SERVICE

LUBRICATION AND MAINTENANCE

To keep your grain cart in top operating condition and get the maximum performance and reliability,

lubrication and a periodic inspection is a must.

The lubrication locations and recommended schedule are as follows:

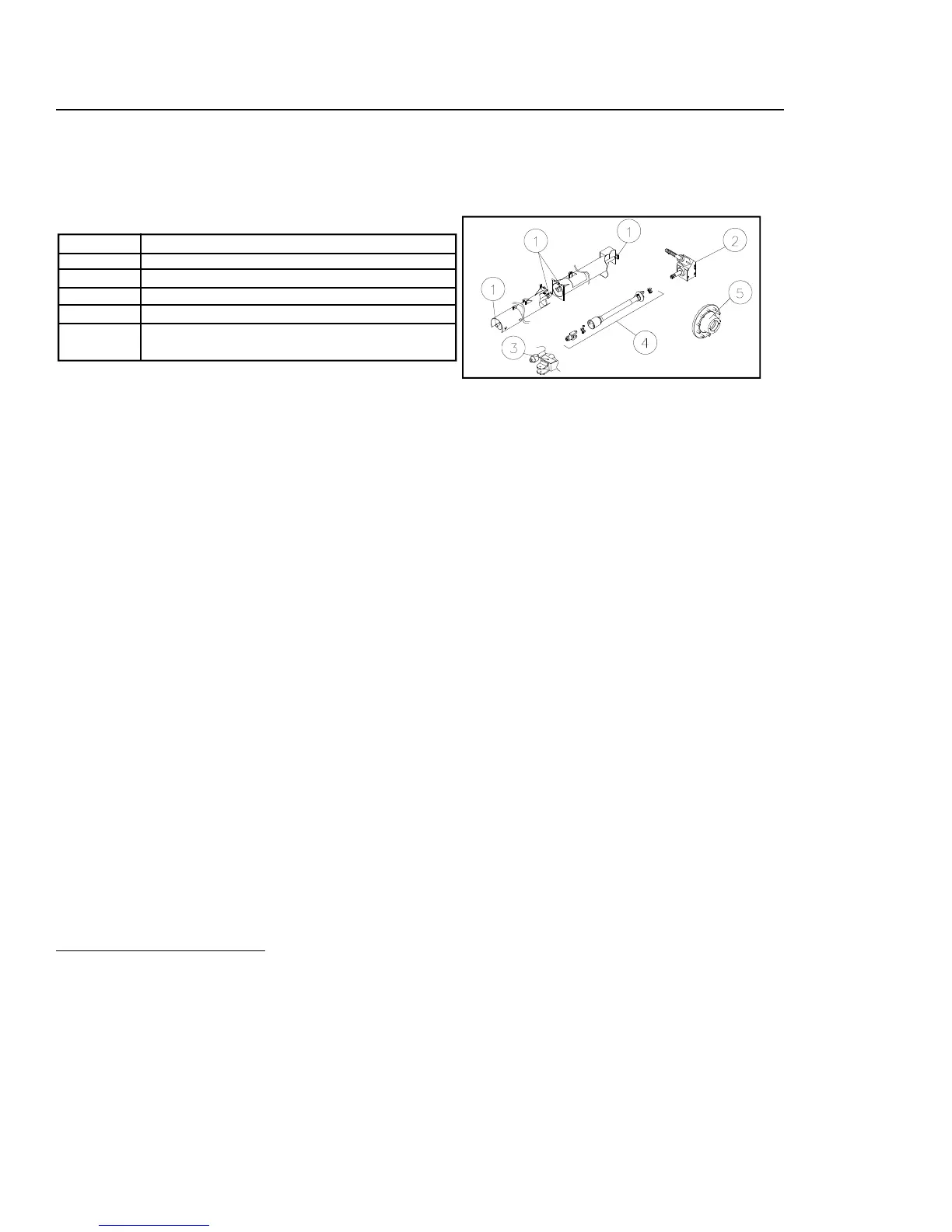

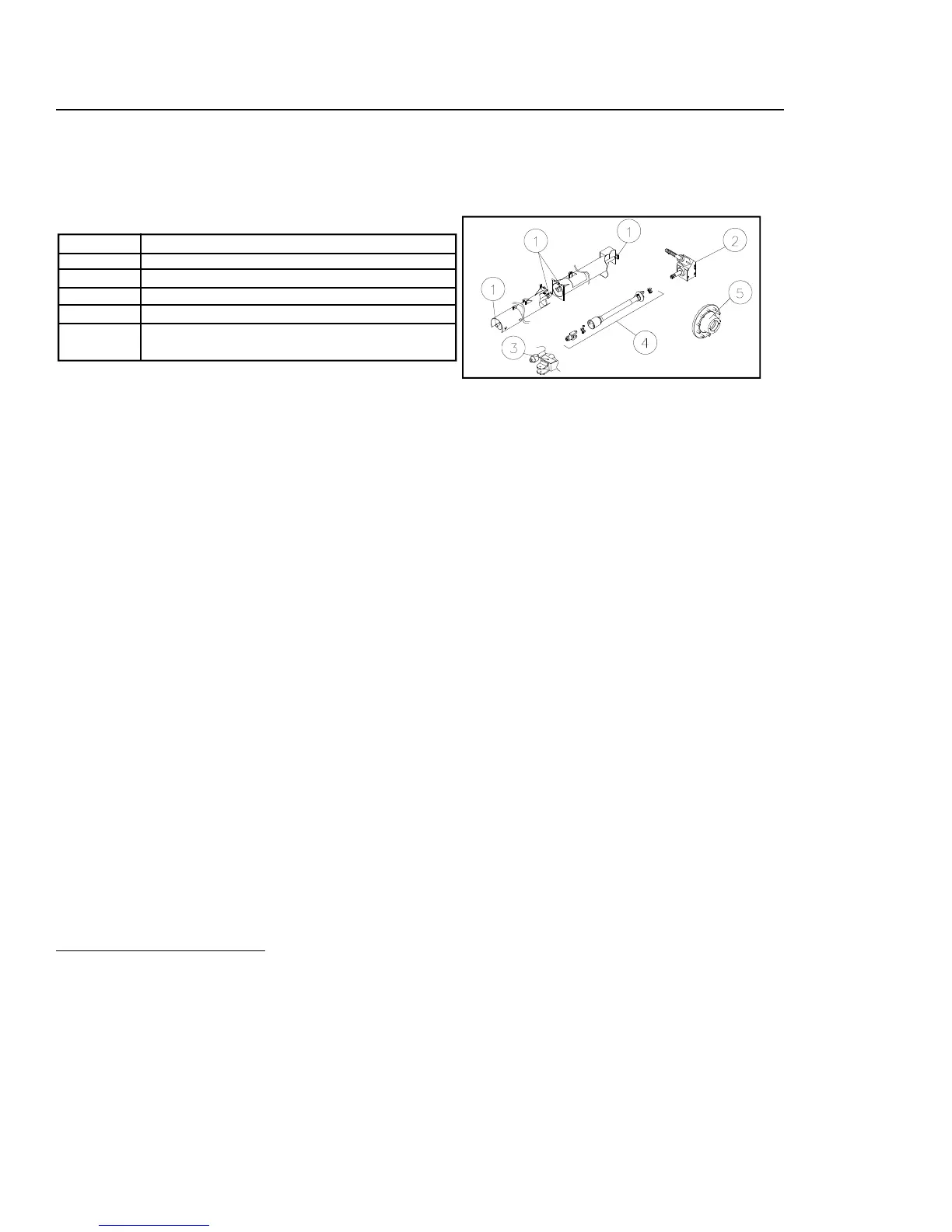

ITEM

1

2

3

4

5

DESCRIPTION

Top, Center, Bottom Bearings - Daily

Replace every season, 2 quarts 90W oil

Five shots of grease per season

See page 10

Repack once every 2 years;

adjust bearing take-up once per season

OM02524

SERVICE TIPS

SELECTING PROPER TRACTOR FOR YOUR CART

Approximate loaded weight of cart -690 -> 41,500 Lbs.

-590 -> 35,000 Lbs.

Approximate loaded hitch weight of cart -690 -> 3,900 Lbs.

-590 -> 3,700 Lbs.

WHEEL NUTS

Check all wheel nuts for tightness before first load. Failure to do so may damage wheel nut seats.

Once seats are damaged, it will become impossible to keep nuts tight. Tighten nuts to 400 ft.Lbs.

Retighten after first three loads and check periodically during first season of use.

TIRE PRESSURE

The following is to be used a general guide for tire inflation. Figures may vary depending on specific

brand of tire used. It is important that tires are inspected after unit is loaded. The tire should stand

up with no sidewall buckling as tire rolls.

18.4 x 38 37 P.S.I.

20.8 x 38 37 P.S.I.

24.5 x 32 38 P.S.I.

30.5 x 32 33 P.S.I.

23.1 x 26 35 P.S.I.

U-JOINTS

The U-joint will give you many years of service if grease is applied to each joint and spline weekly.

GEAR BOX

-- To check fluid level, grain cart must be sitting level.

-- The fluid level plug and fill plug is on the tip side of the gear box.

For maximum gear box life:

-- Check oil level every two weeks

-- Replace oil every season, fill to fluid level or 2 quarts 90 weight oil

Loading...

Loading...