Mastertig MLs™ 2300 aDCD / 0743 – 3© keMppi oy

1. PREFACE

1.1. INTRODUCTION

Congratulations on having purchased a KEMPPI product. Properly installed and used Kemppi

products should prove to be productive machines requiring a small amount of regular maintenance.

This manual is to give you a good understanding of the equipment and its safe operation. It also

contains maintenance information and technical specications. Read this manual completely from

front to back before installing, operating or maintaining the equipment for the rst time. For further

information on Kemppi products please contact us or your nearest Kemppi distributor.

The specications and designs presented in this manual are subject to change without prior

notice.

In this document, for danger to life or injury the following symbol is used:

Read the warnings carefully and follow the instructions. Please also study the Operation safety

instructions and respect them when installing, operating and servicing the machine.

1.2. PRODUCT INTRODUCTION

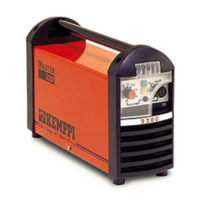

Kemppi Mastertig MLS™ ACDC is a family of TIG welding machines designed for industrial

use, with characteristics especially suitable for welding materials like aluminium and stainless

steel. The equipment consists of power source, function panel and welding torch. The cooling unit

Mastercool 20 is used in water-cooled TIG welding. The welding torch can be either water-cooled

or gas-cooled.

Multipurpose power source Mastertig MLS™ 2300 ACDC of 230 A maximum current is designed

for demanding professional welding, suitable for electrode, TIG and pulsed TIG welding with

both direct and alternating current. The power source is controlled with IGBT transistors with a

frequency of approximately 65 kHz, and the operational functions with a microprocessor.

1.3. SAFETY INSTRUCTIONS

Kemppi welding devices conform to international safety standards. Safety is an important issue

in equipment design and manufacturing. Therefore, Kemppi welding solutions are unparalleled in

safety. There are, however, always certain hazards involved in using welding equipment. Therefore,

to ensure your personal safety and the safety of your working environment, carefully read the safety

instructions below and respect them.

Use of personal protective equipment

• The arc and its reflecting radiation damage unprotected eyes. Shield your eyes and

face appropriately before you start welding or observe welding. Also note the different

requirements for the darkness of the screen in the mask as the welding current changes.

• The arc radiation and spatters burn unprotected skin. Always wear protective gloves, clothing

and footwear when welding.

• Always wear hearing protection if the ambient noise level exceeds the allowable limit (e.g.,

85 dB).

General operating safety

• Exercise caution when handling parts heated in welding. For example, the tip of the welding

torch, the end of the welding rod and the work piece will heat during gouging to a burning

temperature.

• Never wear the device on the shoulder during welding and never suspend it by the carrying

strap during welding.

• Do not expose the machine to high temperatures, as this may cause damage to the

machine.

Loading...

Loading...