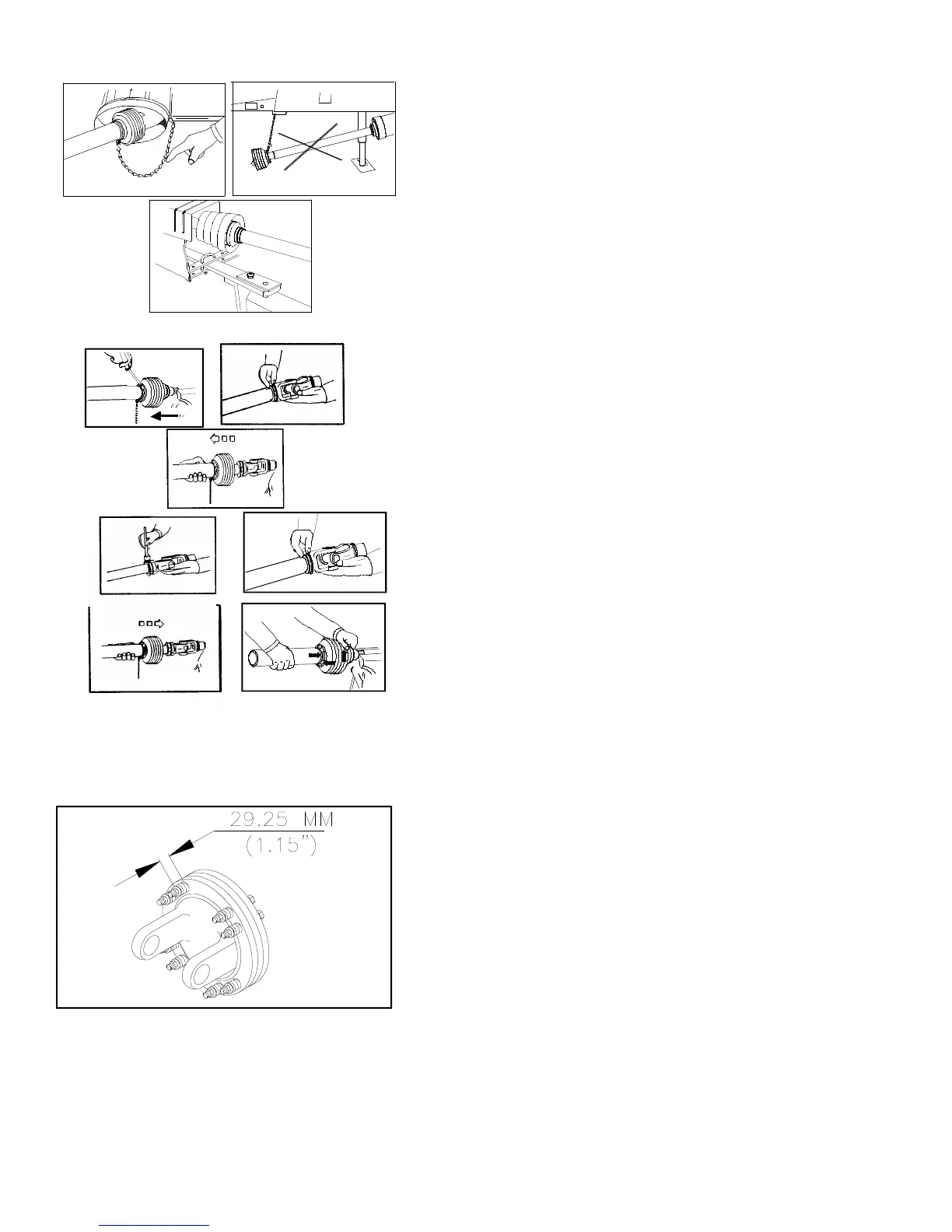

G. Assembling guard:

1. Grease collar groove and inner profile tube.

2. Fit shield tube into collar by centering the

slots over the collar teeth.

3. Align cone, centering grease nipple to

grease filling hole on collar. Press down-

ward to connect.

4. Make sure the three collar tabs are prop-

erly engaged by tapping on cone.

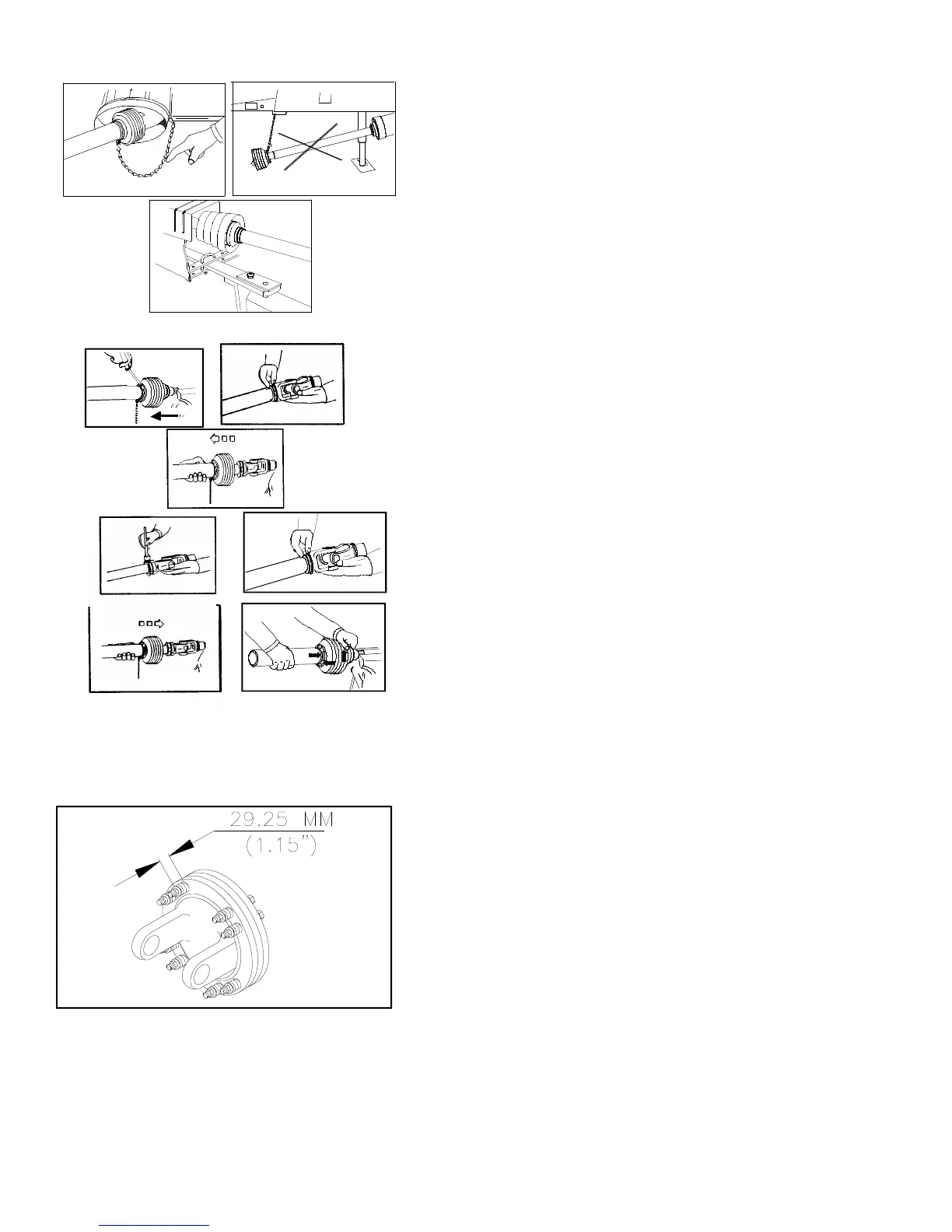

H. Slip Clutch - preset at factory

Damage may occur to other parts of the grain

cart if the spring tension is not set properly.

Correct operating procedure of the slip clutch

is to have it slip slightly with each use.

1. If adjustment is necessary, length from

flange surface to under side of nut should

be 29.25 MM (1.15”).

2. Tighten nuts following an alternating cross

pattern until reaching the height specified.

Check that height is constant for all

springs.

3. If too much slippage occurs, only tighten

each nut a quarter of a turn at a time.

This quarter turn will increase the torque

approximately 500-750 inch lbs.

4. After extended time without use, the slip

clutch may “freeze up”. It is very impor-

tant at the beginning of each season to

loosen the nuts, slip the clutch, and re-

tighten the nuts to the correct length.

1. Chains must be fitted to allow sufficient

articulation of the shaft in all working po-

sitions. Care must be taken to be sure

that chain does not become entangled with

drawbar hitch or other restrictions during

operation or transport of machine.

2. The PTO drive shaft must not be sus-

pended from the chain when PTO is not

in use or unattached from drive unit.

3. If chain should become unattached, do

not attempt to reattach it with the PTO

engaged. Turn off PTO and tractor engine

before making any repairs. If chain is

missing, replace it before use.

F. Dismantling guard:

1. Keep cone pressed downward and release

collar tabs by pushing with a screwdriver.

Push cone off tube.

2. Spread collar to remove from tube.

3. Slide tube off the shaft.

OM02520

G1

G2

G3

G4

E1 E2

E3

F1

F3

F2

Loading...

Loading...