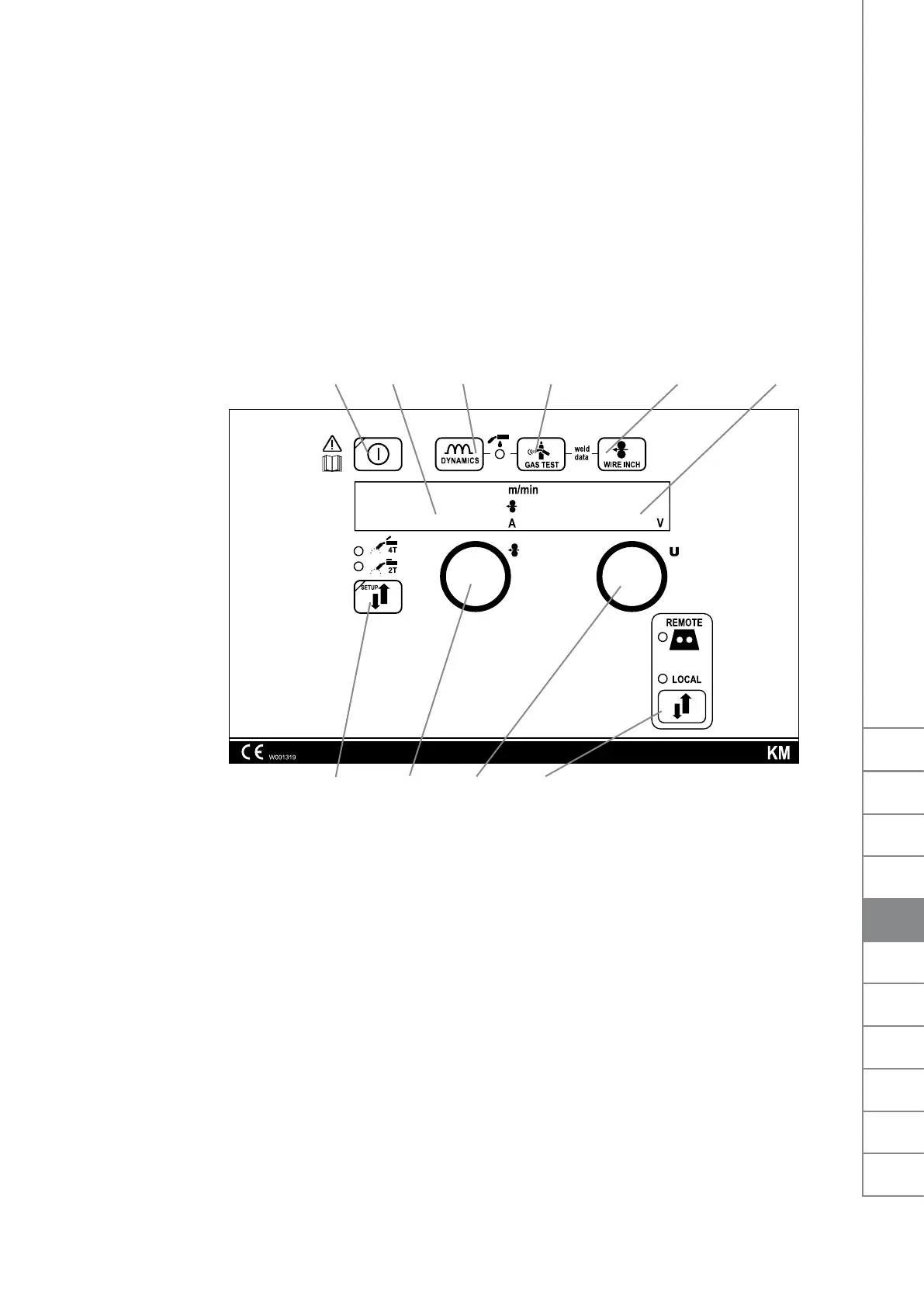

3.2 FRONT PANEL INDICATORS

Thefollowingindicatorscanbefoundonthefrontpanelofthedevice:

• Whenthegreenindicator,A3,ison,thepowersourceisinstandbymode.Thisindicator

isonwhenthemachineisconnectedtothemainssupplywiththemainswitchinthe‘I’

position.

• Whentheyellowoverheatingindicator(A4)ison,themachinehasoverheated.Thefan

then starts. When the indicator turns o, the machine can be used again.

• WhenindicatorA4blinks,themachinehasexperiencedafailure.Attempttoremedythe

problemaccordingtotheinstructionsinSection4,‘Troubleshooting’.Ifthefailurecannot

be eliminated, turn o the machine, and turn it on again. If the failure persists, write down

any fault code that may be shown on the display and contact authorised Kemppi service

agent.

P1 P2

P9P7

P3 P4 P5

P10

P6

P8

3.3 USE OF THE CONTROL PANEL

The control panel is used for controlling and monitoring the operation of the power source

and the wire feeder. The buttons are used for adjusting functions. The displays and indicators

reecttheoperatingmodesofthemachine.

3.3.1 Starting of the control panel

• Whenyoustartthepowersourcewiththemainswitch(A2),thecontrolpanelremainsin

OFFmodeandthewirefeederisnotoperational.Thedisplayshowsthetext‘OFF’.

• WhenyoudepressthestartbuttonP1foratleastonesecond,thecontrolpanelstarts.The

unit is now ready for welding and enters the mode that was active before the power was

cut o.

• Youcanalsostartthecontrolpanelbyquicklypressingtheweldinggunswitchthree

times.

3.3.2 Displays

• Whenyouareadjustingthemachinesettings,thecontrolpaneldisplaysshowadjustable

operation parameters, their values, and the units of measure.

• Duringwelding,displayP2showstheweldingcurrentvaluethatiscurrentlyinuse,while

display P6 shows the welding voltage.

EN

9

FastMig KM 300, 400, 500 / © Kemppi Oy /0901

FI

SV

NO

DA

EN

DE

NL

FR

ES

PL

RU

Loading...

Loading...