EN

2.4 GOUGING AND EARTHING CABLES

2.4.1 Connecting the gouging cable

The gouging cable is connected to the power source with a 120 mm

2

DIX connector. The

cable is connected either to the positive (+) or negative (-) connector of the power source,

depending on the metal that is to be worked. The power source has one negative connector

and two positive connectors. For information on the connector locations, see Introduction.

Connect the gouging cable as follows:

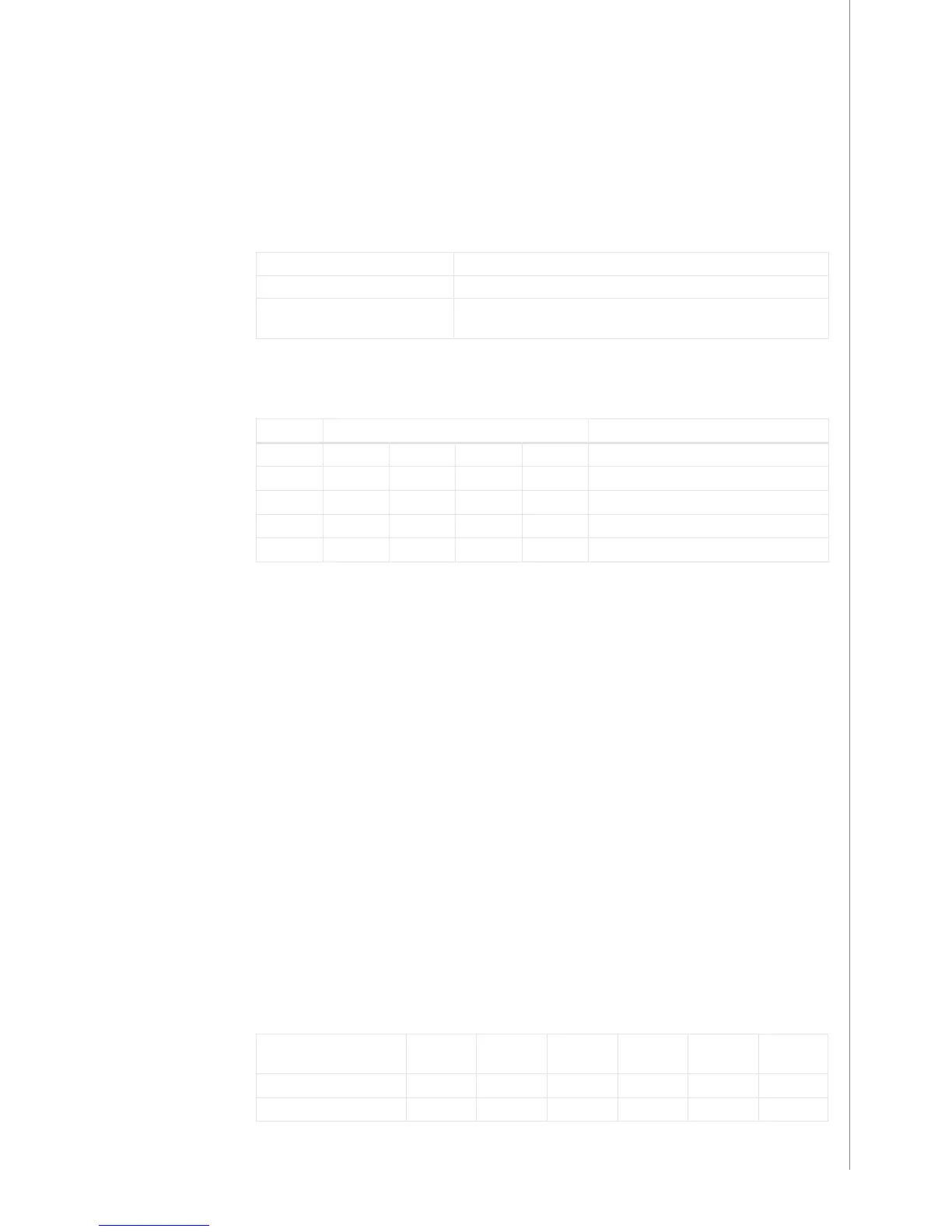

Work metal Gouging cable connection

Steel Positive (+)

Cast iron

Non-iron metal

Negative (-)

The gouging cable is rubber-insulated copper cable. The table below shows the typical load

capacities of the cables when the ambient temperature is 25 °C and the lead temperature is

85 °C.

Cable Duty cycle (ED) Voltage loss / 10 m

100 % 60 % 35 % 20 %

50 mm²

285 A 316 A 371 A 458 A 0.35 V / 100 A

70 mm²

355 A 403 A 482 A 602 A 0.25 V / 100 A

95 mm²

430 A 498 A 606 A 765 A 0.18 V / 100 A

120 mm²

500 A 587 A 721 A 917 A 0.21 V / 100 A

NOTE! Do not overload the gouging cables, as an overload may cause voltage loss and

overheating.

2.4.2 Connecting the earthing cable

The earthing cable is connected to the negative or positive connector in the power source,

depending on the connector used for the gouging cable (see Connecting the gouging cable).

The recommended cross-sections of the cable are listed in the table above.

Connect the earthing clamp directly to the work piece in such a way as to maximise the contact

surface of the clamp. The point of connection must be unpainted and free of corrosion.

3. USE

3.1 BEFORE YOU START

Before you start carbon-arc gouging, do the following:

• Select a gouging carbon suitable for the work piece and attach it to the carbon holder.

• Connect the gouging cable to the positive or negative connector depending on the type

of metal to be worked. For more information, see Connecting the gouging cable.

• Adjust the gouging current to a suitable level. By default, the machine uses the

adjustment of the last time the machine was used. For more information on the gouging

current, see the table below.

• Start the power source and start gouging. For more information on the proper way of

performing carbon-arc gouging, see Gouging techniques.

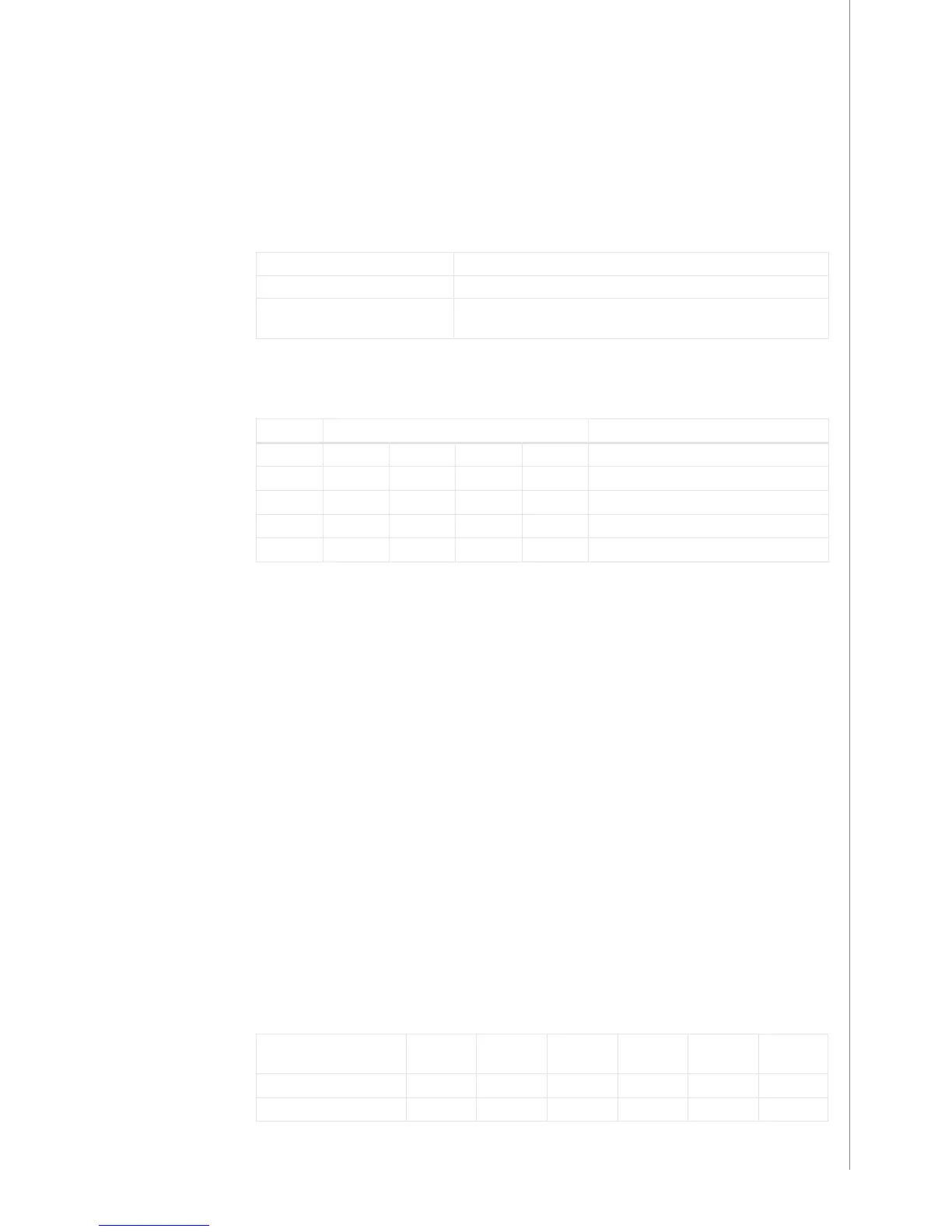

The currents recommended for various gouging carbons.

Round carbon size

5/32”

4.0 mm

3/12”

5.0 mm

1/4”

6.35 mm

5/16”

8.0 mm

3/8”

10.0 mm

1/2”

13.0 mm

Current (A)

80 – 150 110 – 200 170 – 330 230 – 450 300 – 550 460 – 900

Voltage (V)

38 – 41 39 – 42 43 – 46 44 – 48 46 – 50 46 – 50

7

KempGouge ARC 800 / © Kemppi Oy / 1117

Loading...

Loading...