Do you have a question about the KIRLOSKAR UP 200/30 and is the answer not in the manual?

Identifies pumps by serial number, model, size, and type stamped on an identification plate.

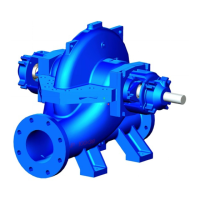

Details the construction of casing, impeller, shaft, shaft sleeves, inserts, and bearings.

Explains the naming convention for pump types, e.g., UP 100/35.

Covers essential safety precautions for installation, operation, and maintenance personnel.

Provides guidelines for safe handling, lifting, and storage of pumps to prevent hazards.

Instructions for inspecting the pump upon receipt and preparing it for installation.

Guidance on selecting the pump location and constructing a suitable foundation.

Procedures for setting the baseplate and applying grout.

Steps for alignment and factors that can disturb it.

Best practices for installing suction and discharge piping to ensure efficient pump operation.

Checklist of inspections required before initial pump startup.

Step-by-step guide for safely starting, operating, and stopping the pump.

Details pump types, rotation direction, and bearing models.

Guidelines for bearing maintenance, lubrication, and mechanical seal handling.

Information on wear rings, impeller types, and stuffing box configurations.

Information on mechanical seal fitting and general care.

Data on couplings, minimum flow rates, NPSHA requirements, and pipe velocities.

Technical data including allowable flange forces, pipe sizes, speed limits, torque, and weights.

Chart detailing interchangeable components across different pump models.

Environmental, Health, and Safety guidelines for maintenance tasks.

A chart outlining weekly, monthly, and yearly maintenance checks.

Step-by-step instructions for safely disassembling the pump.

Detailed steps for correctly reassembling the pump after overhaul.

Specifies torques and sequence for tightening main joint flange studs and nuts.

Instructions for cutting, fitting, and adjusting stuffing box packing rings.

Lists all part codes and their descriptions for easy identification and ordering.

Lists components specific to soft packed and mechanical seal pump configurations.

Overarching safety guidelines for product use, handling, and electrical safety.

Specific safety instructions for pump assembly, commissioning, and operational phases.

Guidelines for safe practices during pump maintenance, repair, and component handling.

Identifies pumps by serial number, model, size, and type stamped on an identification plate.

Details the construction of casing, impeller, shaft, shaft sleeves, inserts, and bearings.

Explains the naming convention for pump types, e.g., UP 100/35.

Covers essential safety precautions for installation, operation, and maintenance personnel.

Provides guidelines for safe handling, lifting, and storage of pumps to prevent hazards.

Instructions for inspecting the pump upon receipt and preparing it for installation.

Guidance on selecting the pump location and constructing a suitable foundation.

Procedures for setting the baseplate and applying grout.

Steps for alignment and factors that can disturb it.

Best practices for installing suction and discharge piping to ensure efficient pump operation.

Checklist of inspections required before initial pump startup.

Step-by-step guide for safely starting, operating, and stopping the pump.

Details pump types, rotation direction, and bearing models.

Guidelines for bearing maintenance, lubrication, and mechanical seal handling.

Information on wear rings, impeller types, and stuffing box configurations.

Information on mechanical seal fitting and general care.

Data on couplings, minimum flow rates, NPSHA requirements, and pipe velocities.

Technical data including allowable flange forces, pipe sizes, speed limits, torque, and weights.

Chart detailing interchangeable components across different pump models.

Environmental, Health, and Safety guidelines for maintenance tasks.

A chart outlining weekly, monthly, and yearly maintenance checks.

Step-by-step instructions for safely disassembling the pump.

Detailed steps for correctly reassembling the pump after overhaul.

Specifies torques and sequence for tightening main joint flange studs and nuts.

Instructions for cutting, fitting, and adjusting stuffing box packing rings.

Lists all part codes and their descriptions for easy identification and ordering.

Lists components specific to soft packed and mechanical seal pump configurations.

Overarching safety guidelines for product use, handling, and electrical safety.

Specific safety instructions for pump assembly, commissioning, and operational phases.

Guidelines for safe practices during pump maintenance, repair, and component handling.

| Brand | KIRLOSKAR |

|---|---|

| Model | UP 200/30 |

| Category | Power Pump |

| Language | English |