EN

The cable is entered into the machine through the inlet ring on the rear wall of the machine

and locked with a cable clamp (05).

The phase conductors of the cable are coupled to connectors L1, L2 and L3. The earth

protection coloured green-yellow is coupled to connector marked with earth protection

symbol

. If you are using 5-conductor cable, you must cut the zero conductor to the level of

the cable´s protective shield.

Sizes of mains cables and fuse ratings for the machine at 100% ED duty cycle are

specied in the table below:

Kempoweld 3200, 3200W

Connected voltage 230 V 400 V

Voltage range 220 – 240 V 380 – 415 V

Fuses, delayed 20 A 16 A

Connected cable 4 x 2.5 S mm² 4 x 2.5 S mm²

In cables of S type there is protective grounding conductor coloured green-yellow.

NOTE! This equipment’s electromagnetic compatibility (EMC) is designed for use in an industrial

environment. Class A equipment is not intended for use in residential location where the electrical

power is provided by the public low-voltage supply system.

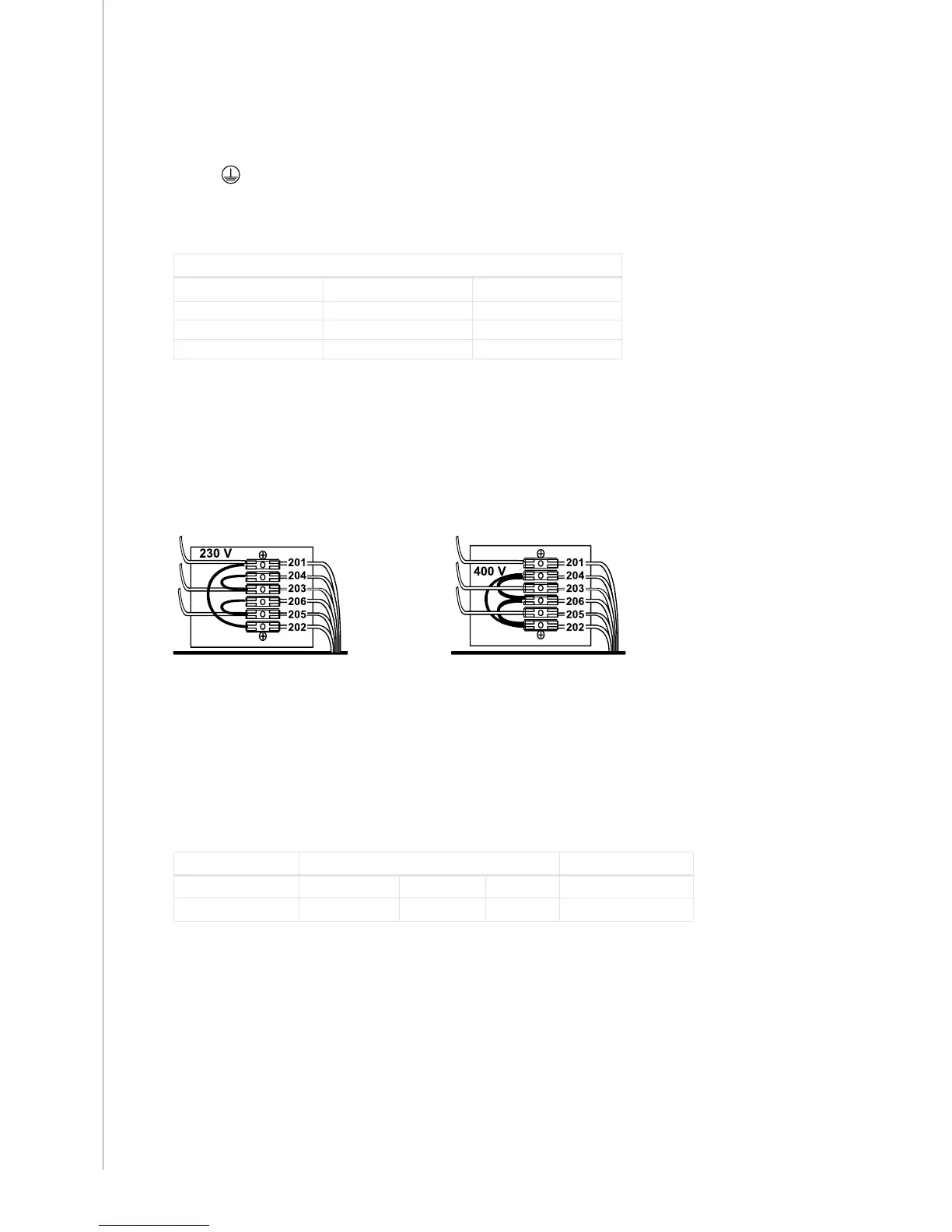

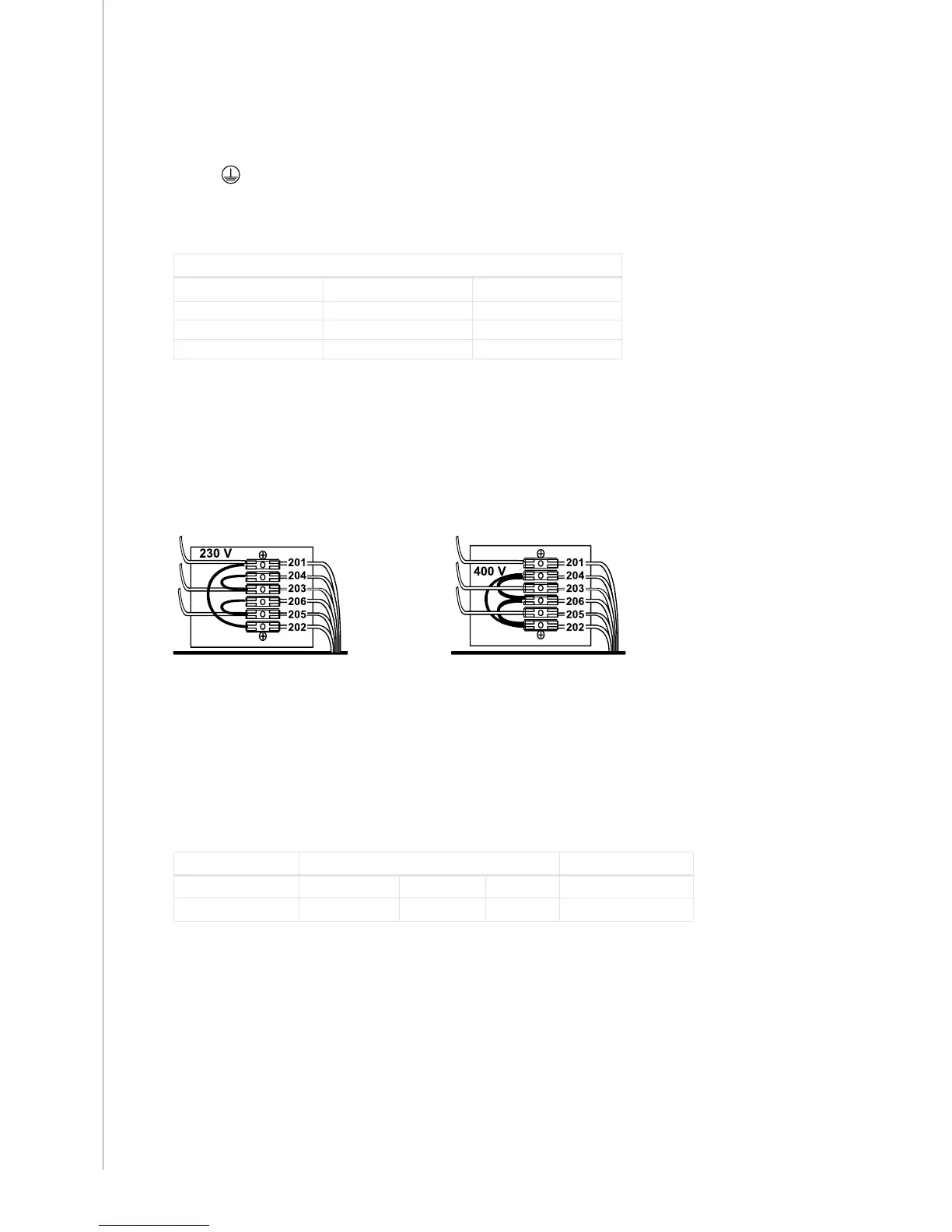

Change of mains voltage

Connection 3~ 230 or 3~ 400 V of mains voltage

By delivery from the factory the machine has been connected for mains voltage 3~ 400 V.

In order to change the mains voltage, remove the side plate of the machine. Change the

connections according to the enclosed diagram. You nd the corresponding wiring diagram

on the instruction label, which is under terminal block.

2.4 WELDING AND RETURN CURRENT CABLES

Use only copper cables with cross-sectional area of at least 50 mm². In enclosed table

are shown typical loading capacities of rubber insulated copper cables, when ambient

temperature is 25 °C and conductor temperature is 85 °C.

cable cross-section duty cycle ED voltage loss / 10 m

Cu 100 % 60 % 40 % for 100 A

50 mm² 285 A 370 A 450 A 0.35 V

Fasten the earthing press of the return current cable carefully, preferably direct onto the piece

to be welded. The contact surface area of the press should always be as large and steady as

possible.

Do not overload welding cables over permissible values due to voltage losses and heating.

Clean the contact surface from paint and rust.

8

Kempoweld 3200, 3200W / © Kemppi Oy / 1117

Loading...

Loading...