PROTIG 410 / 0537 – 9© KEMPPI OY

2.3. SHIELD GAS

Handle gas bottle with care. There is a risk for injury if gas bottle or bottle valve

is damaged!

For welding stainless steels, mixed gases are normally used. Check that the gas bottle valve

is suitable for the gas. The flow rate is set according to the welding power used in the job. A

suitable flow rate is normally 8 - 10 l/min. If the gas flow is not suitable, the welded joint will be

sporous. Contact your local Kemppi-dealer for choosing gas and equipment.

2.1.9. Remote control units

Connect remote control unit as shown in figures on page 4 or 5. Operation of remote control unit

is explained on page 19.

2.2. INSTALLATION OF TIG/MMA EQUIPMENT

Fasten earthing press of ground cable carefully, preferably direct to welding piece. Contact

surface of press always should be as large as possible.

Clean the fastening surface from paint and rust!

Use in your TIG/MMA equipment 50 mm

2

cables. Thinner cross-sectional areas might cause

overheating of connectors and insulations.

Make sure that the torch being in your use is designed for max. welding current needed by you!

Never use a damaged torch!

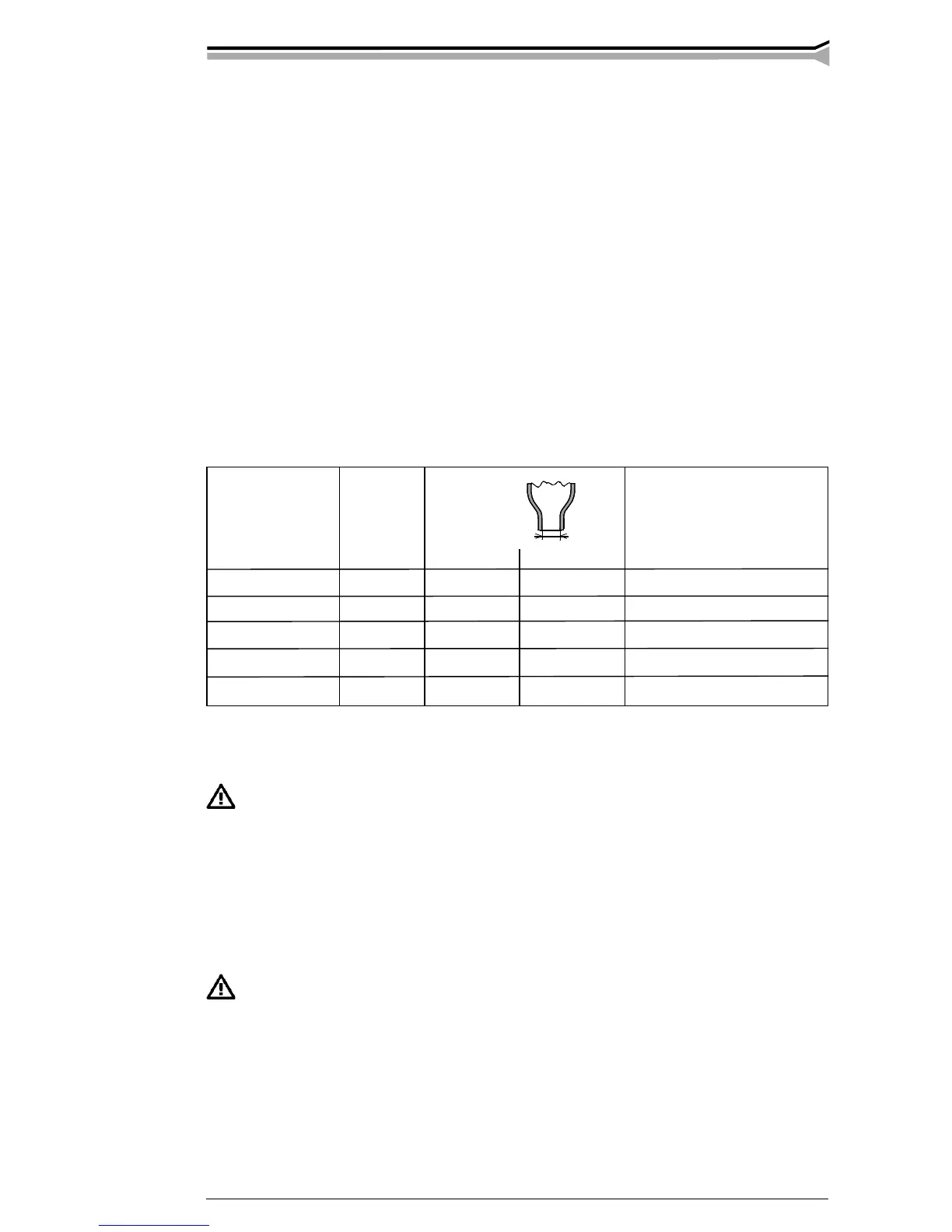

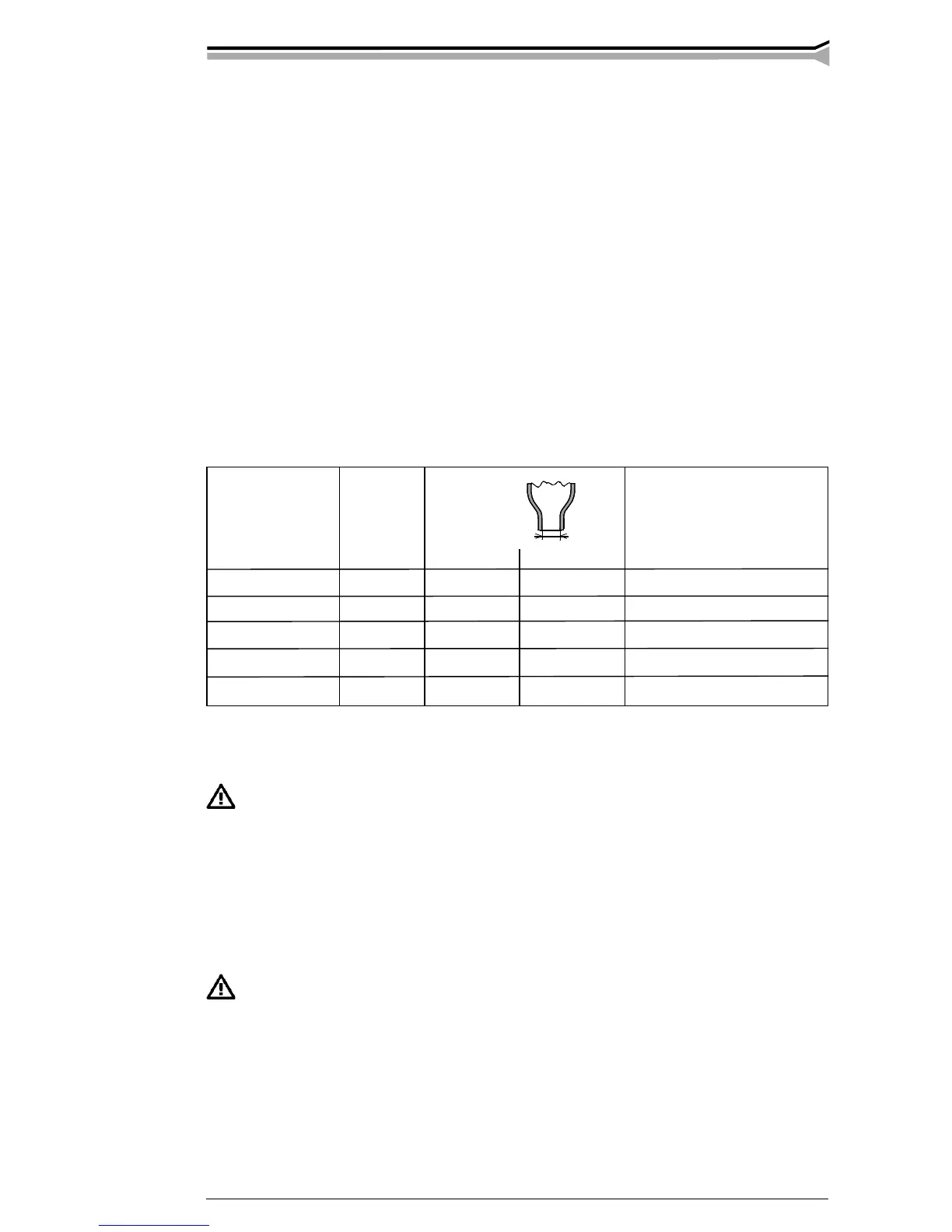

2.2.1. Choice of electrode and flow amount of shielding gas

Use argon as TIG shielding gas. Electrode size and shielding gas flow rate are defined by wel-

ding current size. The table below is given only as a guide.

Welding current Electrode Gas nozzle Gas flow rate

A ø mm number ø mm l/min

5...80 1,0 4 / 5 6,5 / 8,0 5...6

70...150 1,6 4 / 5 / 6 6,5 / 8,0 /9,5 6..7

140...250 2,4 6 / 7 9,5 / 11,0 7...8

225...330 3,2 7 / 8 11,0 / 12,5 8...10

330... 4,0 10 16,0 10...12

2.3.1. Installing gas bottle

Always fasten gas bottle properly in vertical position in a special holder on the

wall or on a carriage. Remember to close gas bottle valve after having finished

welding.

Loading...

Loading...