86

9 Engine preservation

Preservatives and Preservation procedure is recommended for engine when it is to be kept idle (out of use)

for prolonged period (more than 12 months).

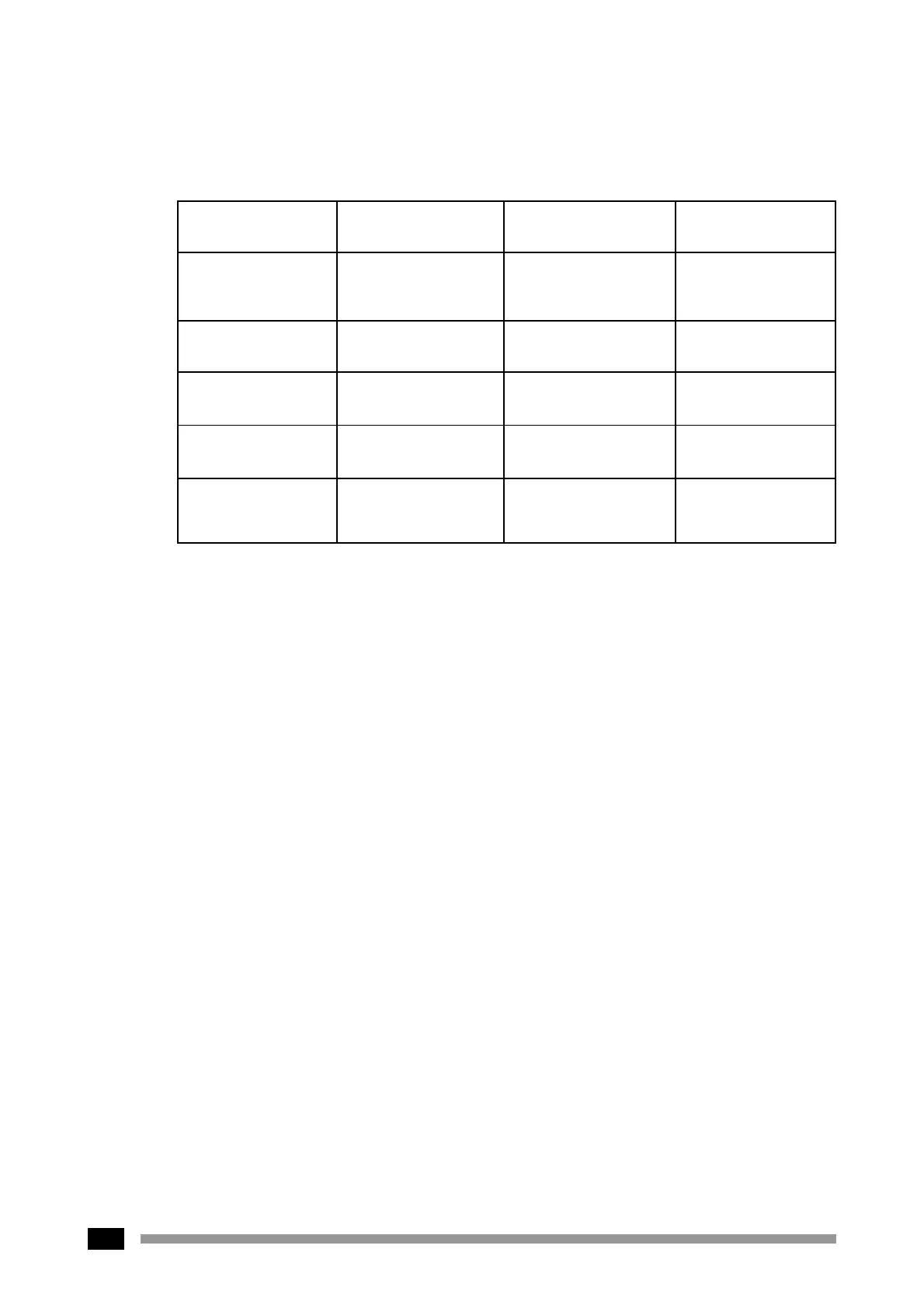

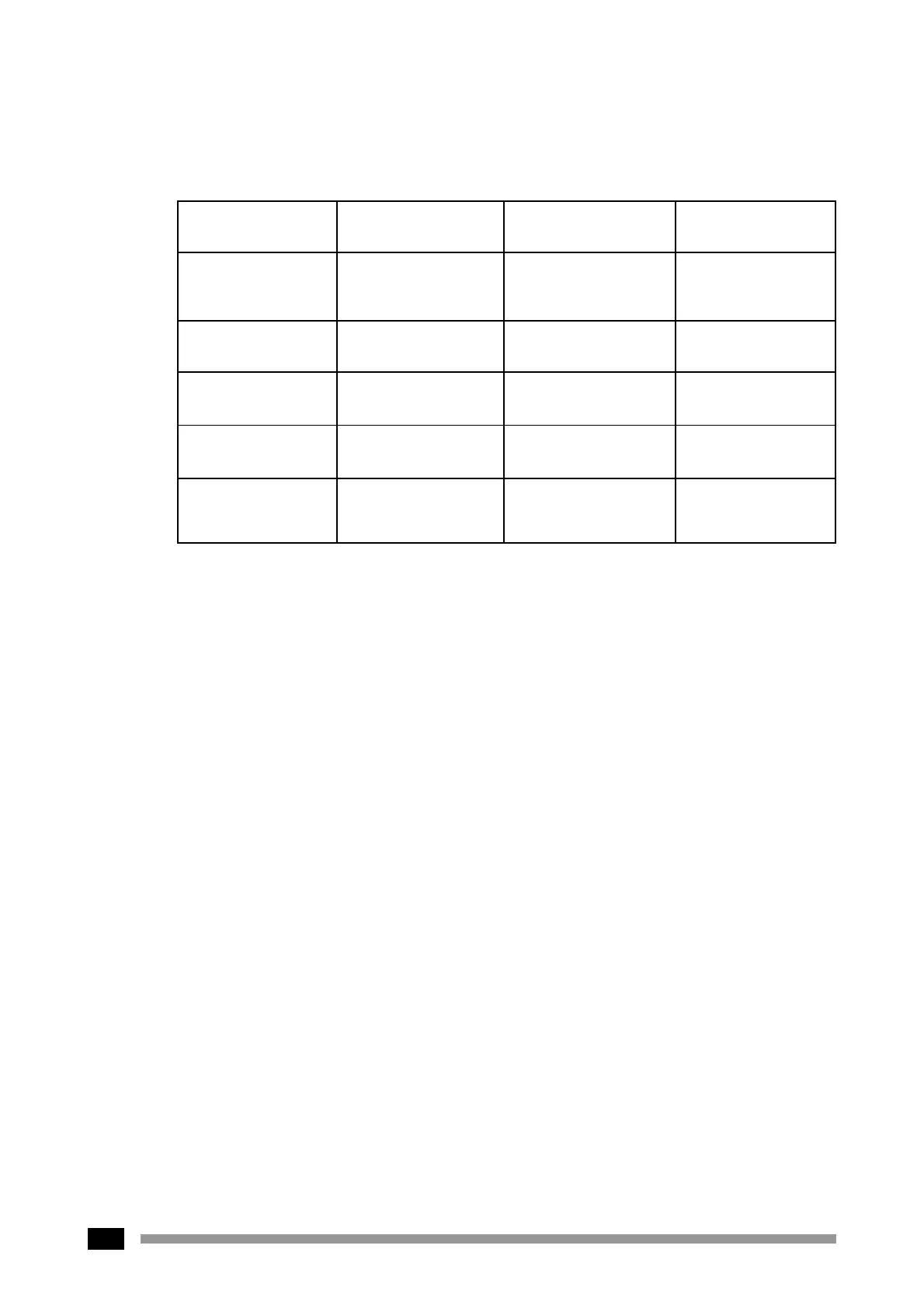

9.1 Recommended Preservatives

MANUFACTURER Engine Lube oil and Engine Cooling Unpainted Ferrous

Fuel system System metal Parts

Bharat Bharat Preserve Bharat Sherol B Bharat Rustrol

Petroleum Oil 30 Emulsion with 152

water in ratio 1:20

Indian Oil Servo Servo Cut S 20% Servo RP 125

Preserve 30 Emulsion with water

Hindustan Autoprun T 120 Koolkit 40 Rustop 274

Petroleum 5% Emulsion with water

Castrol India - - Rustilo DW 904

or DW 901

Tide Water Oil Co. Veedol 30/40 Veedol Amulkut 4 Veedol Ruspro IT

Emulsion with water

in Ratio 1:15

9.2 Preservation Procedure

a) Using H.S.D. fuel, run the engine at approximately 70% of maximum rated speed with ‘No’ load for 5

minutes to warm up the engine (in case of fixed speed engines like engine for Genset, it can be run

at rated speed).

b) After stopping the engine, drain lube oil from sump and refill with suitable preservative oil as mentioned

above.

c) Run the engine on ‘No’ load for 3 minutes. During this time the preservative will be circulated throughout

the lube oil system of engine. Stop the engine and disconnect diesel fuel supply to fuel pump inlet.

For engine speed refer point 8.2 (a).

d) Prepare a solution Diesel + Preservative Oil (5:1 ratio) in a separate tank and connect fuel line from

this tank, directly to fuel pump inlet ensuring gravity feed (by-pass fuel filter).

e) Drain coolant from cooling system and thoroughly flush with clean water. The system then should be

filled with mixture of water and any of the cooling system preservatives mentioned in Annexure-1.

f) Electrically crank the engine tilt it fires ( in case of purely hand start engine, hand - crank the engine

using decompressor lever, till it fires) and let it run for 30 seconds. During this time the diesel in fuel

pump gallery and high pressure pipes will be displaced by Diesel + Preservative Oil mixture. Stop the

engine.

Engine speed during above running -

• In case of variable speed engine - 800 to 1000 rpm

• In case of fixed speed engine - Rated speed at ‘No’ load. (Genset, Pumpset etc.)

g) Close the air inlet manifold (for the air cleaner inlet) and crank the engine by starter for 5 to 10

seconds. (In case of purely hand start engine, it should be hand cranked using the de-compressor

lever). This will ensure coating of Diesel + Preservative oil on the combustion chamber surfaces.

h) Drain preservative oil from oil sump, reinstall drain plugs and reconnect fuel filter into the fuel pipe

line.

i) Treat all unpainted external ferrous metal parts with two coats of suitable rust preventer as recommended

in 8.1, allowing sufficient time for the first coat to thoroughly dry before applying second coat.

Loading...

Loading...