Boiler Page

Make and model ......................................................... 9

Appliance serial no. on data badge .......... Front Cover

SEDBUK No. % .......................................................... 8

Controls

Time and temperature control to heating ................. 31

Time and temperature control to hot water ............. 31

Heating zone valves ................................................ n/a

TRV’s........................................................................ 12

Auto bypass ............................................................. 12

Boiler interlock .......................................................... 12

For .................................................................... all boilers

Flushing to BS.7593 ................................................. 14

Inhibitor .................................................................... 15

Central heating mode

Heat input ...................................................to be calculated

For assistance see Technical Helpline on the back page

Page

Burner operating pressure ...................................... n/a

Central heating ow temp. ...........measure and record

Central heating return temp. ........measure and record

For combination boilers only

Scale reducer ........................................................... 15

Hot water mode

Heat input ............................................to be calculated

Max. operating burner pressure .............................. n/a

Max. operating water pressure ........ measure & record

Cold water inlet temp ...................... measure & record

Hot water outlet temp. ..................... measure & record

Water ow rate at max. setting ........ measure & record

For condensing boilers only

Condensate drain ..................................................... 26

For all boilers: complete, sign & hand over to customer

For GB, to comply with Building Regulations Part L1 (Part 6 in Scotland) the boiler should be tted in accordance with the

manufacturer’s instructions. Self-certication that the boiler has been installed to comply with Building Regulations can be

demonstrated by completing and signing the Benchmark Commissioning Checklist.

Before installing this boiler, read the Code of Practice sheet at the rear of this book.

BENCHMARK COMMISSIONING CHECKLIST DETAILS

NOTE TO THE INSTALLER:

COMPLETE

THE BENCHMARK COMMISSIONING

CHECKLIST AND LEAVE THESE

INSTRUCTIONS WITH APPLIANCE

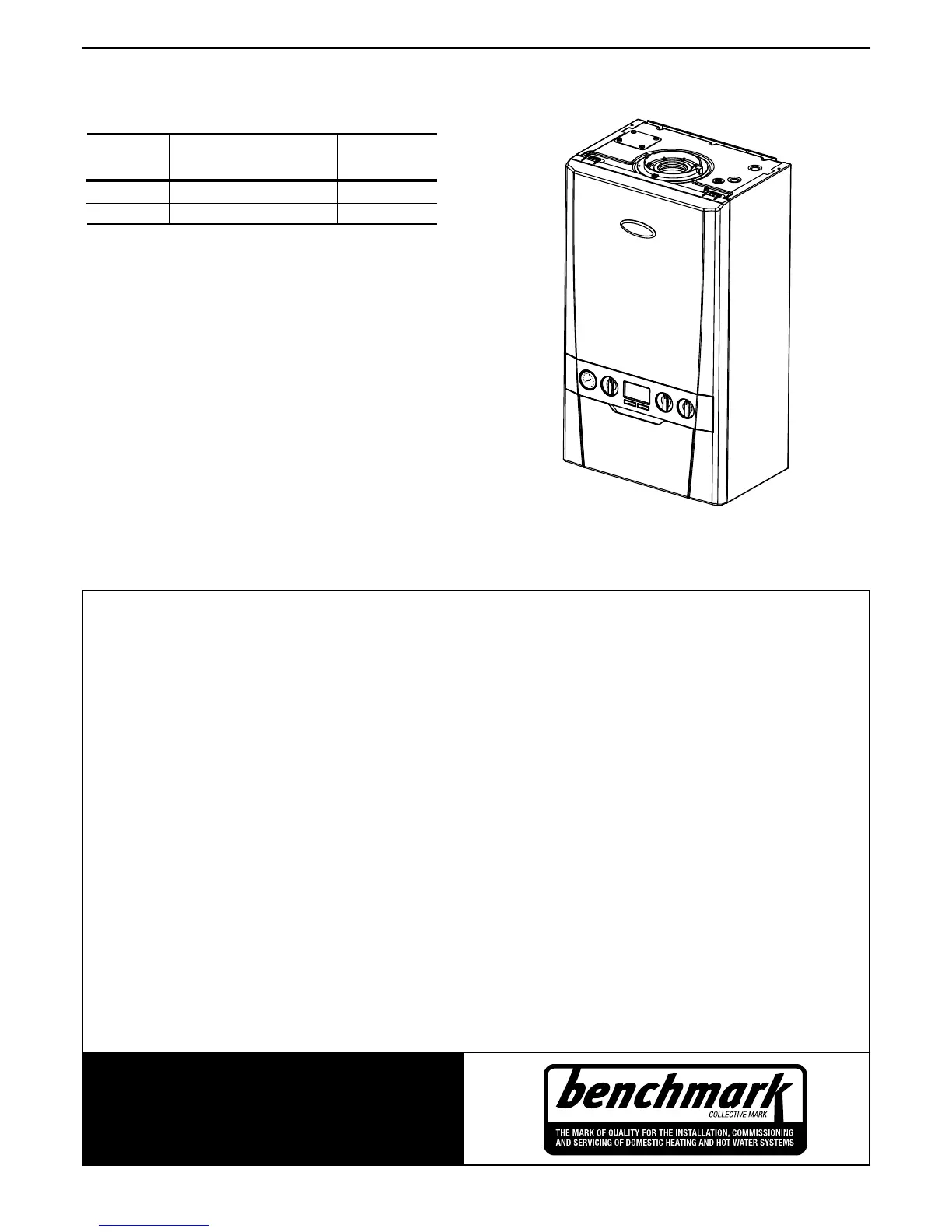

30 35

Gas supply 2H - G20 - 20mbar

Gas Supply Connection 15mm copper compression

Injector Size mm 4.65 4.9

Inlet Connection DHW 15mm copper compression

Outlet Connection DHW 15mm copper compression

Flow Connection CH 22mm copper compression

Return Connection CH 22mm copper compression

Flue Terminal Diameter mm (in) 50 (nominal)

Average Flue Temp-Mass Flow Rate (DHW) 68

o

C - 13g/s 73ºC - 15g/s

Maximum Working Pressure (Sealed Systems) bar (lb/in

2

) 2.5 (36.3)

Maximum Domestic Hot Water Inlet Pressure

bar (lb/in

2

) (kPa)

10.0 (145) (1000)

Minimum Domestic Hot Water Inlet Pressure*

bar (lb/in

2

) (kPa)

1.3 (18.9) (130) 1.3 (18.9)** (130)

Minimum DHW Inlet Pressure to operate at 0.6

bar system pressure

bar 0.5

Electrical Supply 230 V ~ 50 Hz.

Power Consumption W 101 114

Fuse Rating External : 3A Internal : T4A HRC L250 V

Water content CH litre (gal) 1.2 (0.26)

DHW litre (gal) 0.5 (0.11)

Packaged Weight kg 34.40 34.50

Maximum Installation Weight kg 31.40 31.50

Boiler Casing Size Height mm 700

Width mm 395

Depth mm 278

Loading...

Loading...