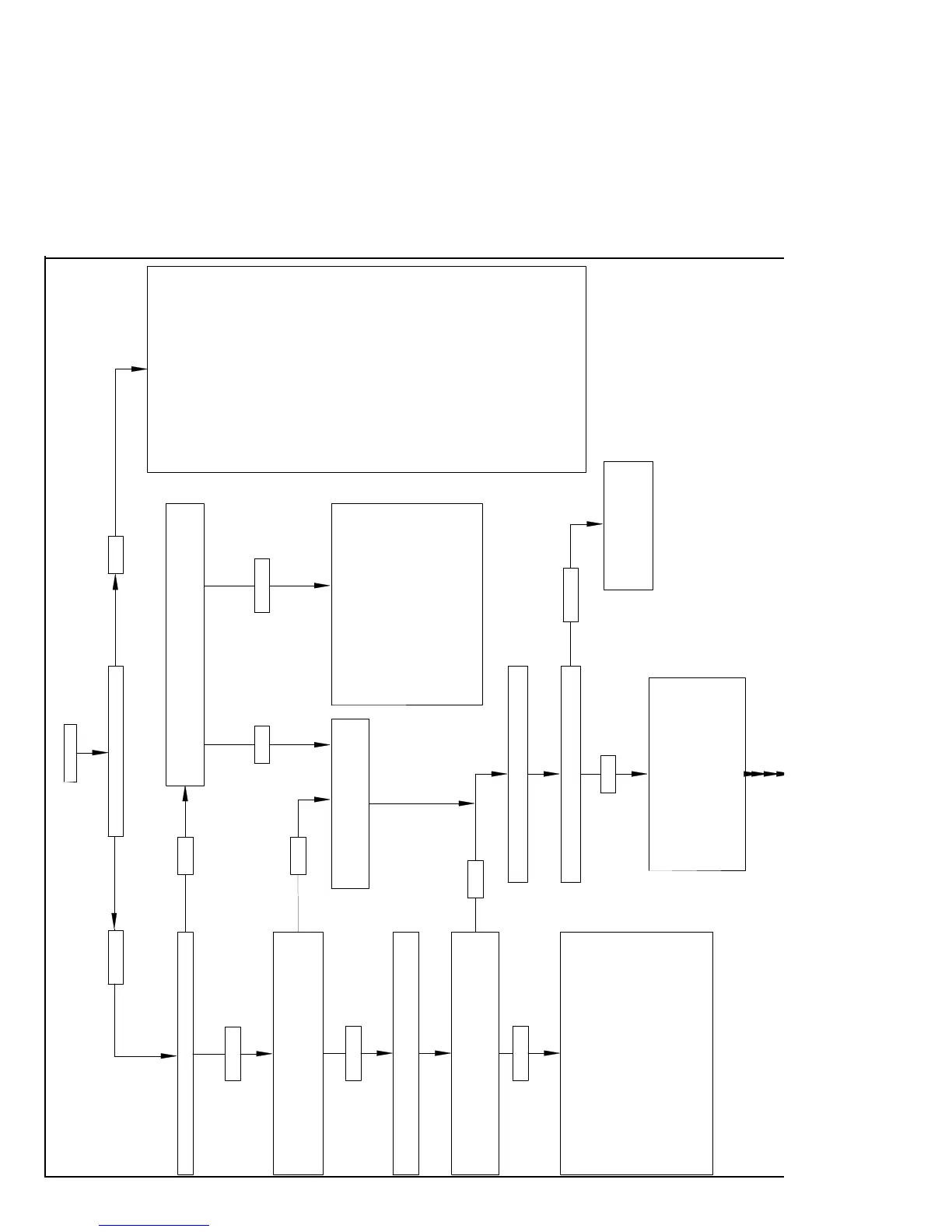

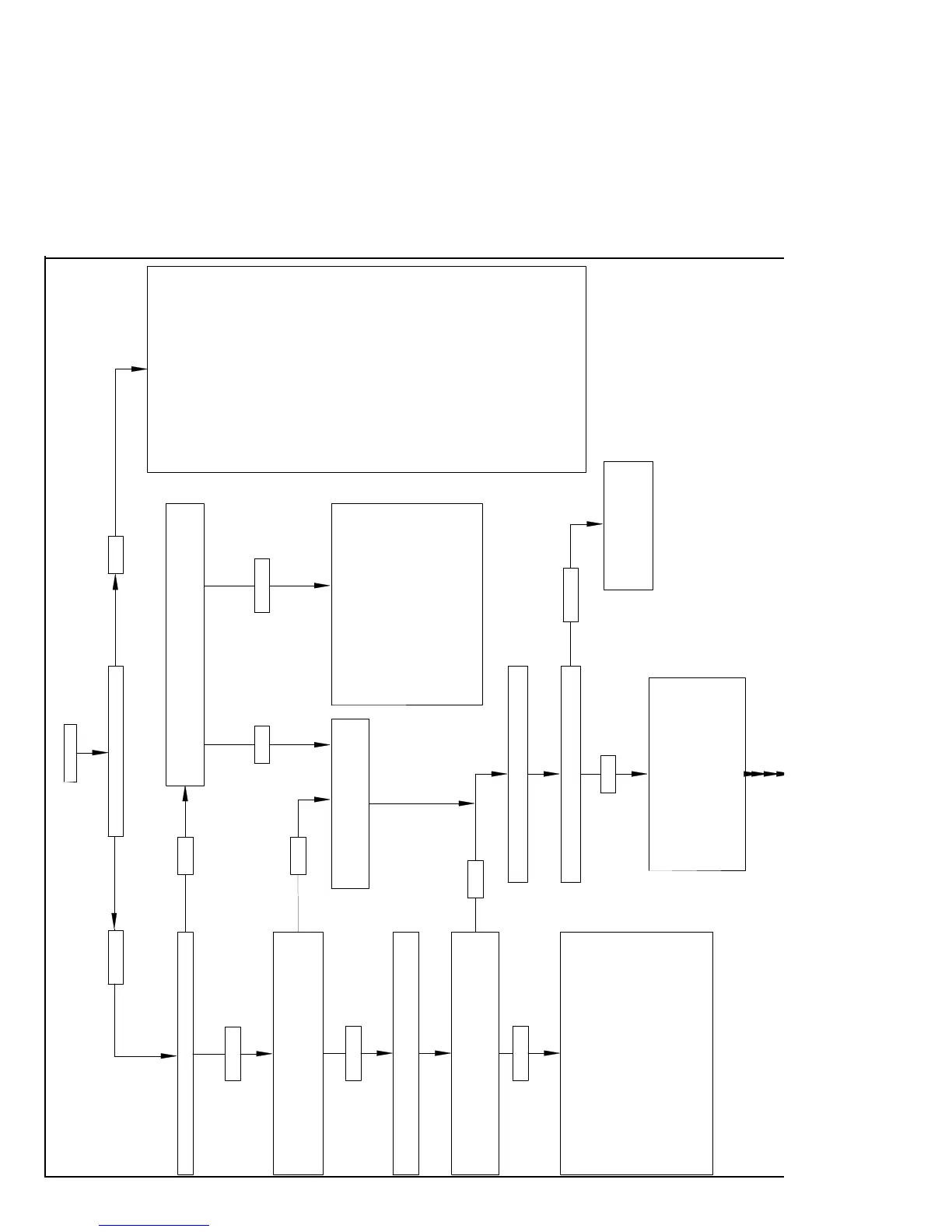

IF YOUR DISPLAY IS UNSTABLE, OR FLASHES " RANGE",

DISCONNECT THE J-BOX CORD FROM THE INDICATOR.

IS THE DISPLAY STILL UNSTABLE?

YOUR INDICATOR IS PROBABLY

NOTE: BE AWARE OF ELECTRICAL

INTERFERENCE THAT MIGHT AFFECT

YOUR SCALE SUCH AS: MOBILE

PHONES, CB RADIOS, RADIO

TOWERS, ELECTRICAL MOTORS, ETC.

ALSO MAKE SURE LOAD CELL CABLES

ARE NOT ATTACHED TO HYDRAULIC

LINES OR RESERVOIR BECAUSE OF

(A hair dryer works great.)

DRY OUT YOUR J-BOX.

IS THE READING ON THE INDICATOR STABLE?

RESPOND TO YOUR WEIGHT WHEN YOU STAND,

YES

STAND ON, OR HANG YOUR WEIGHT OVER,

EACH LOAD CELL. DOES THE INDICATOR

OR HANG, ON THE SCALE?

YES

START

DOES THE INDICATOR COME ON?

NO

NO

NO

YES

YOUR INDICATOR IS PROBABLY NOT SET-UP

AND CALIBRATED CORRECTLY. CHECK THE

DECAL ON THE BOTTOM OF THE INDICATOR.

TO. BY PRESSING THE "ON" KEY WHILE THE

NUMBERS. WRITE THESE DOWN AND SEE IF

ARE THE READINGS ALL POSITIVE?

IF NOT THE LOAD CELL IS UPSIDE DOWN.

YES

DOES THE SCALE WEIGH YOU

APPROXIMATELY THE SAME

OVER ALL LOAD CELLS?

(BUT NOT YOUR WEIGHT)

YES

THE DECAL SHOWS WHAT TYPE OF LOAD

CELLS THE INDICATOR WAS CALIBRATED

INDICATOR IS ALREADY ON, YOU WILL GET

THE INDICATOR'S "SET-UP" AND "CAL"

THEY COMPARE TO THE SET-UP AND

INDICATOR. CONTACT YOUR DEALER FOR

CALIBRATION NUMBERS ON THE

FURTHER INFORMATION.

CHECK ALL J-BOX AND

LOAD CELL CABLES FOR

CUTS OR PINCHED/FLAT SPOTS

REMOVE THE COVER FROM YOUR J-BOX

NO

DEFECTIVE. TRY ANOTHER

INDICATOR TO VERIFY.

STATIC ELECTRICITY.

IS THERE MOISTURE INSIDE THE J-BOX?

LOOK FOR LOOSE CONNECTIONS.

IF YOU WATCH YOUR INDICATOR

DISPLAY WHILE MOVING THE WIRES

INSIDE THE J-BOX AROUND, AND BY

PRESSING ON THE J-BOX PRINTED

CIRCUIT BOARD, YOU WILL SEE IF

THERE IS A LOOSE CONNECTION OR

BAD SOLDER JOINT.

NO

YES

BAD INDICATOR: IF YOU SUSPECT A

BAD INDICATOR, THE EASIEST WAY TO

CHECK, IS TO TRY ANOTHER

INDICATOR. EVEN IF THE INDICATOR IS

A DIFFERENT MODEL, OR IS SET-UP

FOR A DIFFERENT SCALE, IT AT LEAST

SHOULD COME ON.

POOR CONNECTION: POOR

CONNECTIONS CAN BE TRICKY. IF IN

DOUBT, DON'T JUST TIGHTEN THE

CONNECTION, TAKE THEM APART AND

CLEAN THEM FIRST. ANY CONNECTION

WITH RUST OR PAINT SHOULD BE

SANDED OR WIRE BRUSHED.

NO

±

10.5 AND 14.5 VOLTS DC. IF USING A

BAD BATTERY: IF YOU SUSPECT THE

BATTERY, TRY REPLACING IT WITH

ANOTHER ONE. DON'T BE FOOLED IF

USING A VOLTMETER TO TEST YOUR

BATTERY. A WEAK BATTERY MAY TEST

GOOD IF CHECKED WHEN THERE IS NO

LOAD ON THE BATTERY.

BAD POWER CORD: MAKE SURE THE

POWER CORD'S RED WIRE IS

CONNECTED TO THE PLUS (+) POSITIVE

SIDE AND THE BLACK (-) NEGATIVE

WIRE IS CONNECTED TO THE NEGATIVE

SIDE. IF USING A MULTIMETER TO

CHECK FOR VOLTAGE, MEASURE

BETWEEN PIN 1 (POS) AND PIN 2 (NEG).

THE METER SHOULD READ BETWEEN

TRACTOR POWER CORD, THE BLACK

WIRE ON THE TRACTOR PLUG IS

POSITIVE AND THE WHITE WIRE IS

NEGATIVE.

TROUBLE SHOOTING GUIDE FOR THREE POINT

(3 LOAD CELL) SCALE SYSTEMS

WHILE USING THE TROUBLESHOOTING GUIDE, SEVERAL SECTIONS REFER TO STANDING OR HANGING YOUR

WEIGHT OVER EACH LOAD CELL. THIS IS AN IMPORTANT PART OF TROUBLESHOOTING YOUR SYSTEM,

(WE CALL IT WALKING THE CORNERS). THIS IS DONE TO CHECK THE SCALES ABILITY TO WEIGH YOU

CORRECTLY WITH ALL FOUR LOAD CELLS. ALTHOUGH IT IS SOMETIMES DIFFICULT TO GET YOUR WEIGHT

DIRECTLY OVER EACH LOAD CELL, IT IS AN IMPORTANT PART OF THE TEST.

Loading...

Loading...