3 – 12

MAINTENANCE

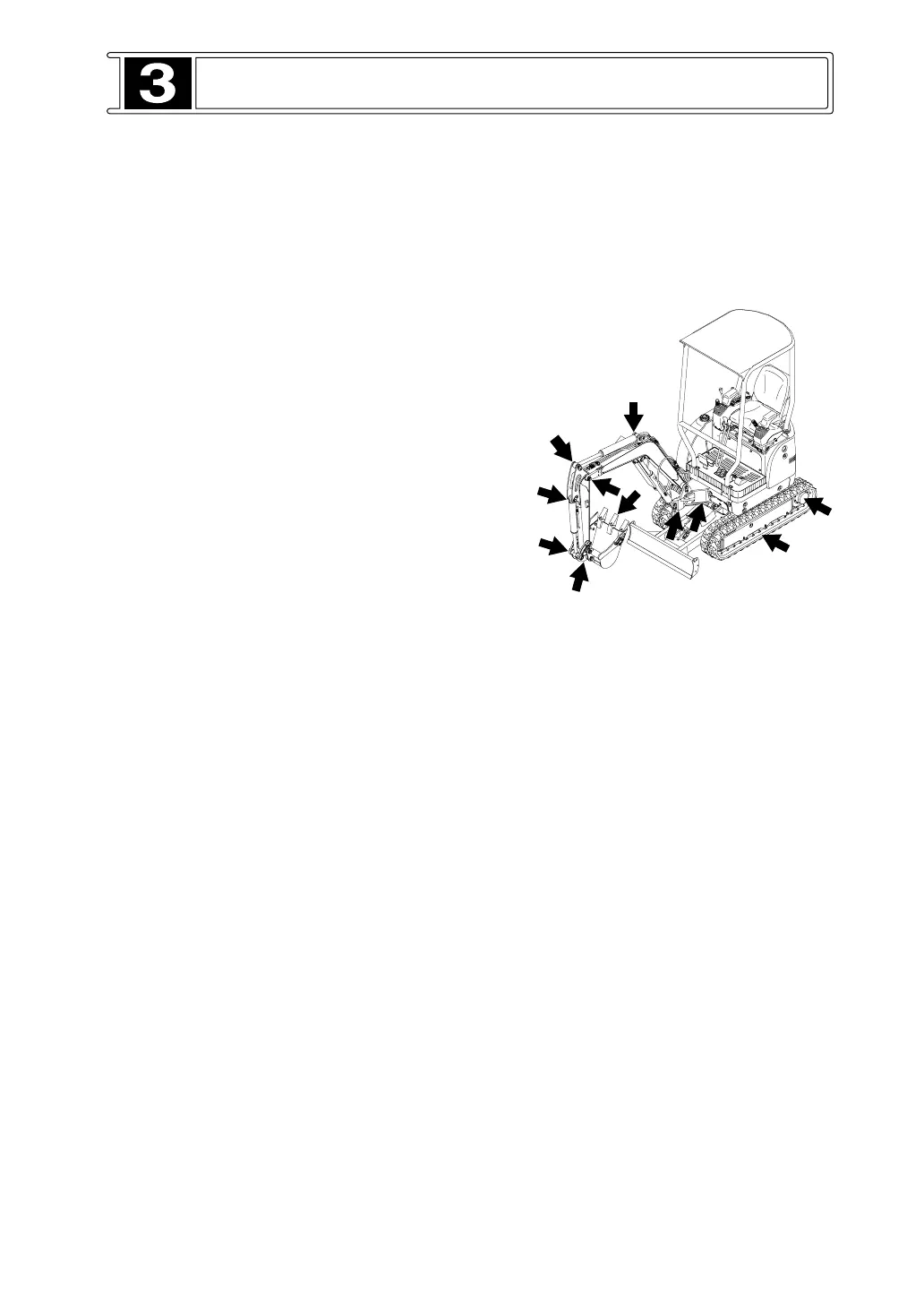

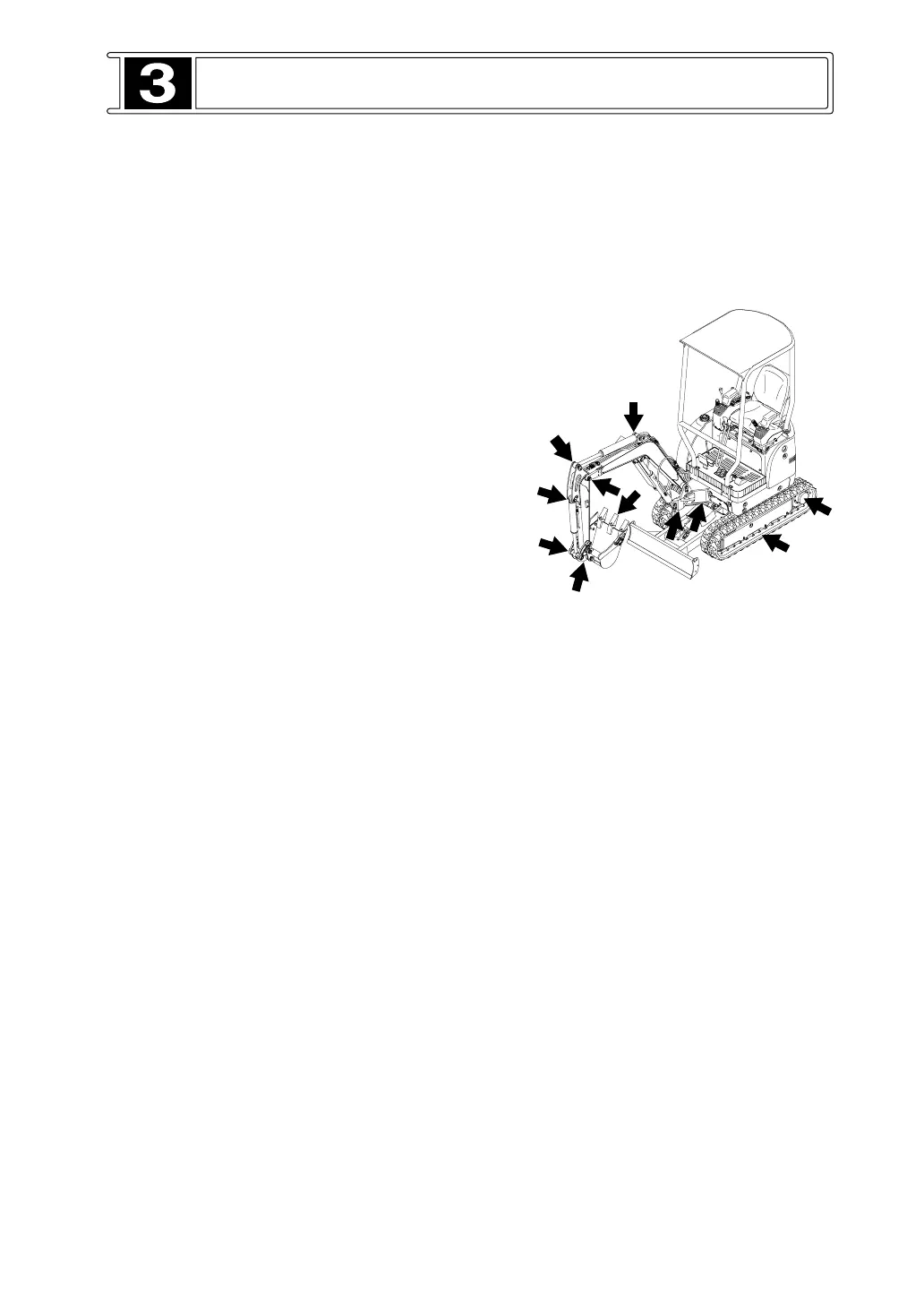

Walk-Around Inspection

Inspect the operator’s compartment for cleanliness.

Keep it clean.

Inspect the loose bolts, Tighten any loose bolts.

Repair if necessary.

Inspect any cracks in boom and arm pivot area and

cylinder mounting brackets.

Repair if damaged.

Inspect attachment cylinders, linkage and bucket

for damage or excessive wear. Rep

air if damaged.

Inspect and remove any trash build up in the engine

compartment.

Inspect the cooling system for leaks, faulty hose

and trash built up. Correct any leaks and remove

any trash from the radiator.

Inspect the hydraulic system for leaks. Inspect the

tank, cylinder rod seals. tubes, plugs, joints and

fittings. Correct any leaks.

Inspect and repair travel drive leaks. Check oil level

if leakage is noticed.

Daily Lubrication

Perform the daily lubrication as required by the

Lubrication Chart.

DAILY

Loading...

Loading...