GB - 10

3.3 Connection of Power Circuit

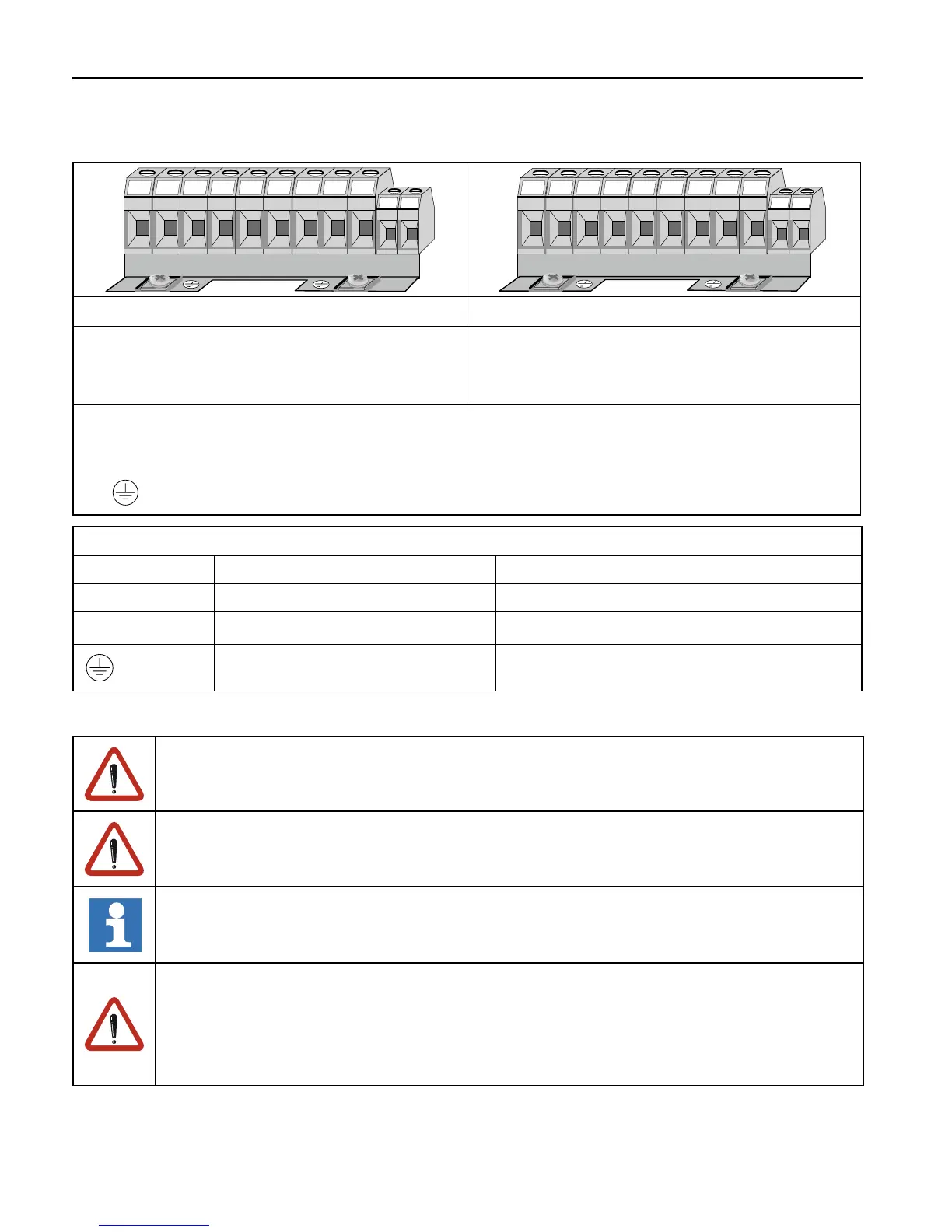

3.3.1 Terminal Strip X1A

Installation and Connection

N/L2 L3 PB U V W

T1 T2

--++

L1

L2 L3 PB U V W

T1 T2

-- ++

L1

Terminal strip X1A/ 230 V class suitable for Terminal strip X1A/ 400 V class suitable for

• 180…260 V AC / 1-phase (L1/N) • 305…528 V AC / 3-phase (L1, L2, L3)

• 180…260 V AC / 3-phase (L1, L2, L3) • DC supply 420…720 V DC (++,- -)

• DC supply 250…370 V DC (++,- -)

• ++, PB Braking resistor

• U, V, W Motor

• T1, T2 Temperature sensor / switch (see chapter 3.3.6)

•

Protective earth connection

Permissible cable cross-sections and tightening torques of the terminals

Terminals Perm. conductor cross-section Tightening torque

L1…W 0.2…6 mm² (AWG 24-10) 0.6 Nm (5 lb inches)

T1, T2

0.1…2.5 mm² (AWG 30-14)

0.6 Nm (5 lb inches)

PE Screw M4 1.3 Nm (11.5 lb inches)

3.3.2 Wiring instructions

Absolutely observe the connecting voltage of the KEB COMBIVERT. A 230V-unit will

be immediately destructed on a 400V-power supply.

Never exchange the mains and motor cables.

Some countries demand that the PE-terminal is directly connected to the terminal

box (not over the mounting plate).

Separate supply of the control

Without further cooling measure a separate supply of the control is not permissible

during a longer period, because the interior fan is not controlled here. The occuring

heat accumulation causes an accelerated aging of the capacitors and thus for a

reduction of the economic life time.

Loading...

Loading...