OM02557

Fig.5

ADJUSTABLE GEARBOX

OPERATION

Gearbox is pre-aligned at factory and welded,

centered on auger tube. Given time and wear,

gearbox may become out of alignment, caus-

ing excessive vibration and wear to the cart.

To correct this, follow these steps.

1. Break the two tack welds holding the plate

to the cart.

2. With tack welds broke, loosen the (4)

5/8” bolts. Be sure not to loosen them all

the way, auger may drop down, causing

total misalignment, or even injury.

3. With gearbox and plate free to move,

position auger so that it is center with

auger tube. Once centered, retighten bolts.

4. Clear work area and test run auger and

see that auger is centered with auger tube.

5. Once auger is set and centered with tube,

check tightness on bolts and tack weld

plate back into place. Run 2 tack welds

about 1” long on 2 sides of plate.

1

FRONT

2

3

4

5

6

6

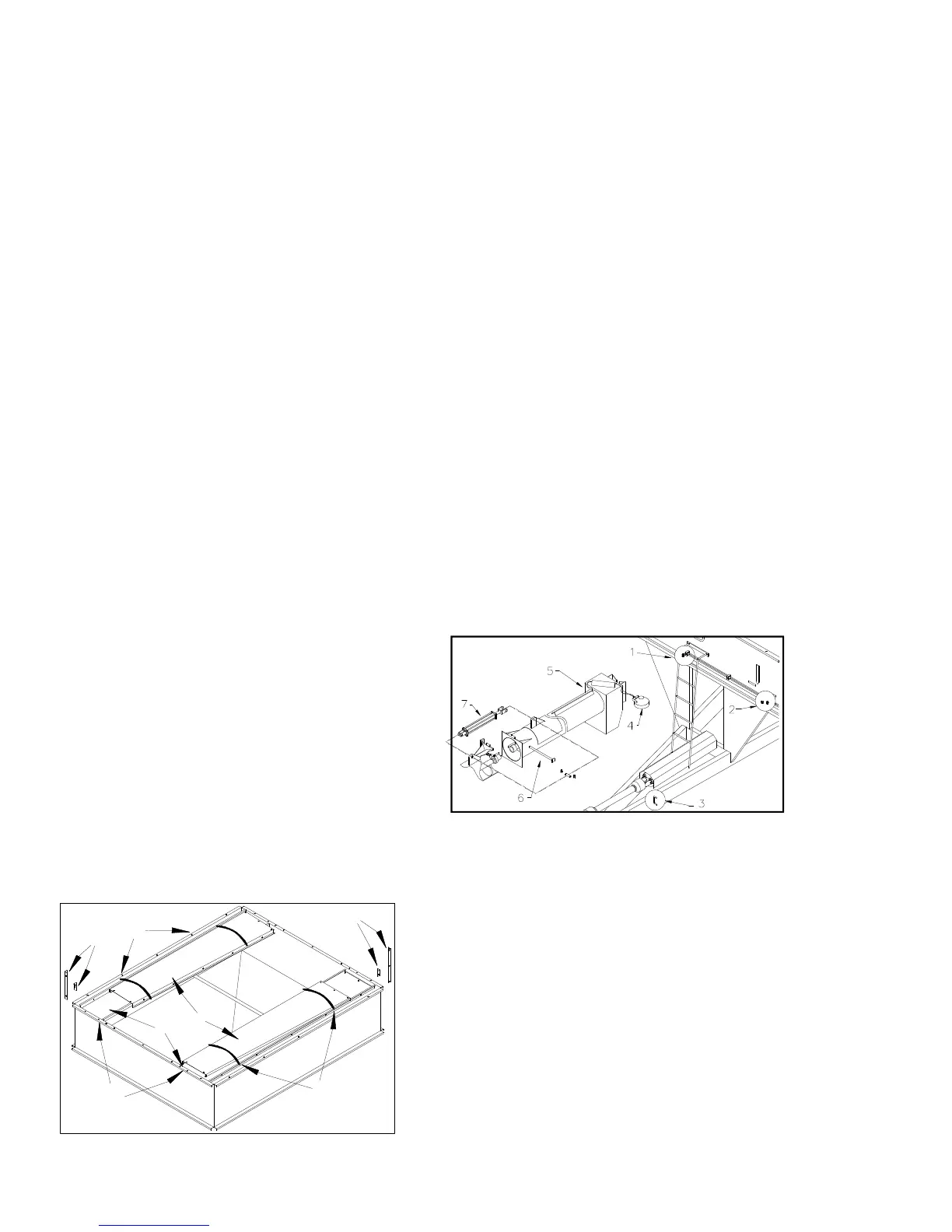

tom side of the cart for the flow control gate.

(3) U-brackets are welded along the inside

channel for protection of the hydraulic hoses.

Run the hoses between these brackets. (4)

Install work light to upper auger, securing it

to the brackets used for the upper bearing.

(5) Feed wire used for the light through the

channels welded to the backside of the upper

auger. (6) Install the upper auger so that it is

in the rest position, resting on the rest bracket

located to the back of the cart. Position au-

ger, lining up the holes where auger is hinged.

Once aligned secure hinge pin with expansion

pin. Refer to page 21 for hardware listing.

Auger screws will pre-align once upper auger

is extended. (7) Install hydraulic cylinder and

secure with cylinder pins and clips. The upper

auger or cylinder may have to be slightly

extended for proper alignment of cylinder pin

holes. Connect the cylinder hoses to the two

ports located below the lower auger tube.

Secure all hardware, wiring, and hydraulic

hoses and check for leaks.

SIDEBOARDS

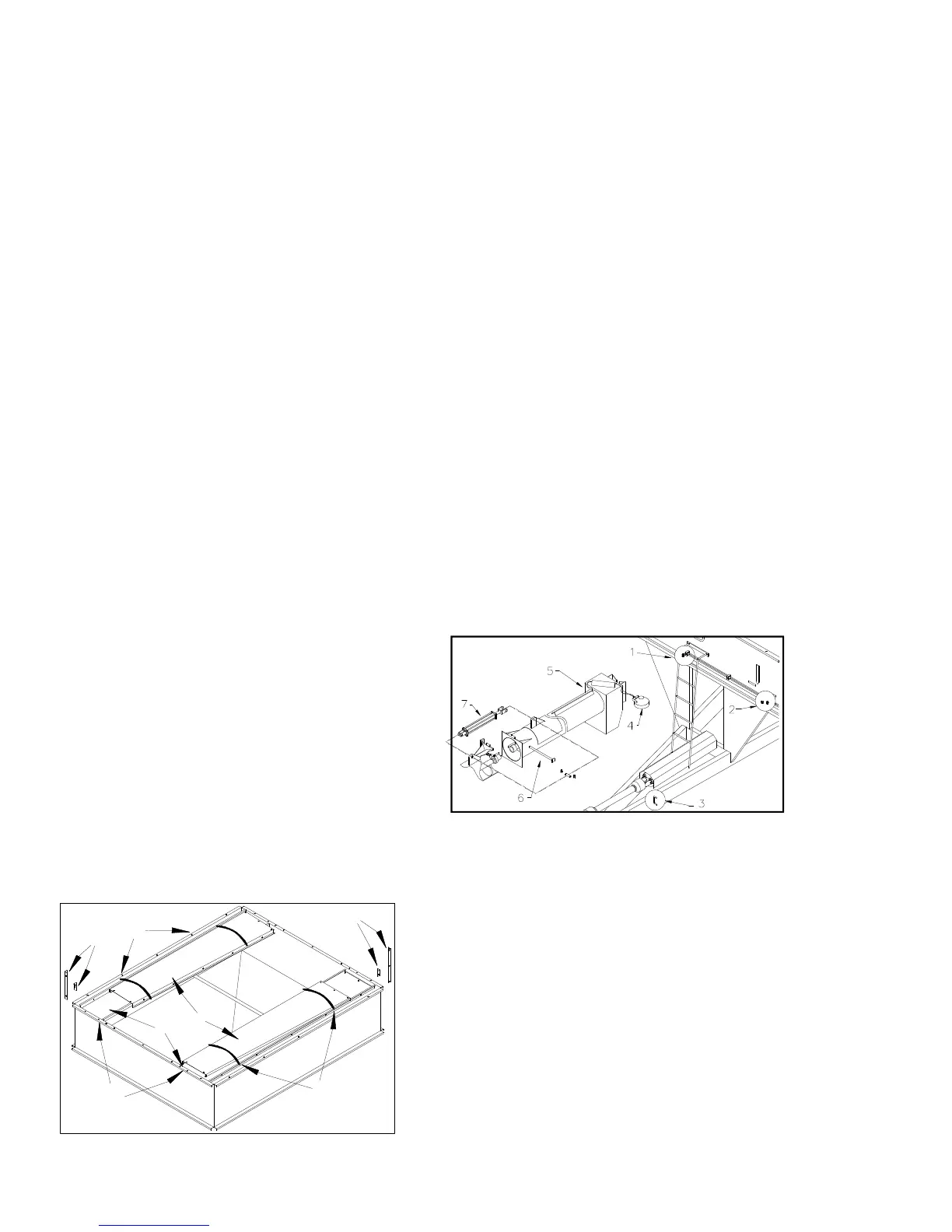

Refer to Fig. 4 for locations of each step.

The side boards should be assembled with

care so the paint does not get scratched. (1)

Cut the bands that hold the sideboards to-

gether. (2) Remove the mounting brackets on

the front of the cart. Do not remove side

mounting brackets until after end boards are

in place. Take note that the bolts used for

shipping should also be used for the final

mounting of the sideboards. (3) Stand the

end boards up one at a time using the center

bar on the cart and the cart sides for support.

Swing the end boards around into their final

mounting positions and put two bolts in them

to keep them in place. (4) Remove the side

mounting brackets, also saving these bolts.

(5) Lift the sideboards into place and bolt

them to the cart. (6) Take the corner brack-

Fig.4

ets out of the hardware bag tied to the frame

of the cart. Bolt the corner brackets on the

outside of the sideboards using the top set of

holes on each corner. Use the small corner

bracket on the inside of the sideboards. This

small bracket is reversible so it can be used

on all four corners. Bolt the small bracket on

the bottom set of holes on each corner mak-

ing sure that the bracket covers any gaps

that may exist in the corners. Before using

cart check that all bolts are in place and

tightened. Refer to page 28 for complete

hardware listings and final assembly illustra-

tion.

OM03187

Loading...

Loading...