— 20 —

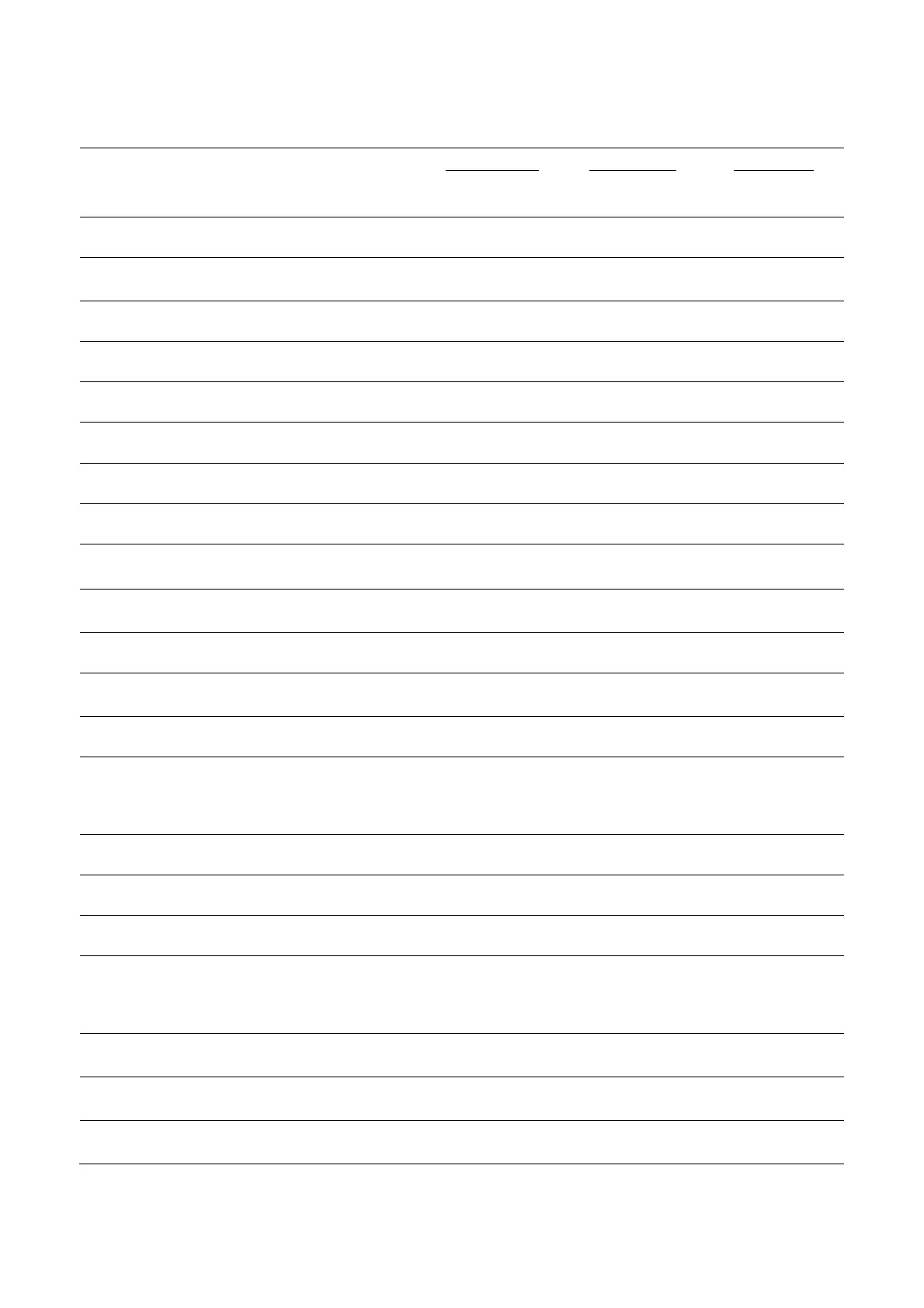

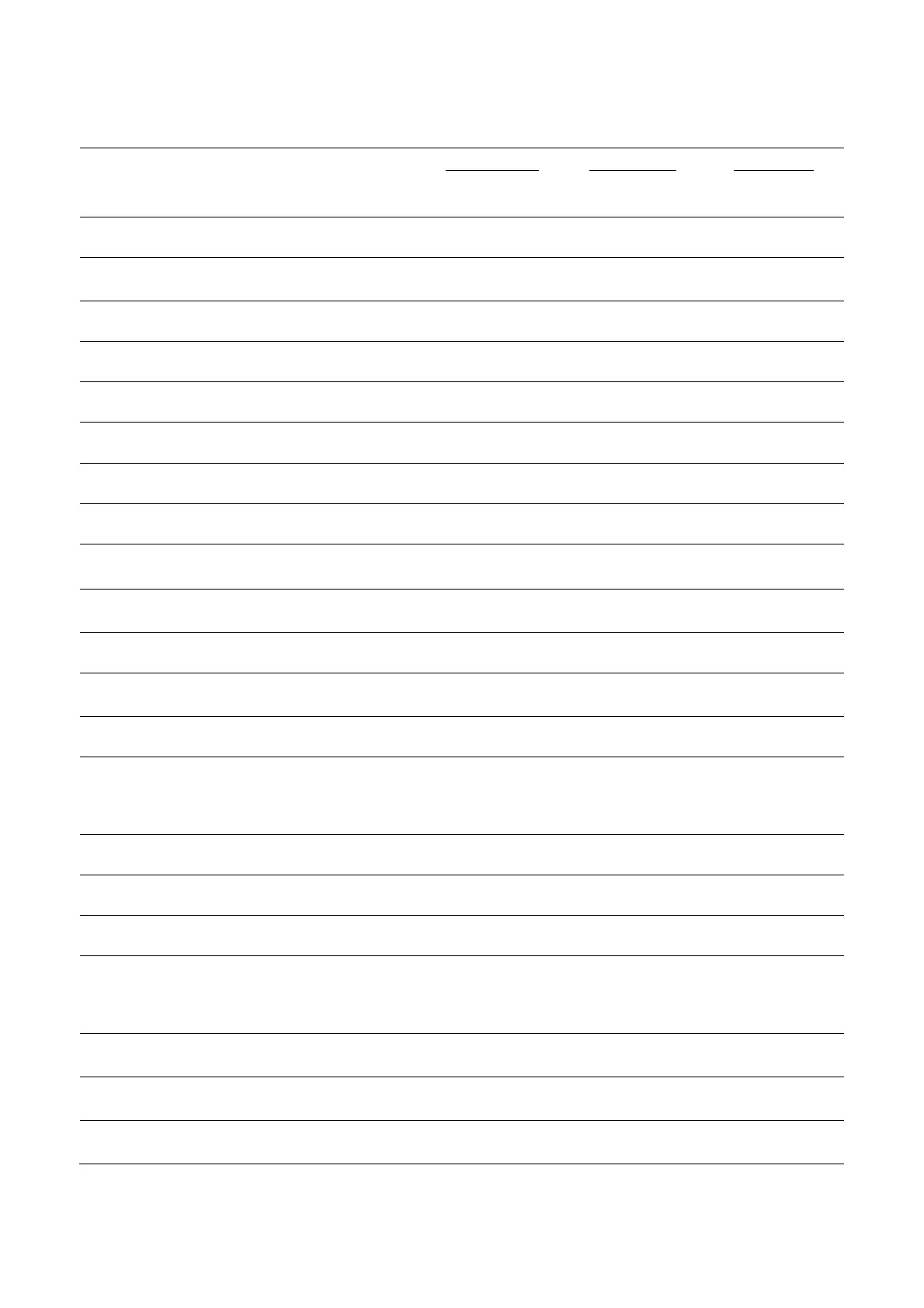

TABLE INSPECTION FOR ELECTRC CHAIN HOISTS

Item

Normal Service

Heavy Service Strict Service

Visual

Monthly

Record

Yearly

Visual

Weekly

Record

Semiannually

Visual

Daily

Record

Quarterly

FREQUENT inspection (see 5-2)

All functional operating mechanisms for

maladjustment and unusual sounds

*

-

*

-

*

-

Brake slippage (see 5-2.a.) *

-

*

-

*

-

Optimal control functions (see 5-2.b.) *

-

*

-

*

-

Hook damage, crack, bend and opening (see 5.2.c.) *

-

*

-

*

-

Hook latch operation (see 5-2.d.) *

-

*

-

*

-

Optimal load chain lubrication (see 5.2.e.) *

-

*

-

*

-

Load chain in accordance with 5-2.e. *

-

*

-

*

-

Load chain reeving for compliance with hoist

manufacturer

’s recommendations

*

-

*

-

*

-

Load sheave engagement with load chain: load chain

twisting.

*

-

*

-

*

-

Idle sheave engagement with load chain: load chain twisting.

*

-

*

-

*

-

Proper limit switch actuation and motor stopping when the

hook rises at upper limit under no load.

*

-

*

-

*

-

No deformed, peeled and cracked cushion rubber.

*

-

*

-

*

-

No damaged chain spring (option), and minimum free length

75mm (130mm), of the chain spring.

Note: Initial free length of the spring 85mm (150mm).

* ( ): 60-240kg

*

-

*

-

*

-

PERIODIC inspection (see 5-3)

Requirements of frequent inspection

-

*

-

*

-

*

Evidence of loose bolts, nuts or rivets (see 5-3.b.)

-

*

-

*

-

*

Evidence of worn, corroded, cracked, or distorted

parts such as load blocks, suspension housing, chain,

attachments, clevises, yokes, suspension bolts, shafts,

gears, bearings and pins. (see 5-3.c.)

-

*

-

*

-

*

Imperfect insulation of cables, cord and control station

(see 5.3.h.)

-

*

-

*

-

*

Evidence of damage or excessive wear of sheave

(see 5-3.e.)

-

*

-

*

-

*

Evidence of excessive wear on friction clutch

(see 5-3.f. 6-3)

-

*

-

*

-

*

Loading...

Loading...