44 English

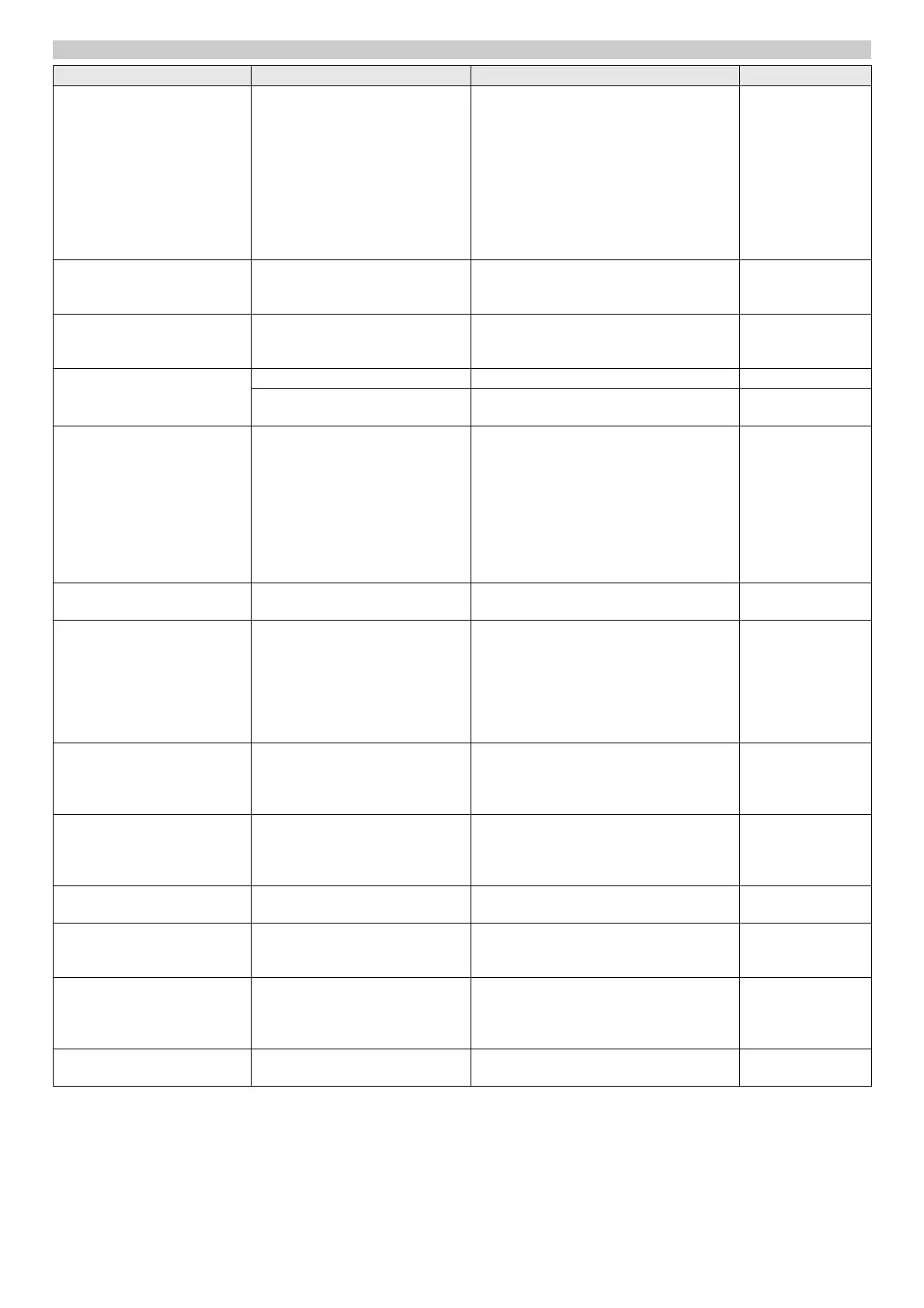

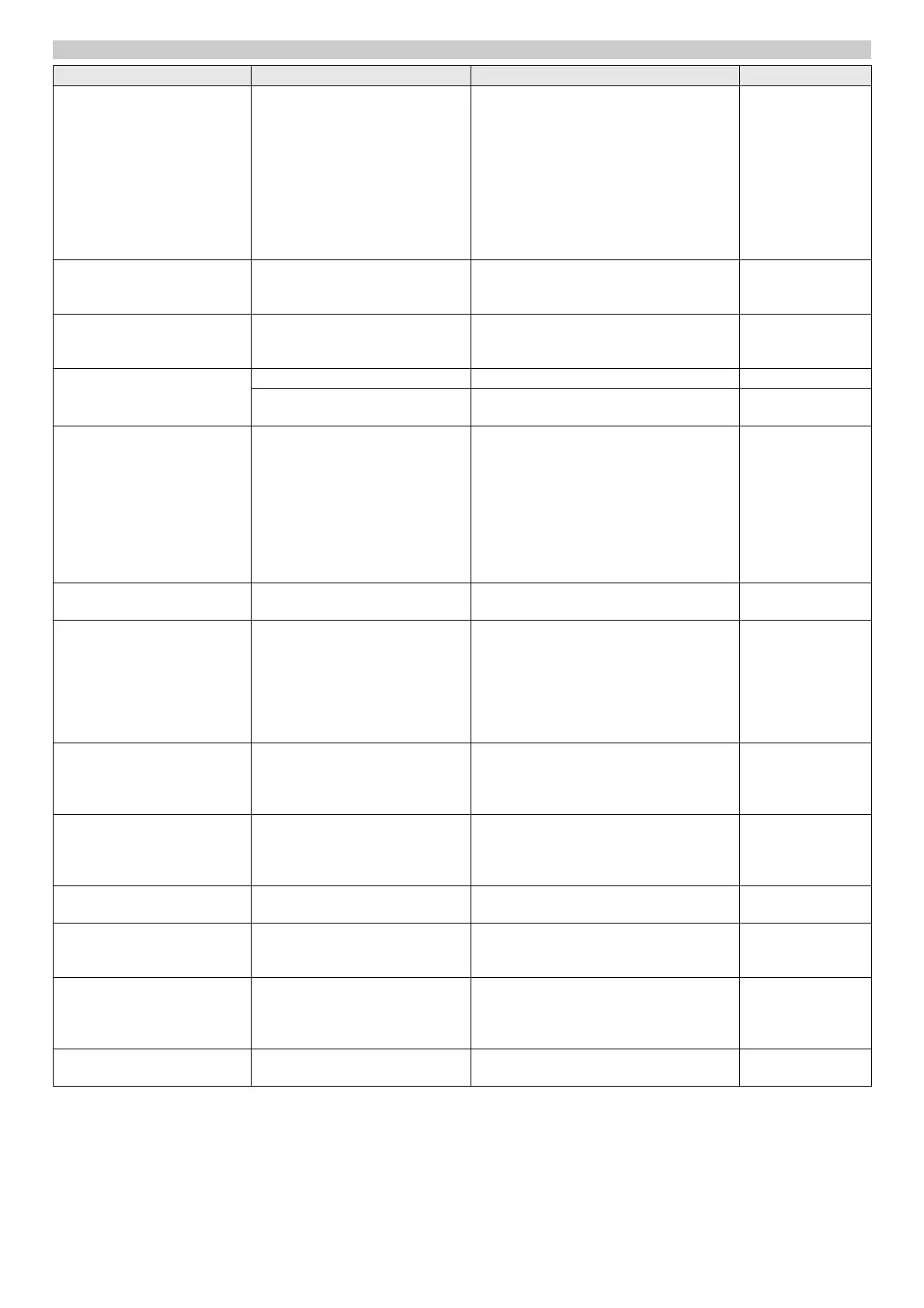

Faults that are not displayed

Fault Cause Rectification Person responsible

Inadequate cleaning efficien-

cy

No cleaning agent or insufficient

cleaning agent

No air pressure or insufficient air

pressure in the supply line

Worn brushes

Check the cleaning agent filling level and

refill if necessary, vent the dosing pump.

Check the air pressure and adjust if nec-

essary (0.6 MPa (6 bar) at the mainte-

nance unit pressure gauge).

Clean the cleaning agent intake filter,

check the cleaning agent pipes for dam-

age.

Check the brushes and replace if neces-

sary.

Operator

High-pressure pump does

not reach pressure

Suction-side pipeline system leak-

ing.

Water shortage

Check the screw connections and hos-

es.

Eliminate water shortage.

Operator, Customer

Service

The pressure gauge pointer

of the high-pressure pump vi-

brates strongly

Pump sucking air

Pressure tank defective

Check suction line.

Replace pressure tank.

Customer Service

The high-pressure pump

safety valve opens

Clogged washing bay nozzles Check, clean, replace nozzles. Operator

Hose or high-pressure valves

clogged

Remove clog. Customer Service

Too little water or no water

coming out of the nozzles

Dirt trap clogged

Insufficient water pressure

Nozzle clogged

Air in the centrifugal pump

Solenoid valve or supply line

clogged

Clean the dirt trap

Check the water supply pressure and

pumps

Clean the nozzles with compressed air

Venting the centrifugal pump by loosen-

ing the bleed screw

Check the solenoid valves and supply

lines (water and electricity) and repair if

necessary

Operator

Water continues coming out

of the nozzles after washing

Dirty solenoid valve Clean the solenoid valves Customer Service

Inadequate drying Too little or too much drying aid

Incorrect drying aid

No air pressure or inadequate air

pressure

Increase or reduce the dosage

Check the cleaning agent filling level

Clean the intake filter

Vent the dosing pump

Use original drying aid from Kärcher

Check that the drying blower is working

correctly

Operator

The wheel washing brush

does not rotate

T

he motor circuit breaker in the

control cabinet has triggered

Contact pressure too high

Check the motor circuit breaker in the

control cabinet

Reduce the contact pressure at the

wheel wash pressure reducer

Operator

The wheel washing brush ex-

tends slowly or not at all

No air pressure or inadequate air

pressure

Check the air pressure and adjust if nec-

essary

Increase the contact pressure at the

wheel wash pressure reducer

Operator, Customer

Service

The wheel washing brush ex-

tends at the wrong position

Dirty light sensors Clean the light sensors and check the

settings if necessary

Operator

The brushes become dirty

quickly

Shampoo dosage too low Adjust the shampoo dosage

Check the water volume and adjust if

necessary

Operator

The undercarriage wash noz-

zle pipes pivot too slowly/too

quickly or not at all

No air pressure or inadequate air

pressure

Pivoting unit heavily soiled

Chokes incorrectly adjusted

Check the air pressure in the supply line

and adjust if necessary

Clean the pivoting unit

Re-adjust the chokes

Operator, Customer

Service

The system cannot be

switched on

Power supply fault Ensure a fault-free power supply as

specified in the connection values

Operator, qualified

electrician

Loading...

Loading...