40 English

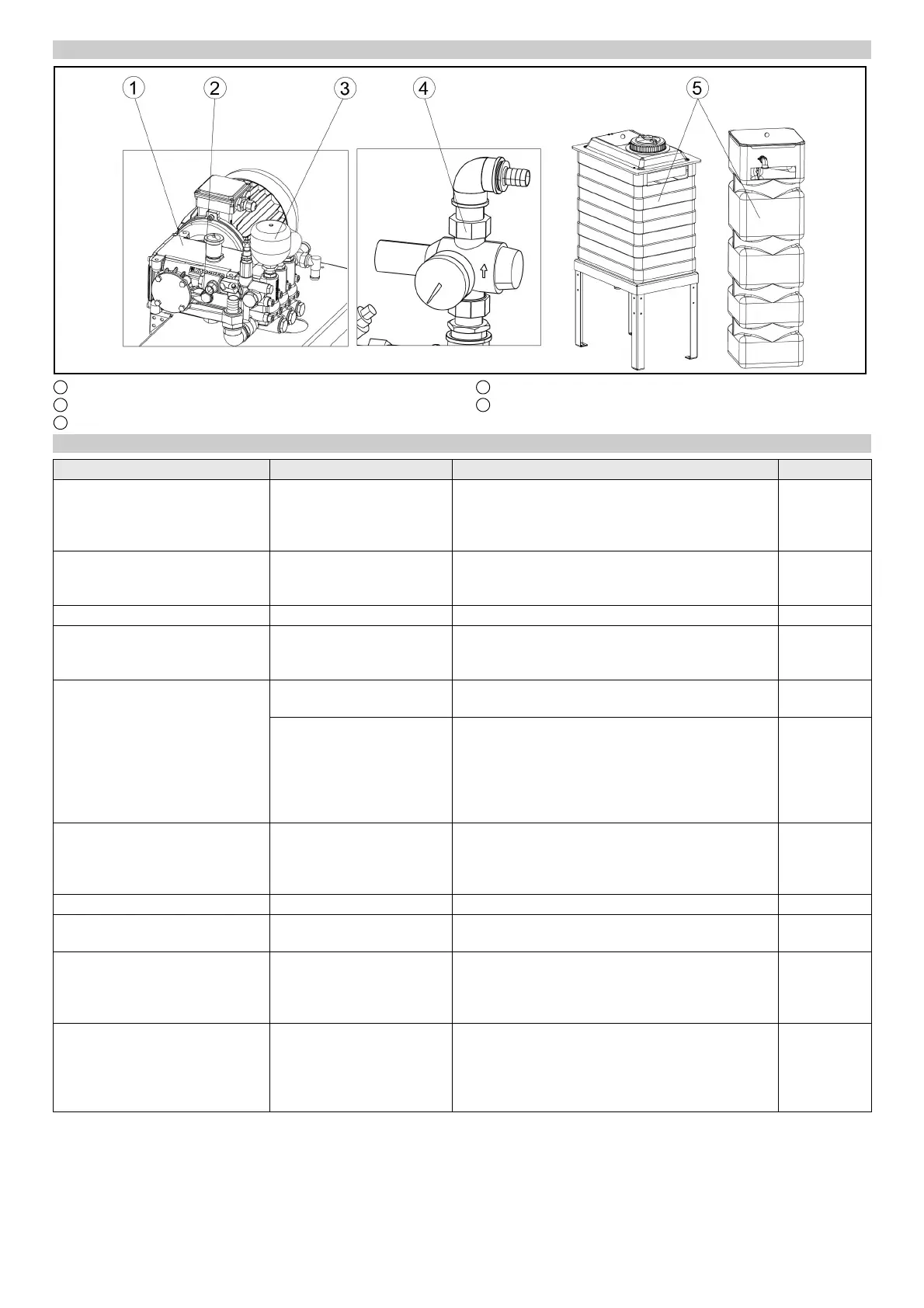

Machine room maintenance overview

1 High-pressure pump

2 Oil level indicator

3 Pressure tank

4 Pressure reducer

5 Fresh water tank

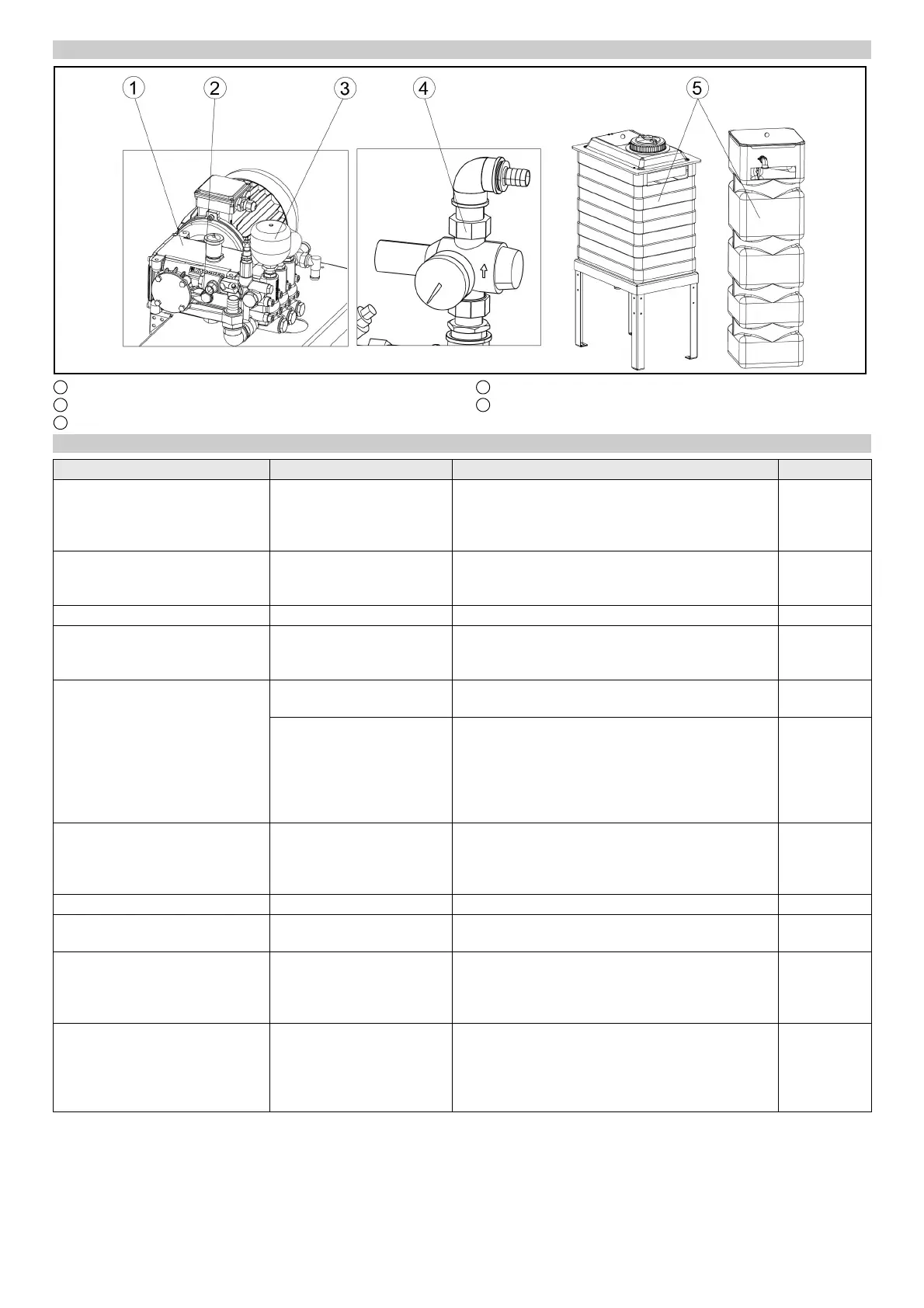

Daily maintenance plan

Assembly Activity Performed Target group

Emergency off button

Safety switch

Check Start the washing program, actuate an emergency-off

button or safety switch, the system must stop imme-

diately, then switch the system on again, see chapter

“Switching on again after an emergency off”.

Operator

Signs with operating instructions

and intended use

Check the instructions for

self-service customers (self-

service systems only)

Check all signs for completeness and legibility.

Replace any damaged signs.

Operator

Cleaning and care agent reservoirs Check the filling level Refill or replace as necessary. Operator

High-pressure hoses from the

high-pressure pump to the wash-

ing bay

Check Check the hoses for damage. Replace faulty hoses

immediately. Danger of accident.

Operator

Spray nozzles/sieves Checking for clogging Visual inspection (assess the spray pattern), clean if

necessary.

Operator

Eliminate clogging Warning, do not swap over the nozzles.

Unscrew nozzles individually to avoid mixing them

up.

Clean with compressed air or insert in a detergent

solution and then clean with a brush or needle. Screw

in the nozzles again.

Operator

Light sensors Check for soiling, clean if

necessary

For light soiling, wipe the light sensors with a damp

cloth without detergent under light pressure. In the

event of heavy soiling, spray the cloth with a gentle

detergent.

Operator

Limits switches Visual inspection Check for mechanical damage and firm seating. Operator

Side brushes, roof brush, wheel

brushes

Check for foreign bodies Visual inspection, remove any foreign bodies, clean

dirty brushes with a high-pressure cleaner.

Operator

Rinsing and spray circuits Check the water supply In washing mode, check that sufficient water for vehi-

cle washing is available.

Too little water of no water can damage the vehicle

being washed.

Operator

Positioning light Function test Interrupt the “Position 1” and “Position 2” light sen-

sors, for the position of the light sensors see chapter

“Front maintenance overview”.

The positioning light must display corresponding sig-

nals.

Operator

Loading...

Loading...