6-14

n

KitchenAid 2015 Microltration Dishwashers

TESTING

For Service Technician Use Only

DANGER

Electrical Shock Hazard

Only authorized technicians should perform

diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can result in

death or electrical shock.

Wash Motor

This test will check the wiring to the wash motor and the wash

motor itself. The following items are part of the wash motor

circuit.

n Harness/Connecon

n Wash Motor & Capacitor

n Control Board

Test Procedure

1. Check the tub and sump for anything that may be

impeding water ow. Inspect and if necessary clean the

coarse-lter system. Also, inspect spray arm water nozzles

and clean if needed.

2. Check the wash motor and electrical connecons by

performing the Service Diagnosc Cycle. The following

steps assume that this step was unsuccessful.

3. Unplug dishwasher or disconnect power.

4. Remove toe and access panels to access control board.

5. Unplug connector P5 from control board.

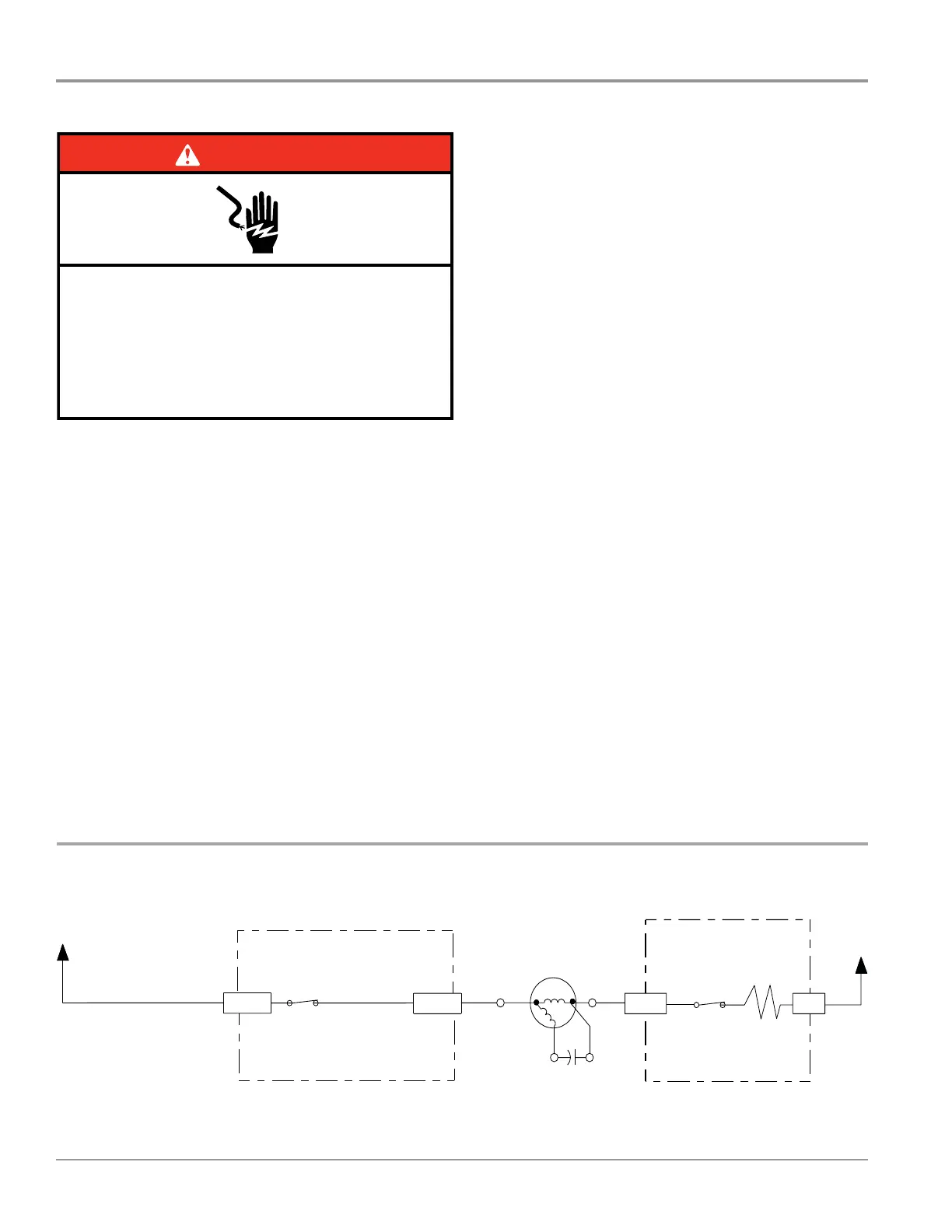

Strip Circuit – Wash Motor

6. Check the wash motor—using an ohmmeter, measure the

resistance between P5-1 and P5-2.

¾ If the resistance is between 10-15 ohms, the wash

motor and harness are good. Go to step 7.

¾ If outside the range, replace the wash motor.

¾ If an open circuit is detected, check connecons and

harness connuity between control and wash motor. If

good, replace the wash motor.

7. Reconnect P5 to control board.

8. Set voltmeter to AC and connect leads to test-pads

P5-1 & P5-2 on the control board. Plug in dishwasher or

reconnect power.

9. Start the Diagnosc Cycle and at the proper interval

measure for AC out of the control between P5-1 & P5-2.

(Refer to Wash Motor Strip Circuit below.)

¾ If no AC voltage is measured, replace the control board

and retest.

¾ If 120 VAC is measured and wash motor is running, go

to step 12.

¾ If 120 VAC is measured and wash motor is not running,

go to step 10.

10. Test the wash motor capacitor. NOTE: A faulty capacitor

may cause the motor to “hum,” not start, or start slowly.

a. Discharge the capacitor by touching the leads of a

20,000 Ω resistor to the two terminals.

b. Disconnect the wires from the capacitor terminals.

c. With an ohmmeter, measure across the terminals and

note reading.

¾ If a steady increase in resistance is noted, capacitor is

good. Replace wash motor assembly and retest.

¾ If the capacitor is either shorted or open, replace

capacitor. and retest.

11. If the preceding steps did not correct the wash motor

problem, replace the control board.

12. Unplug dishwasher or disconnect power.

13. Reassemble all parts and panels.

14. Plug in dishwasher or reconnect power and run Diagnosc

Cycle to verify repair.

4

Control Pinout

Meter Check of Loads and Fuses

Dishwasher Strip Circuits

The following individual circuits are for use in diagnoses. Do not continue with

the diagnosis of the appliance if a fuse is blown, a circuit breaker is tripped, or if

there is less than a 120-volt power supply at the wall outlet.

■ Unplug dishwasher or disconnect power.

■

Perform resistance checks. To check resistance of a component,

disconnect harness leads first.

Door Switch

Wash/Rinse

Water Heating/Heat Dry and Water Sensing with O.W.I. Sensor (Water/Air/Soil/Temperature)

Pump is washing. Control monitors temperature during water heating periods. See “Wash/Rinse” and “Water Sensing with O.W.I. Sensor (Water/Air/Soil/

Temperature)” circuits.

Fill

(Top)

W2

P5

P6

P7

P8 P9

P10 P11

P12

P13

-4

-3

-2

-1

-2

-1

-1

-6

-9

-1

-6

-1

-6

-1

-5

-6

-1

-3

-5

-1

-2

-4

-6

-1

-3

(OWI)

P12 (Wide Out)

P13

P4

P5

P6

BR

P7

BU

P8

RD

P9

V

P10

BR

P11

RD

P12

YL

Ω of F9 Triac Fuse

Electronic Control

Electronic Control

Micro PinMicro Pin

Micro PinMicro Pin

K4

Motor (N) Relay

K3

Heater (L1) Relay

K2

Pilot (L1) Relay

K1

Heater (N) Relay

N.O. N.O. N.O. N.O.

(To Wash Motor)

(To Heater)

(To Wash Motor,

Vent, and Triac Loads)

(To Heater)

N.O.

Door

Switch

Sensing

Input

Ref

P9-5

P10-4

Door

Switch

P9-6

13V

VV

Motor Power

BK

N.O.

TURQ

(LBU)

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Electronic Control

P4-2

P5-2

Pin 3

Pin 2

K4

Motor N Relay

(Also see Door

Switch Circuit)

WH

P5-1

P4-1

Sense Resistor

or Jumper

0

Ω

N

L1

V

Y

Y

AUX

Winding

6

Ω

- 10

Ω

CAP

23.5 µF

Run

Winding

3

Ω

- 7

Ω

Motor and Capacitor

(Wash Pump)

120V, 60 Hz, 190W typical

TURQ

(LBU)

Electronic Control

N.O.

L1

BK

Electronic Control

N.O.

K3

Heater L1 Relay

(Also see Door

Switch Circuit)

Hi-Limit

Thermostat

Opens

207°F - 217°F

(97°C - 103°C)

Heater Element

8

Ω

- 30

Ω

120V, 60 Hz

785W Wet

500W Dry

N.C.

P4-2

P4-3

P4-4

P4-1

N

Electronic Control

N.O.

K1

Heater N Relay

(Also see Door

Switch Circuit)

Electronic

Control

P12-6

P12-5

P12-4

P12-3

P12-2

P12-1

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Measure NTC resistance at P12-1 and

P12-3 connector disconnected from control.

Turbidity Drive

Foam Drive

OPT Sig

VCC

Ref

NTC

O.W.I. Sensor

Temperature: NTC Thermistor

46K

Ω

- 52K

Ω

at 77°F (25°C)

11K

Ω

- 13K

Ω

at 140°F (60°C)

Heater

BU/RD BU/RD

BU/WH

WH

YL

YL

YL

YL

YL

YL

L1

BK

P4-2 P6-4

P10-1

P6-6

P6-7

P6-9

P4-1

Use top hole of jumper

W2 as test point for F9.

N.O.

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Fuse

F9

Electronic Control

Electronic Control

Float

(In normal position,

holds switch closed.)

BR

BR

N.O.

Pin 3 Pin 1

Overfill

Float Switch

No test pad on P6-4.

Recommend using test pad on P10-1.

No test pad on P6-7.

Recommend using test pad on P6-6.

Electronic Control

Float Switch

Input

BR

BR

Pin 3 Pin 1

Triac

Fill Valve

890

Ω

- 1,090

Ω

120V, 60 Hz, 6W

WH

N

Loading...

Loading...