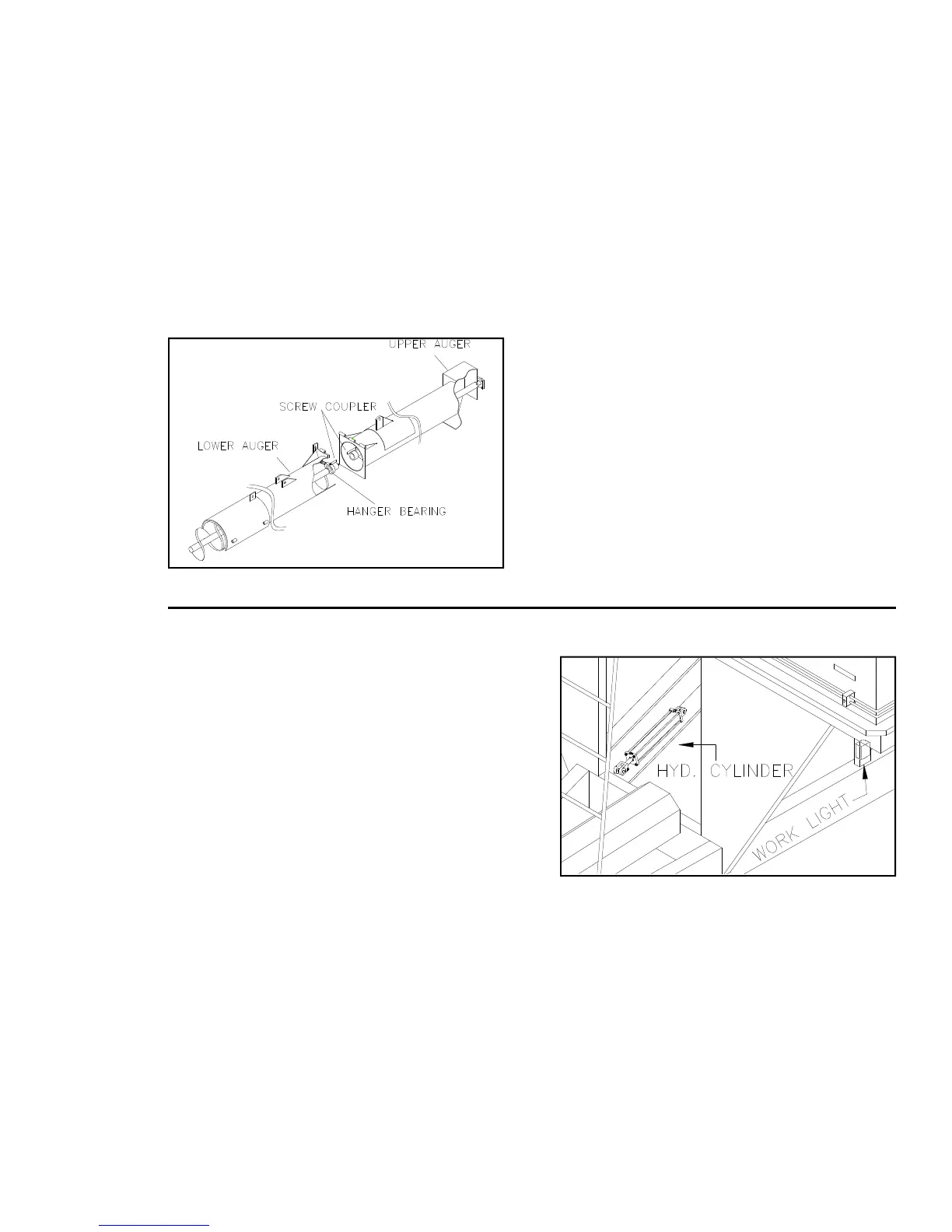

AUGER SYSTEM

Annually check all bolts, nuts, and set screws.

Perform lubrication as specified. The vertical

auger screw on upper and lower auger tubes

are designed to self align while extending upper

auger. (See fig. 2 for exact location.) If auger

is still misaligned, check the gear box to see

that all hardware is secure and tight. Follow

the instructions listed on page 18 for gear

box adjustment.

OM02525

FLOW CONTROL GATE

The Flow Control Gate is designed to prevent

grain form putting an excess load on the

horizontal auger during initial start-up. If gate

is not working properly check:

-- the hyd. cylinder, making sure hoses are

attached properly, clevis pins are secure, and

fluid level in cylinder is at its recommended

level.

-- for any debris that may have wedged be-

tween gate and auger tube.

-- Indicator rod. See that it is not binding up.

INDICATOR ARM

The Indicator Arm lets the operator know the

position of the flow control gate, open or

closed. This arm is connected to the flow

control gate. If the indicator arm is not work-

ing properly see that the hardware connecting

the indicator rod is secure with flow gate and

not binding up. See flow control gate for fur-

ther adjustments.

OM02556

Fig.3

Fig.2

ASSEMBLY

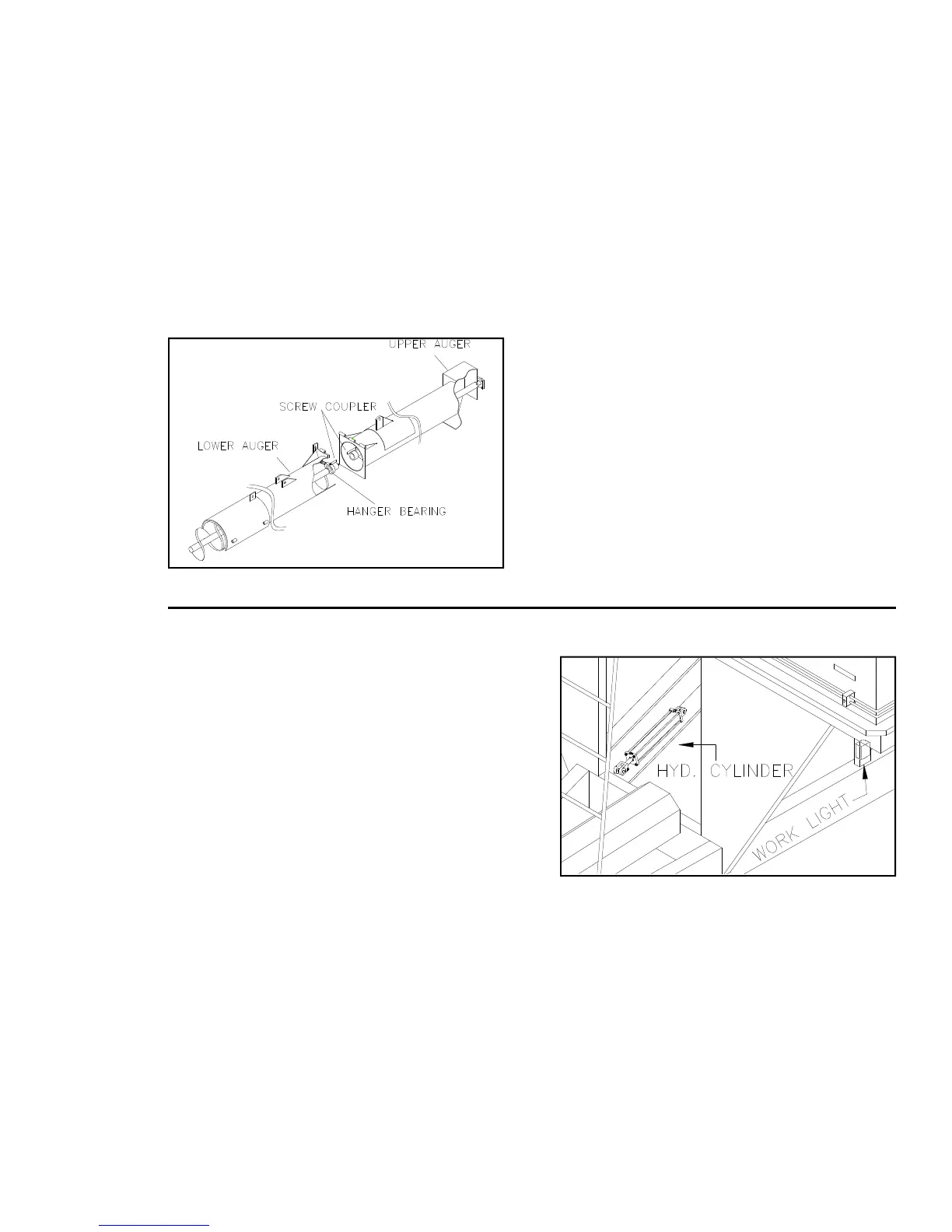

Some assembly is required before initial use

and operation. All Grain Carts are shipped

without the upper auger, work light, and hy-

draulic cylinder and hoses installed. The 690

model is shipped without the sideboards in-

stalled. If the dealer hasn’t already installed

all equipment, please refer to the following

guidelines for proper location and installation.

Before operation, double check to see that all

components are installed and working properly

to prevent damage to cart or personal injury.

All components of cart are shipped with cart

and stored in the least likely spot to be

damaged during shipping. All carts are shipped

with 1 upper auger, 1 work light, 1 hydraulic

cylinder, and 4 hydraulic hoses. The 690 Cart

is also shipped with 4 sideboards, 4 corner

braces, and 4 corner filler plates. The upper

auger is noticeable, located behind the ladder.

The hydraulic hoses are secured with cable

ties around the ladder. The hydraulic cylinder

is located on the right frame channel directly

behind front frame standard. The work light is

located, opposite the hydraulic cylinder, in a

box taped to the channel support. See Fig. 3

for locations.

The corner braces and filler plates are lo-

cated in a hardware bag on the frame oppo-

site the hyd. cylinder. The 690 sideboards

are shipped mounted flat on the top of the

cart.

INSTALLATION

Refer to (Fig. 5). Remove hydraulic hoses

from ladder by cutting the cable ties used in

shipping. Be careful not to cut hoses. On one

end of each hose is a hydraulic coupler that

will attach to the tractor. Connect the oppo-

site end to the cart. (1) Connect the two

male hoses to the female fittings used for the

upper auger. To prevent damage to these

hoses, secure to outside rail of ladder. (2)

The remaining 2 hoses will attach to the bolts

Loading...

Loading...