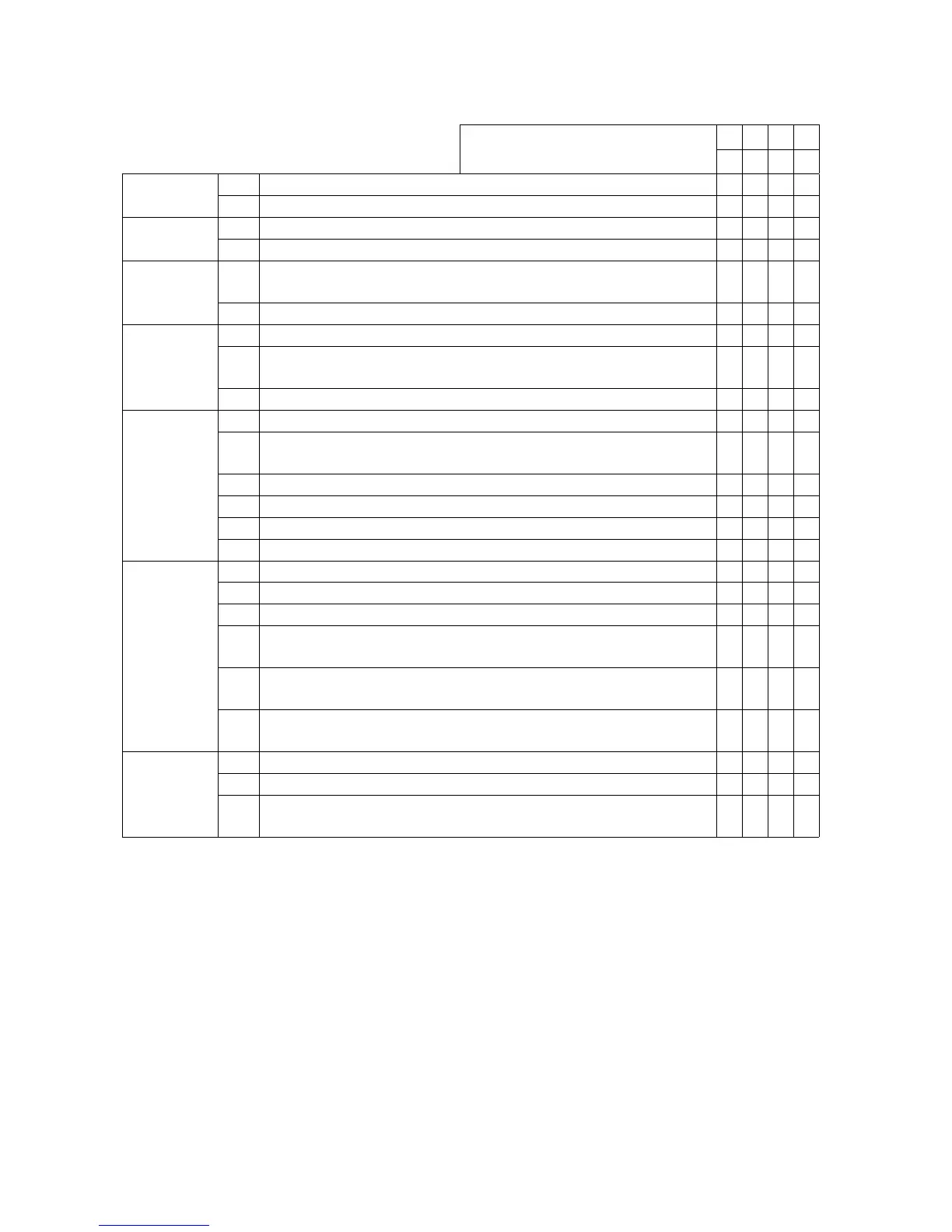

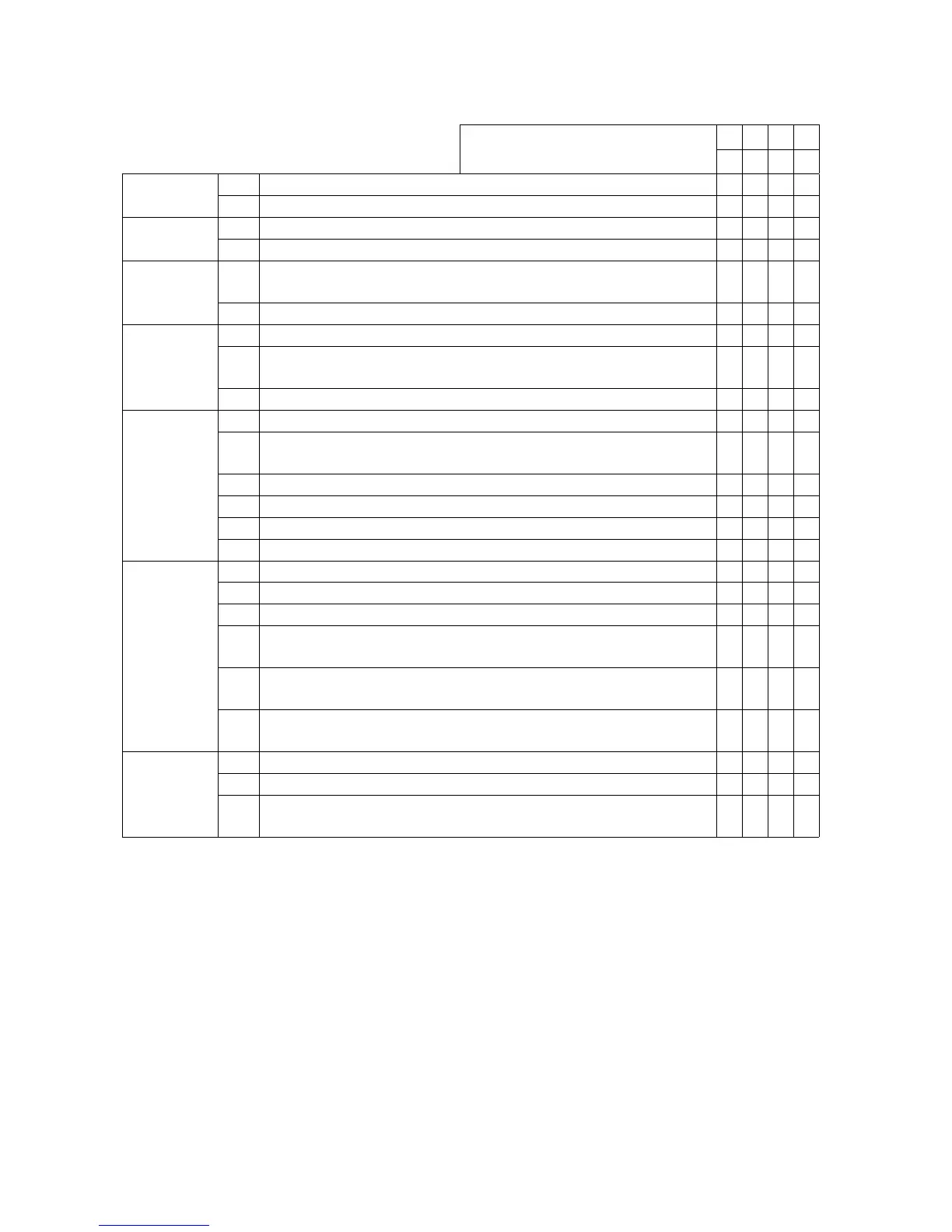

0307.USA

G 8

4 Maintenance checklist

Maintenance intervals

Standard = t WABC

Refrigerated warehouse = k

Frame/

structure:

1.1 Check all load-bearing elements for damage t

1.2 Check bolted joints t

Drive: 2.1 Check gearbox for noises and leaks t

2.2 Check gearbox oil level t

Wheels: 3.1 Check for wear and damage, adjust fork base height and

fork tip height if necessary

t

3.2 Check bearings and mounting kt

Brake

system:

5.1 Check function and settings kt

5.2 Check tiller spring for reset function,

leaks and damage

t

5.3 Check wear on brake linings t

Hydraul.

system:

6.1 Check function kt

6.2 Check joints and connections for leaks

and damage

kt

6.3 Check hydraulic cylinder for leaks, damage and mounting kt

6.4 Check oil level kt

6.5 Change hydraulic oil kt

6.6 Check function of pressure relief valves kt

Electrical

system:

7.1 Check function t

7.2 Check cables for damage and for tight fit of connections t

7.3 Check fuses for correct value t

7.4 Check function of switches and switch cams and check for

tight fit

t

7.5 Check contactors and relays, replace

wear parts if necessary

t

7.6 Check function of warning devices and

protective circuits

kt

Electric

motors:

8.1 Check wear on carbon brushes (lifting motor) t

8.2 Check motor mounting t

8.3 Vacuum out motor housing, check

commutator for wear (lifting motor)

kt

Loading...

Loading...