FastMig Pulse 350, 450

18

EN

WFMotorWarnLev

1.5 – 5.0 A Factory Setting: 3.5A The alarm level of wire feed motor current.

Check/service wire feed mechanism,

adjustment and gun components.

WF End Step

ON/OFF Factory Setting: OFF ON: The ller wire steps forward at the end

of the welding cycle.

OFF: Filler wire remains static at the end of

the welding cycle.

AutoWireInch

ON/OFF Factory Setting: ON Automatic SuperSnake Wire Inch feature.

When ON, the Wire Inch button drives the

ller wire automatically up to SuperSnake.

Gas Guard

ON/OFF Factory Setting: OFF Turns the gas guard on and o, provided

that one is installed.

ADMINISTRATOR MENU

Change PIN Code

Administrator pin code

change.

Factory PIN code: 0000

Ask PIN

PIN code inquiry selection:

OFF / StartUp / Menu

Factory Setting: OFF OFF: No PIN code inquiry.

StartUp: Setup panel (P65) always asks for

the PIN code when the machine is turned

on. PF 65 is not aected and always works

without PIN.

Menu: Setup panel (P65) asks every

time for PIN code when MENU button is

pressed and when the display is in channel

info mode i.e. in start-up view. PIN code

inquiry is made only once when entering

the menu. After that the menu button can

be pressed any time without PIN inquiry.

4.3.3 Welding software delivery prole

FastMig Pulse is designed to allow customer specied welding software choice. Following

delivery and installation your machine will include welding software specied at the point of

order. The tables below show typical welding programs, but there are more of them available.

Please check availability from your supplier. If the delivery specication is focused to a specic

project and you wish to update the machine in the future, you can select additional welding

software from the Wise & Match software products. Order and load these software products to

your machine with Kemppi DataGun eld program device.

Wise and Match products provide optional welding application solutions. Wise and Match

products menu includes special weld process for (1) root pass and (2) thin plate welding, (3)

auto power regulation and (4) arc length recognition, (5) minilog function, plus additional

base material welding programs and optional panel function.

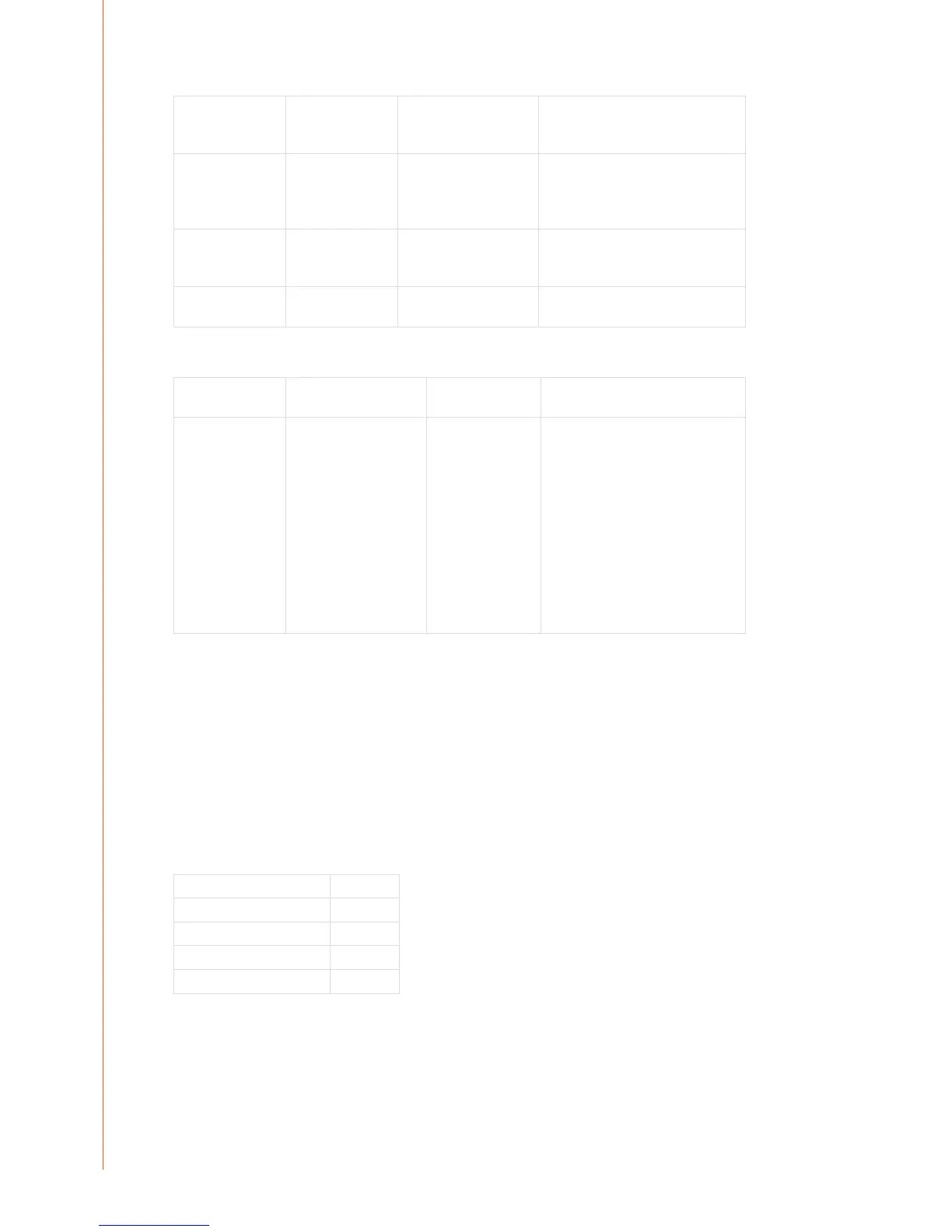

1. WiseRoot

6265011

2. WiseThin

9991013

3. WisePenetration

9991000

4. WiseFusion

9991014

5. MatchLog

9991017

Kemppi DataStore oers new welding software packages and special enhanced arc

performance solutions. Customization of FastMig Pulse systems can make welding more

ecient. Solutions oered are designed to meet the needs of wide ranging welding

environments.

You can order materials specic welding programs and/or Wise solutions separately through

Datastore or via your local supplier.

Loading...

Loading...