— 33 —

Trouble Condition Cause Solution

Brake

slippage.

* Braking distance is too long,

even under no-load conditions.

* Motor has become

demagnetized, owing to

too frequent use.

* Replace with a normal

one.

* improper contact of

electromagnetic

contactors.

* Deteriorated resistor for

dynamic braking.

* The load cannot be held at the

level when stopping operation.

* Improper gear oil use. * Replace the specified gear

oil.

* Within rated load, lifting/

lowering speed is slow.

* Deterioration of clutch

brake.

* Replace the set of

mechanical brake with

friction clutch.

Oil leakage.

* Oil leakage from case joint and

chain guide.

* Defective gear case

packing/oil seal.

* Replace with a normal

one.

* Loosened assembly bolts. * Fasten with normal

torque.

* Leakage from oil plug. * Loosened oil plug. * Fasten oil plug.

A clicking

sound is

heard from

the load chain

during lifting.

----------

* Wear of load sheave. * Replace with a normal

one.

* Wear of load chain.

* Rust on load chain.

Electric

shock.

----------

* Accumulation of

moisture/foreign matter

on electrical instruments.

* Remove moisture/foreign

substance.

* Improper grounding. * Secure correct grounding.

Ask your local Kito dealer to repair.

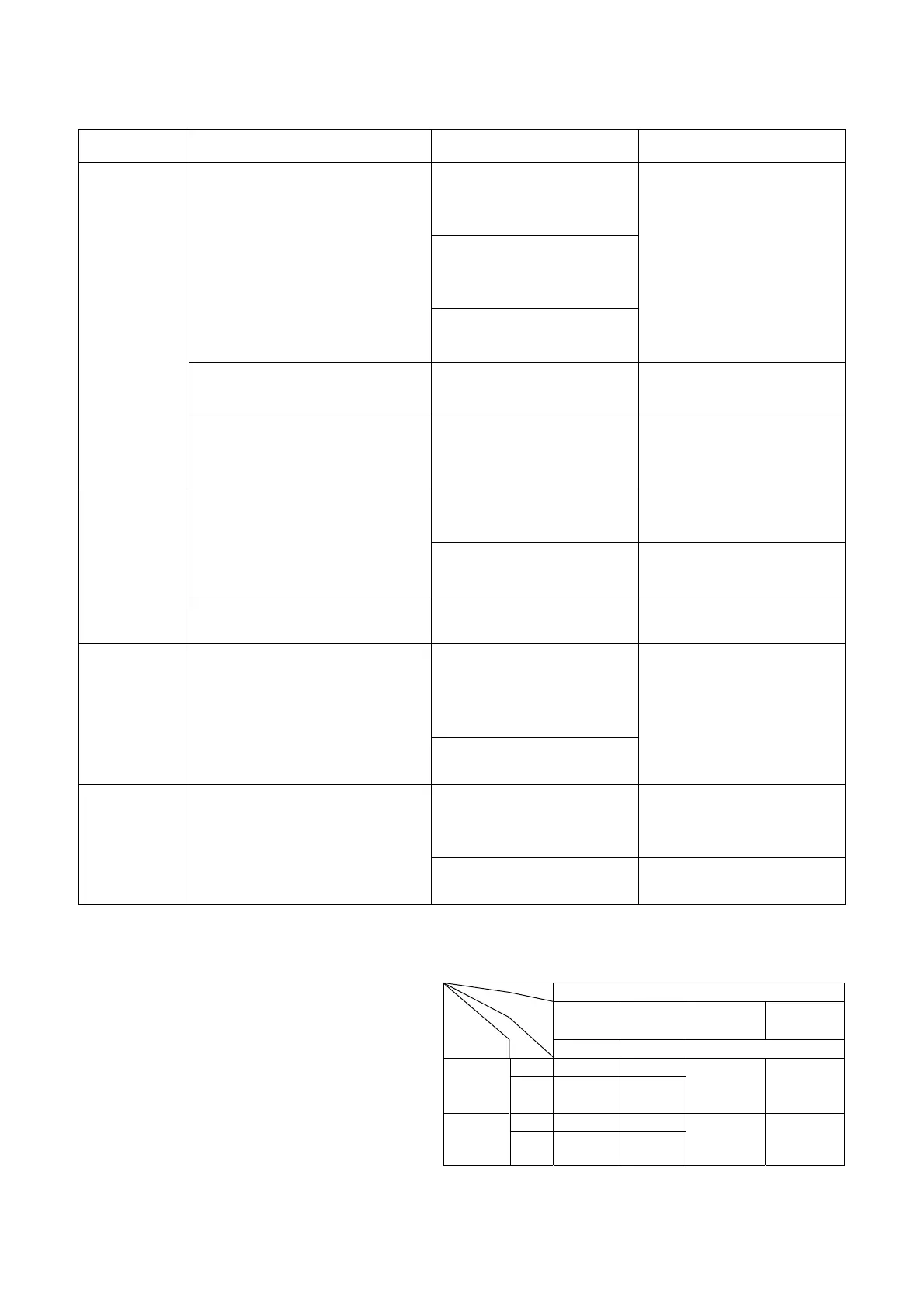

For maintenance, a fuse shown in the table is

attached in the controller cover (the capacity/

name plate side) as a spare.

Fuses for maintenance

Rated

power

source

Fuse capacity [A]×(Nos. per hoist) [pcs.]

Rated road

[kg]

120 [V] 240 [V] 120 [V] 240 [V]

Speed Normal voltage operation Low-voltage operation

60

80

180

Single 10×(2) 5×(2)

10×(2) 5×(2)

Dual

10×(2)

0.1×(1)

5×(2)

0.1×(1)

160

240

480

Single 15×(2) 10×(2)

15×(2) 10×(2)

Dual

15×(2)

0.1×(1)

10×(2)

0.1×(1)

Loading...

Loading...