EN

2.10.1 Installation of gas bottle

E

B

D

G

A

F

C

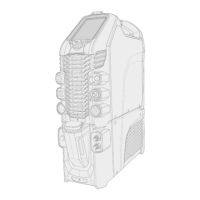

Parts of gas ow regulator

A. Gas bottle valve

B. Pressure regulation screw

C. Connecting nut

D. Hose spindle

E. Jacket nut

F. Gas bottle pressure meter

G. Gas hose pressure meter

NOTE! Always fasten gas bottle properly in vertical position in a special holder on the wall or on a

carriage. Remember to close gas bottle valve after having nished welding.

The following installation instructions are valid for most gas ow regulator types:

1. Step aside and open the bottle valve (A) for a while to blow out possible impurities from the

bottle valve. Note! Watch out for the gas ow.

2. Turn the press regulation screw (B) of the regulator until no spring pressure can be felt.

3. Close needle valve if there is one in the regulator.

4. Install the regulator on bottle valve and tighten connecting nut (C) with a wrench.

5. Install hose spindle (D) and jacket nut (E) into gas hose and tighten with hose clamp.

6. Connect one end of the hose with the regulator and the other end with the power source.

Tighten the jacket nut.

7. Open bottle valve slowly. Gas bottle pressure meter (F) shows the bottle pressure. Note! Do

not use the whole contents of the bottle. The bottle should be lled when the bottle

pressure is 2 bar.

8. Open needle valve if there is one in the regulator.

9. Turn regulation screw (B) until hose pressure meter (G) shows the required ow (or pressure).

When regulating ow amount, the power source should be switched on and the gun

switch pressed simultaneously.

Close bottle valve after having nished welding. If the machine will be out of use for a long

time, unscrew the pressure regulation screw.

3. OPERATION

NOTE! Welding in places presenting an immediate re or explosion hazard is forbidden!

Welding fumes may cause injury, take care of sucient ventilation during welding!

3.1 WELDING PROCESSES

3.1.1 MMA welding

MMA welding, as well as carbon arc gouging, is possible with all Master MLS and Mastertig

MLS power sources with all MLS panel versions when switched to MMA process.

8

Master, MasterTig, MasterCool 10 / © Kemppi Oy / 1112

Loading...

Loading...