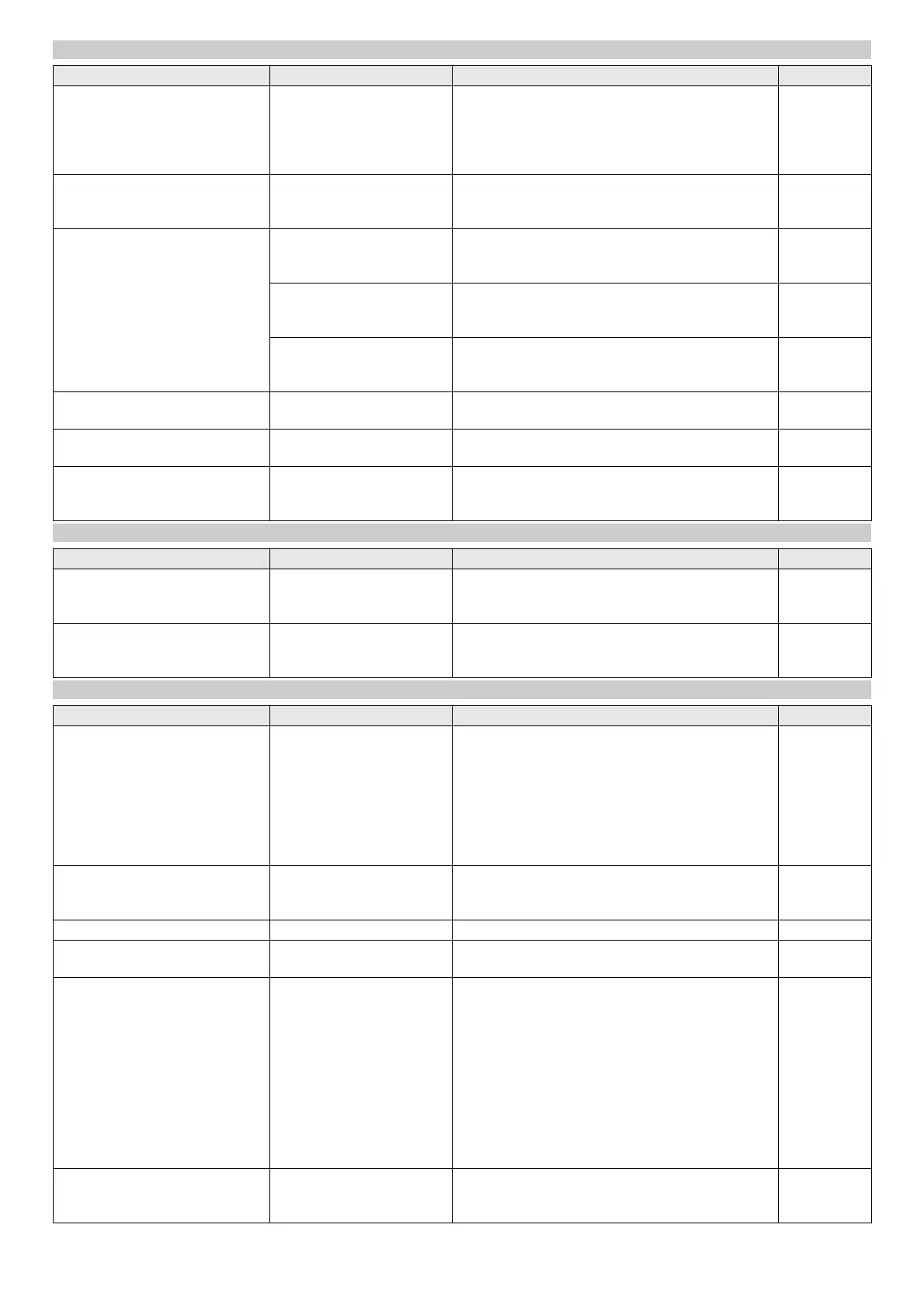

English 41

Weekly maintenance plan or after 500 vehicle washing hours

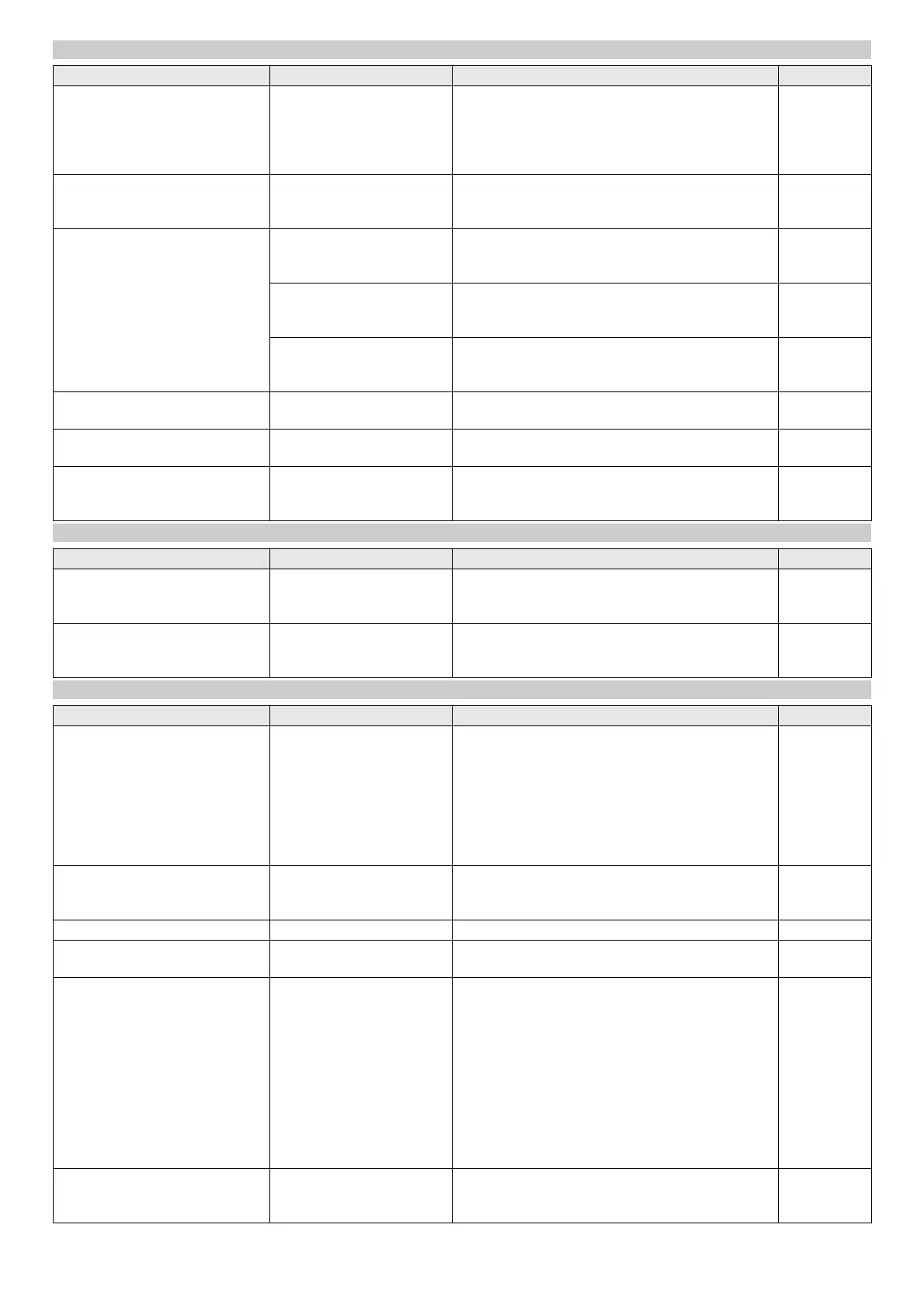

Maintenance plan after 1000 washes

Monthly maintenance plan after 2000 washes

Assembly Activity Rectification Target group

Roof brush rollers

Side brush rollers

Visual inspection Check the true running of the brush shaft.

Check the brushes for tight seating.

Check the brush for wear and tear.

Minimum bristle length = as-new length minus 50 mm

Replace the brushes if necessary.

Operator

Supply line hoses and pipeline Visual inspection Check for leaks. Operator

Customer Ser-

vice

High-pressure pump(s) Checking for leaks Check pump and line system for leaks. Notify Cus-

tomer Service if you lose oil or if there is a leak of

more than 10 drops of water per minute.

Operator

Checking the oil level Target level in the middle of the oil level indicator. Top

up with oil if necessary (order no. 6.288-020.0) and

inform Customer Service immediately.

Operator

Check pressure tank If there is increased vibration in the high-pressure

pump, the pressure tank is defective. Contact Cus-

tomer Service.

Operator

Customer Ser-

vice

Fresh water tank Check the float switch Check the function of the float valve (see "Mainte-

nance work").

Operator

Operating station with display Cleaning/Care Wipe the surface with a damp cloth, spray the cloth

with a detergent and clean it if heavily soiled

Operator

Panel/glass front system Cleaning Spray the surface with an acidic cleaner and clean

with a soft pad, then rinse with clean water and re-

move with a squeegee

Operator

Assembly Activity Performed Target group

Check the running rollers of the

side brush rollers

Visual inspection Check the play by moving the side brushes.

Contact Customer Service in the case of excessive

play between the carriage and guide.

Operator

Customer Ser-

vice

Screws on the guide rails for the

roof brush and roof drier

Re-tighten Check for tight seating of the screws and tighten if

necessary.

Tightening torque 25 Nm

Operator

Customer Ser-

vice

Assembly Activity Rectification Target group

Maintenance unit Cleaning the filter Shut off the compressed air supply and then extend

and retract the wheel washing unit in manual mode

until the system is depressurised.

Check the pressure gauge to ensure that the system

is completely depressurised.

Unscrew the filter housing, remove the filter insert,

clean the filter with compressed air, fit the filter, screw

the cover on again.

Operator

Processed water and fresh water

dirt trap

Cleaning Shut off the water supply, unscrew the cover of the

dirt trap, remove the filter, flush the filter with water, fit

the filter again, screw on the cover.

Operator

Pressure reducer Cleaning the sieve See "Maintenance work". Operator

Roof brush and roof drier Visual inspection of the drive

belts

Check the condition of the drive belts and replace if

necessary.

Customer Ser-

vice

All limit switches Check the fasteners and

clearances4

Check the clearance between the limit switch and

switching vane using a feeler gauge.

If necessary, adjust the limit switches by adjusting the

plastic nuts.

Limit switch clearances:

● Ø30 mm = 5.0 mm

● Ø30 mm = 2.0 mm

● Side brush movement counter

Ø12 mm = 3.0/ ±0.1 mm

● Roof brush/drier lifting counter

Ø12 mm = 3.5/ ±0.1 mm

Customer Ser-

vice

Washing hall Cleaning Spray the surfaces such as floor, walls and tiles with

an acidic detergent, allow to take effect, clean off the

detergent with a soft pad (white)

Operator

Loading...

Loading...