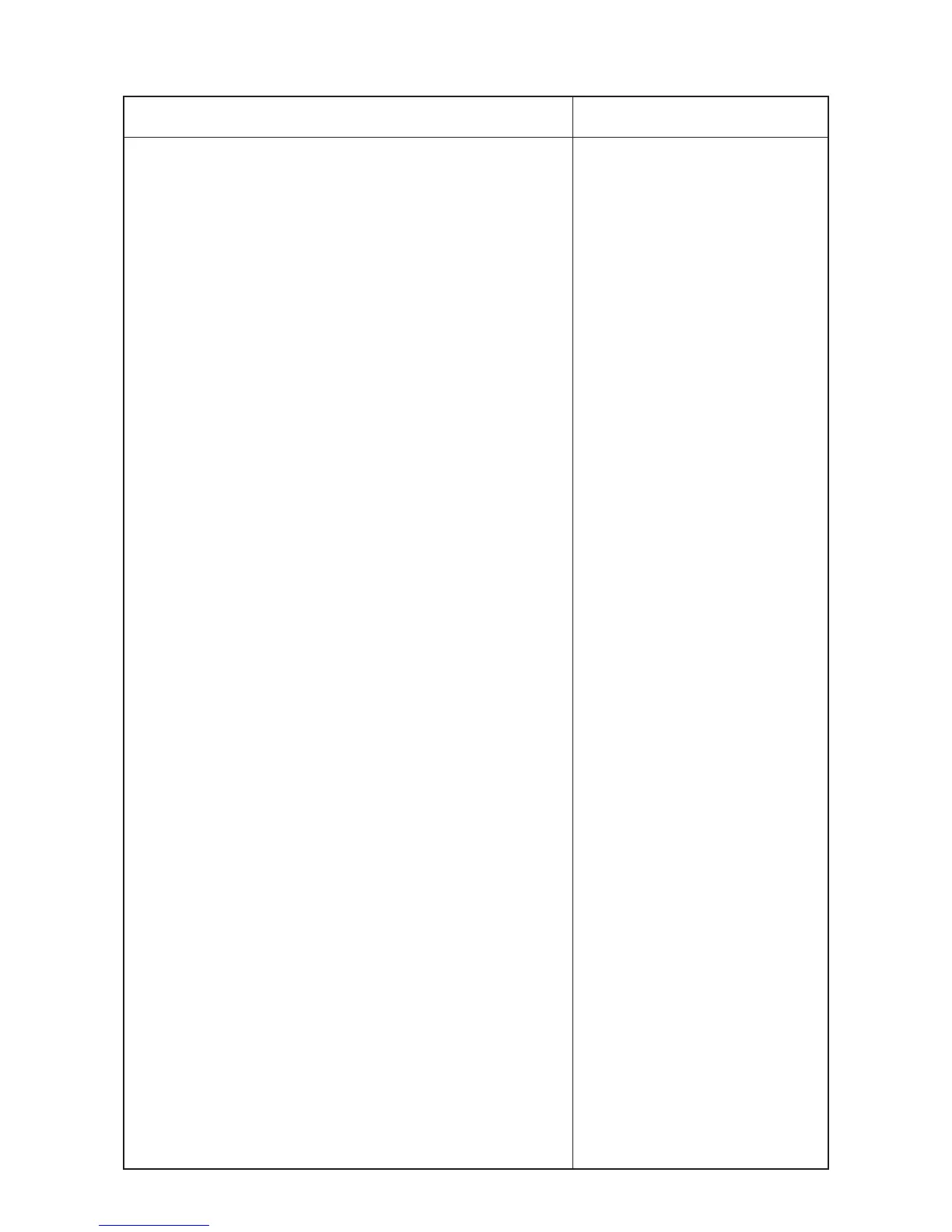

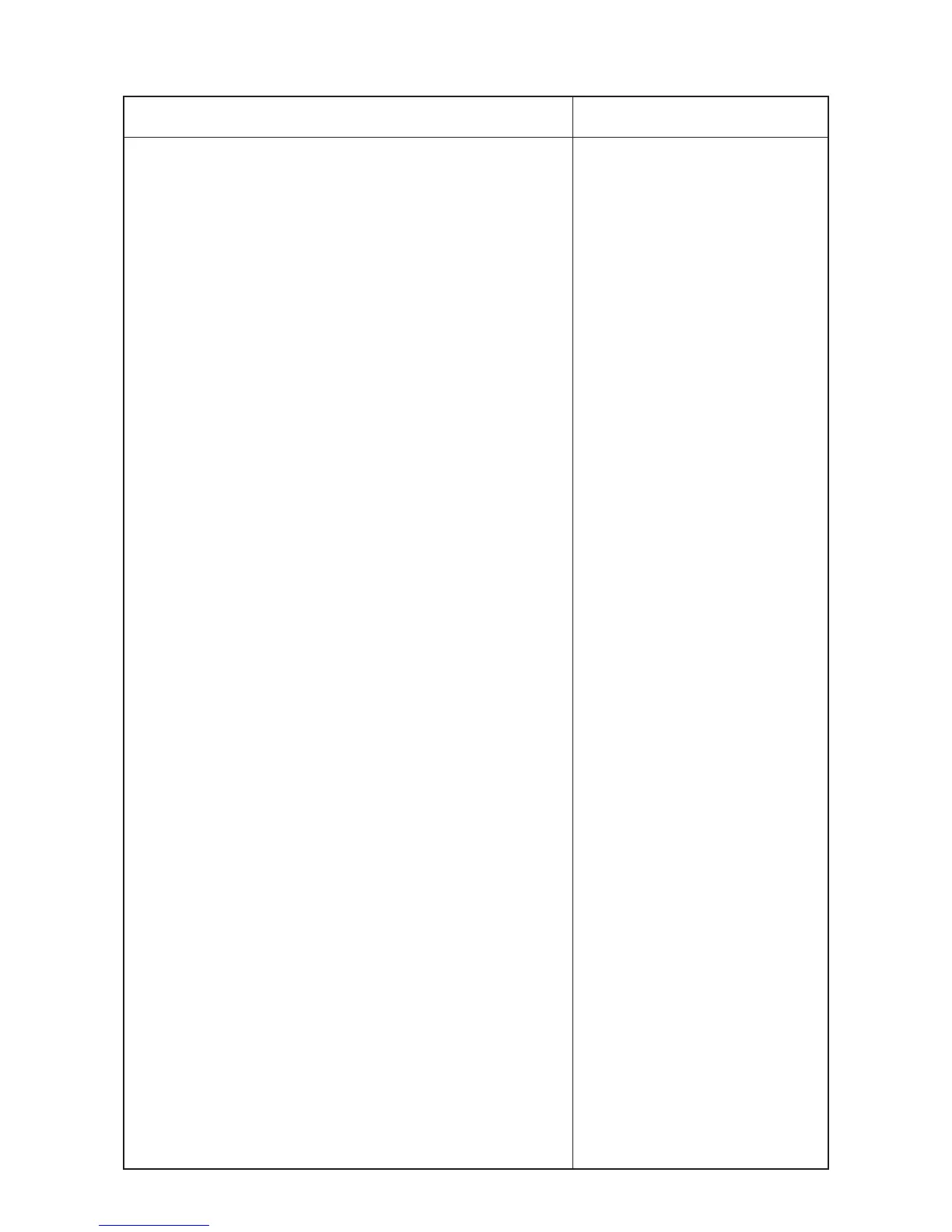

Adjustment Procedures Results of Improper Adjustment

1. Adjust the timing of feed rock triangle cam 1 to the position

where the feed dog does not move even moving the reverse

feed lever up or down when the 4th engraved marker line

(lowest marker line) is aligned with the bottom end of the metal

when the needle bar comes down.

2. Loosen two setscrews 2 in feed rock triangle cam 1.

3. Turn the handwheel with feed rock triangle cam 3 fixed in the

normal rotational direction to retard the feed timing, or in the

reverse direction to advance the feed timing.

4. Install feed rock triangle cam 3 so that the edge of feed rock

rod 3 comes in contact with feed eccentric cam side plate 4

of feed rock triangle cam 1.

(Caution) Turn the main shaft and check that there is no skew

between feed rock rod 3 and feed eccentric cam

side plate 4.

5. To adjust the timing of feed driving cam 5, stop the cam at the

position where the top surface of the feed dog is aligned with

the top surface of the throat plate when the top end of needle

eyelet of the sewing needle is aligned with the top surface of

the throat plate while the needle bar descends. (Alignment of

three points)

6. Loosen two setscrews 6 in feed driving cam 5.

7. Turn the handwheel with feed driving cam 5 fixed in the normal

rotational direction to retard the timing of the vertical movement,

or in the reverse direction to advance the timing.

™ When loop is not tightened in

overlapped section sewing,

retard the feed timing. Then feed

tightening is applied and loop is

tightened.

™ If the timing is excessively

advanced or retarded, the

sewing product is fed when the

needle is pierced. As a result,

needle breakage, bend of

spreader, etc. will occur.

™ When the timing between feed

rock triangle cam 1 and feed

driving cam 5 is not proper,

return is applied to the feed dog

at the end of feed or at the start

of feed. As a result, stitch

skipping will be caused.

Loading...

Loading...