© Kemppi Oy 0615

MinarcTig

TM

180 9

EN

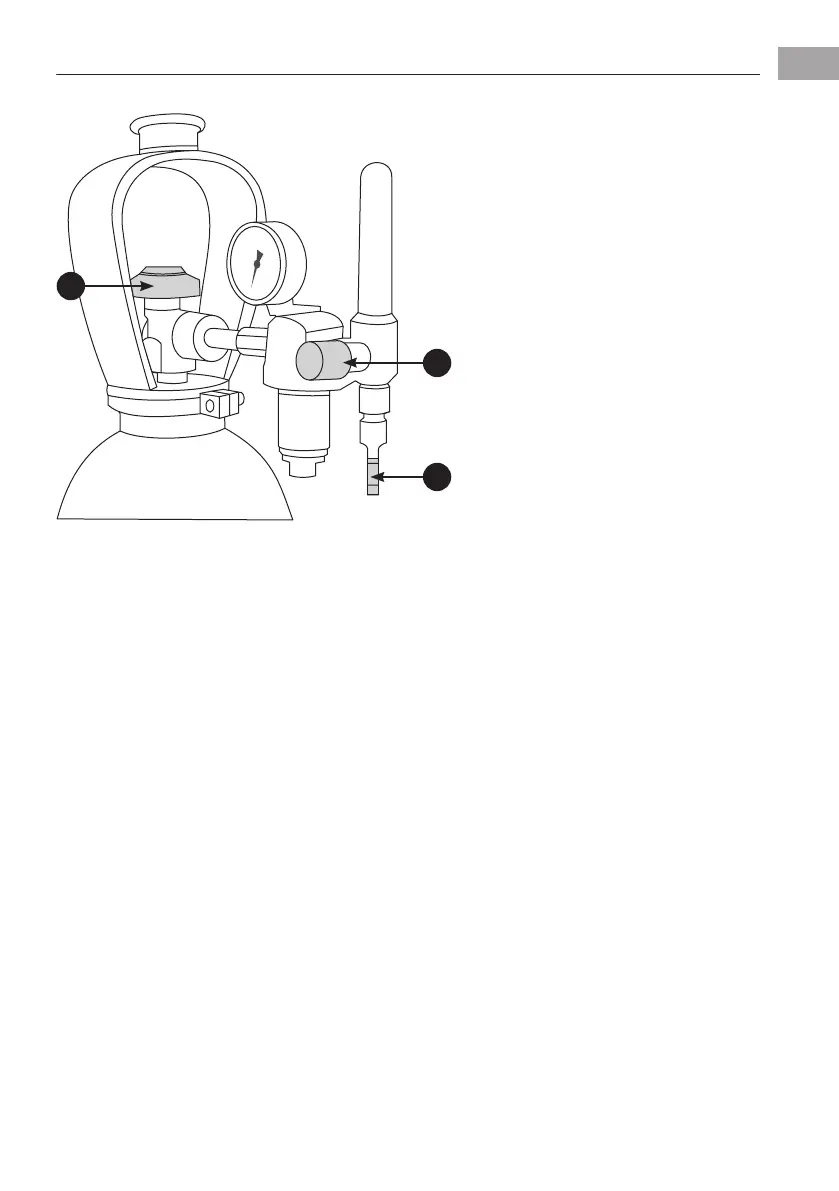

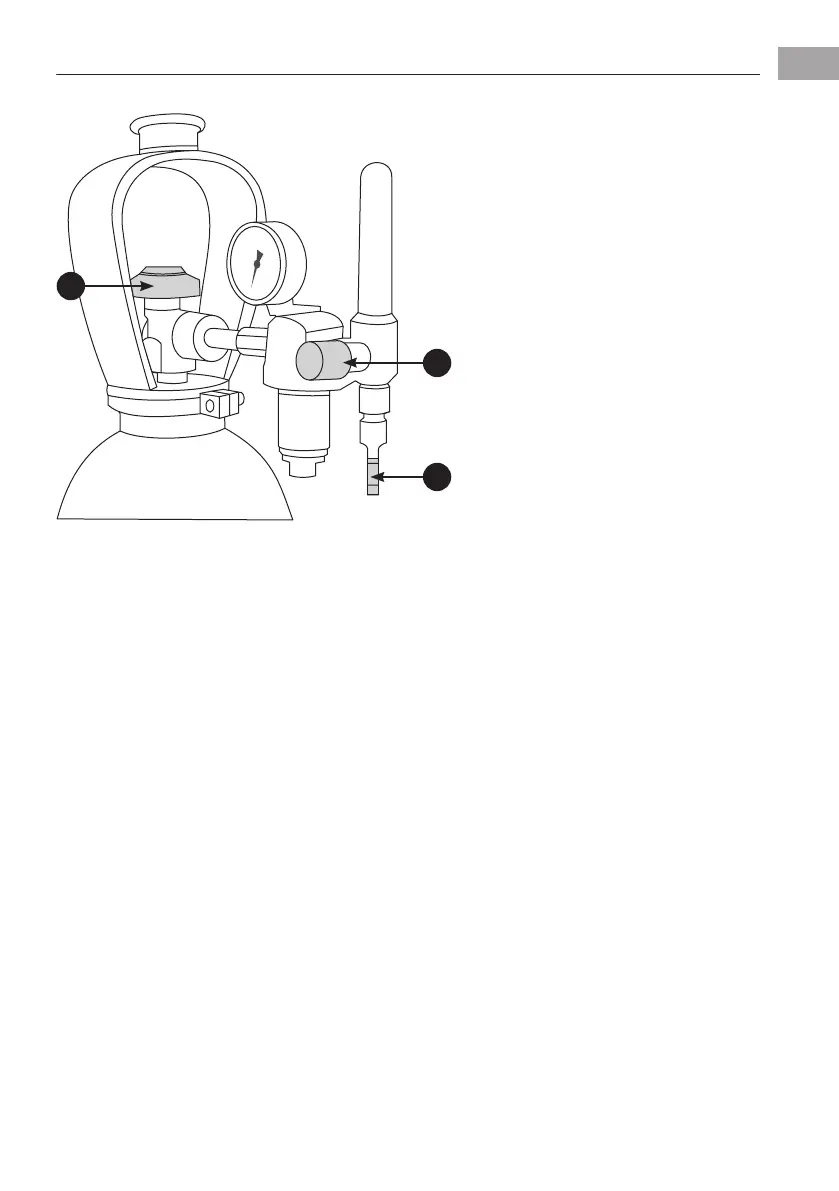

1.Connectthehosetothereducedpressuresideofthecylinderregulator,orowmeter

and tighten the connector.

2.Adjusttheshieldinggasowratewiththeowregulationadjustmentscrew.Asuitable

gasowrateofbetween8–15l/min.

3. Close the cylinder valve after use.

3.4. Welding power selection and electrodes

TIG welding electrodes and gas nozzles

In TIG welding we recommend the use of the WC20 (Grey) type electrode for DC TIG

welding, however other types are available. The welding electrode size (diameter) is

selected depending on the welding current/power to be used. If too small an electrode

is selected for a given the current, the electrode will melt, and conversely too large

an electrode selected for a given current will affect arc ignition. Generally speaking a

1.6 mm Ø tungsten will cover currents up to 150 amps, and 2.4 mm Ø tungsten up to

250 amps DC current. Grind the tungsten electrode to a sharp point at approximately

1.5 times the diameter of the tungsten (length of point). If you touch the electrode to the

work piece during welding, please re-sharpen your tungsten electrode.

MMA welding electrodes

MMA welding electrodes must be used with the correct welding polarity (Normally the

electrode holder is connected to the positive socket, earth return in the negative socket)

1

2

3

Loading...

Loading...