−28 −

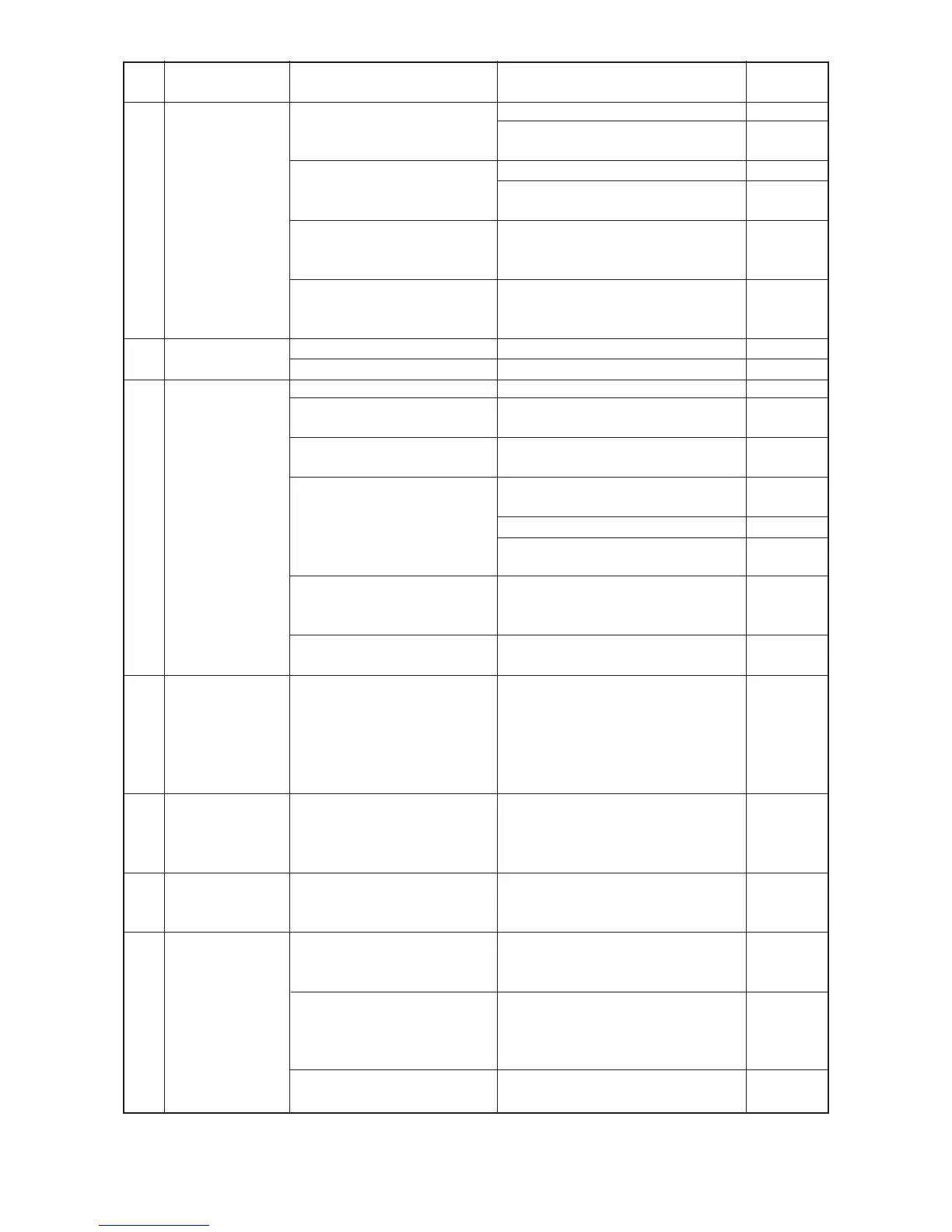

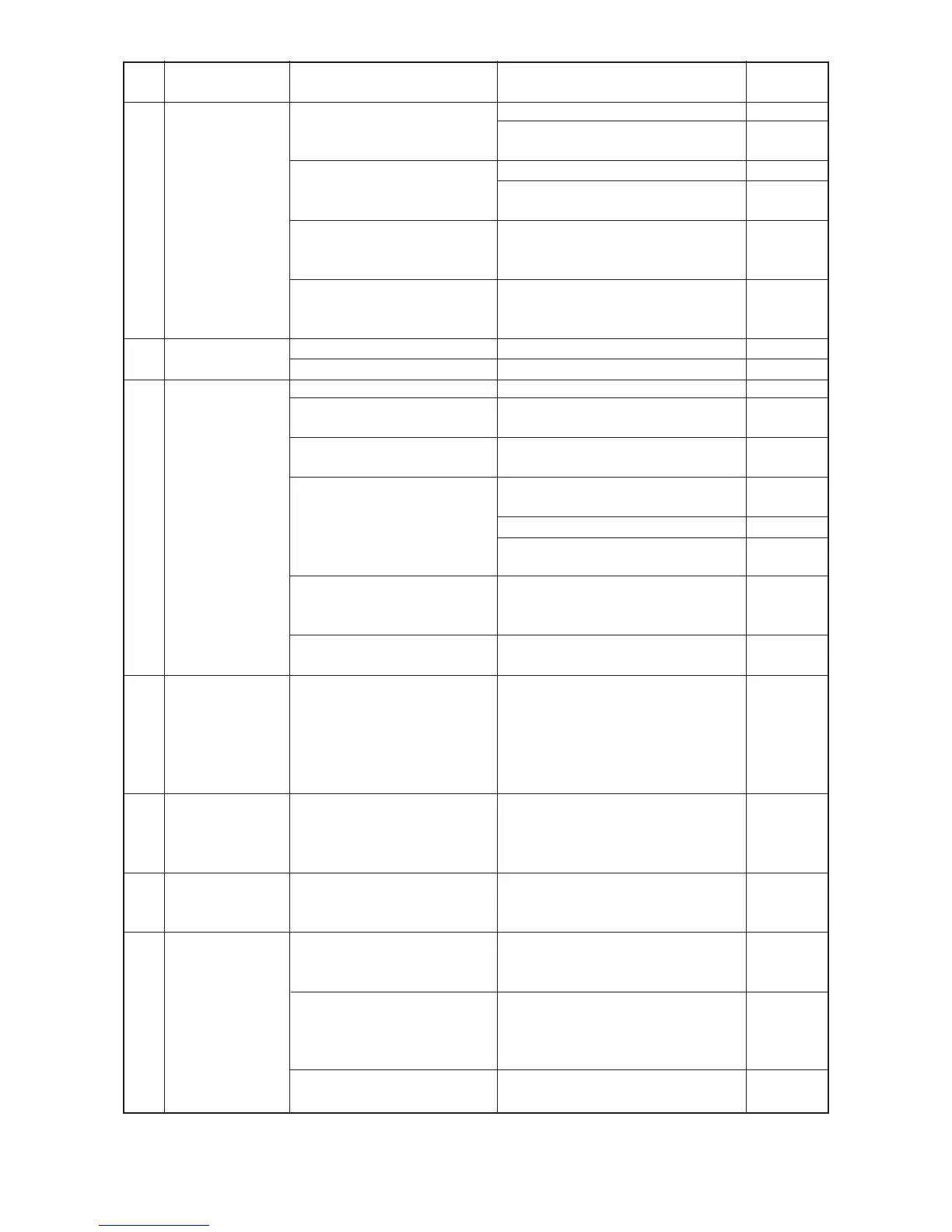

4.

5.

6.

7.

8.

9.

10.

Corresponding

page

P. 19

P. 19

P. 19

P. 11

P. 15

P. 5

P. 5

P. 5

P. 7

Thread tension

defect

Fabric yarn

breakage (run)

Chain-off thread

does not come out.

General sewing

defect (In case of

spun thread or the

like)

Fabric yarn

breakage occurs

with synthetic knit

goods.

Thread pulling

occurs with light-

weight materials.

Breakage or wear

of spreader

Loop on the right side of cloth is

too large.

Loop is excessively tightened.

Stitches on the right side of

sewing product (wrong side when

sewing) are strongly tightened.

When the presser is raised in the

corner stitching, thread is

loosened.

Thread tension is too high.

Hook needle has burrs.

Loop guide fails to work.

Needle does not enter until it goes

to the end.

Timing between spreader and

looper is not proper.

Thread fails to enter loop due to

rough motion of thread at the time

of chain-off thread.

Chain-off thread is difficult to

come out due to cloth pulling

condition.

Thread is thick and chain-off

thread is caught on feed dog.

When using the thread of large

resistance such as spun thread or

the like, if there are many

threading sections such as thread

guide and the like, change of

thread tension increases.

Needle is too thick.

Needle is too thick.

Machine turns a sharp curve by

force.

Machine is sewing an extra

heavy-weight material.

Contact of parts

Increase the thread tension.

Move to upside the thread take-up thread

guide, right.

Reduce the thread tension.

Move to downside the thread take-up

thread guide, right.

Move to downside the thread take-up

thread guide, left.

Increase the rising timing of thread

tension disk.

Adjust the thread tension.

Replace the needle with a new one.

Bring up the loop guide near the needle.

Enter the needle until it goes to the end.

Readjust the timing.

Reduce the stroke of the thread take-up

spring.

Decrease the height of the feed dog.

Reduce the vertical movement of the feed

dog.

Lightly pull the cloth backward in the left

direction.

Increase the vertical movement of the

feed dog.

Reduce to the utmost the threading

sections between thread stand,

intermedite thread guide and arm thread

guide, and reduce the change of thread

tension.

Use a thin needle within the sewing

possible range.

Use a thin needle within the sewing

possible range.

Turn the curve slowly.

Do not change the direction when needle

is pierced.

Advance the feed timing and make the

needle pierce the sewing product after

the sewing product has been completely

fed.

Check whether the parts come in contact

with each other.

Corrective measuresCausesTroublesNo.

Loading...

Loading...