continued............

2.3 FLUE SYSTEM

IMPORTANT

When installing a replacement boiler a new ue system is recommended. However re-using the existing

boiler ue installation is acceptable if the installer checks and conrms:

• The ue pipe is the approved Marley/Polypipe/Terrain 50mm muPVC solvent weld ue system

• The ue installation is upgraded to the most recent ue standards taking particular care to comply with

ues in voids

• A risk assessment is conducted to conrm the effectiveness of the ue

• The existing ue will last the lifetime of the new appliance

DESIGN

Individual air supply and ue outlet pipes are used as standard.

The material approved for this application which MUST be used are:

- Marley muPVC Solvent Weld System (50mm)

- Polypipe System 2000 muPVC solvent weld (50mm)

- Polypipe Terrain 200 muPVC Solvent Weld System (50mm)

to BS5255 and/or BSEN1566-11 and BSEN1329, are the only systems approved for this application.

The following pipe and ttings are approved.

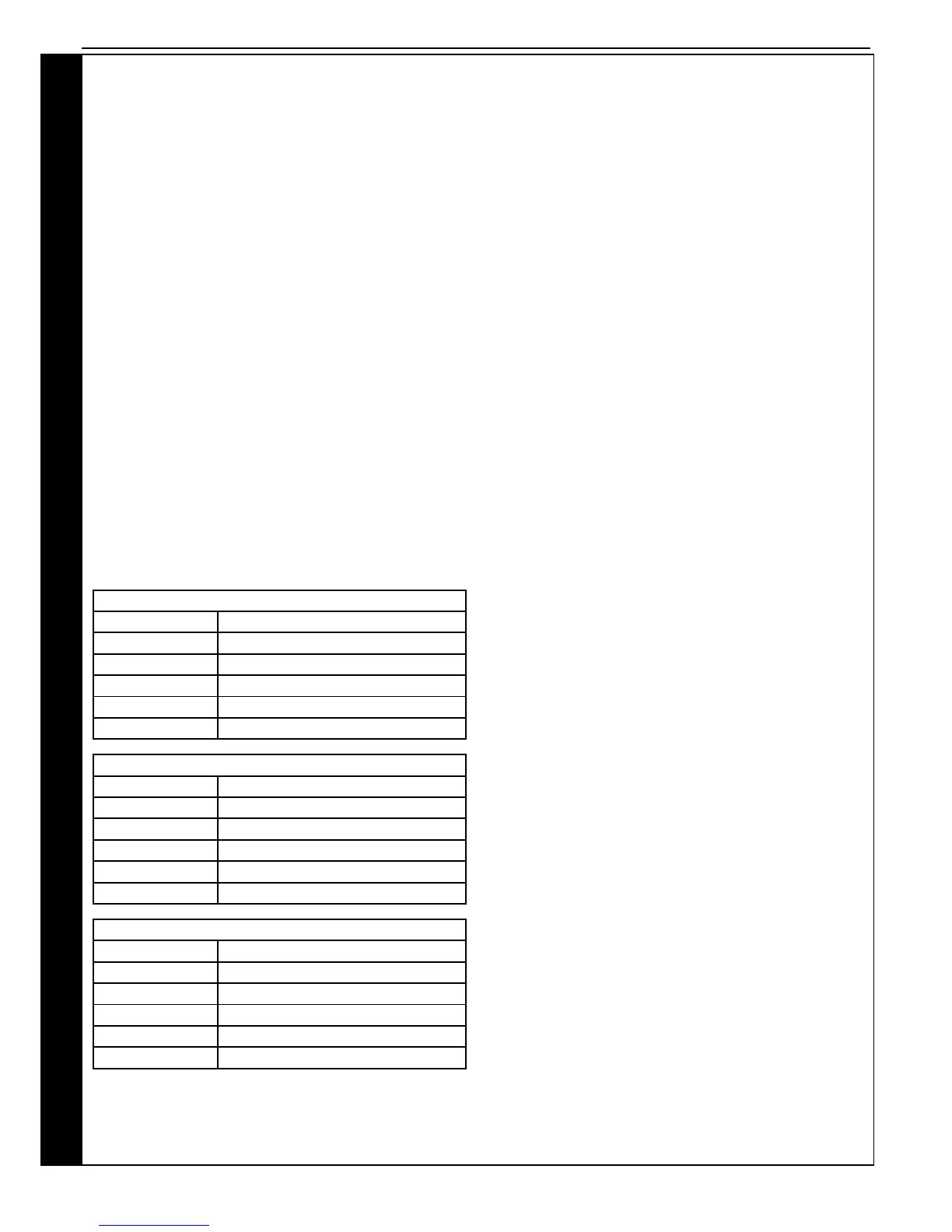

Polypipe System 2000 muPVC solvent Weld System (50mm)

Polypipe Code

MU 301 4m length muPVC wastepipe 5/225

MU 313 50mm x 45 deg muPVC obtuse bend

MU 314 50mm x 92.5 deg muPVC swept bend

MU 310 50mm muPVC straight coupling

MU 316 50mm x 92.5 deg muPVC swept tee

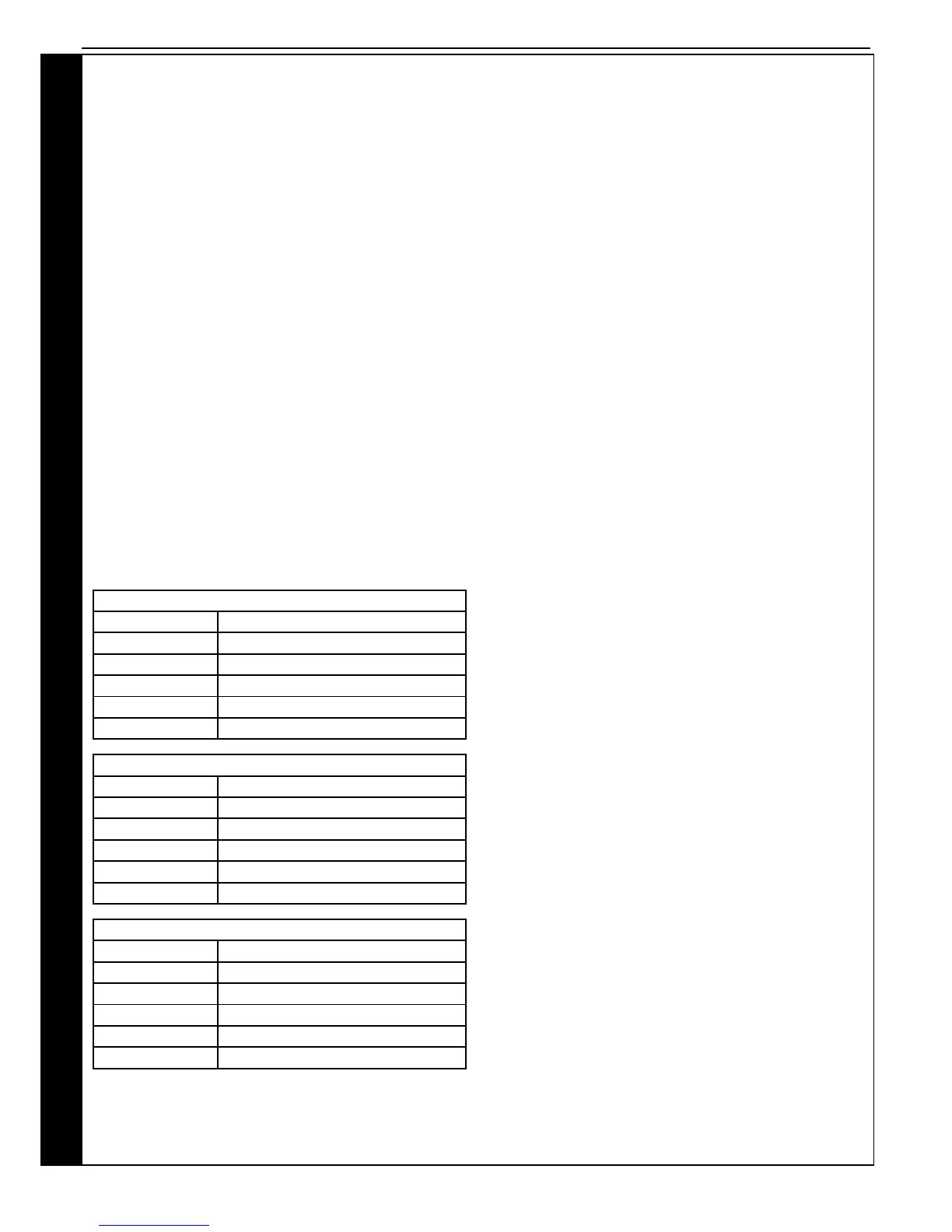

Marley muPVC Solvent Weld System (50mm)

Marley Code

KP 304 50mm x 4m double spigot pipe

KP32 50mm x 45 deg bend

KSC3 50mm straight coupling

KB3 50mm x 88.5 deg bend

KT3 50mm swept tee

Polypipe Terraine Solvent Weld System (50mm)

Polypipe Code

200.2.40 4m length muPVC wastepipe

201.2.135 50mm x 135 deg muPVC bend

200.2.91 50mm x 91

1

/4 deg muPVC swept bend

210.2 50mm muPVC straight coupling

204.2.135 50mm muPVC swept tee

Consideration MUST be given to expansion and contraction of the ue. Refer to Assembly Practice (Section 2.12) in this

installation and Servicing Instructions for further guidance.

Loading...

Loading...