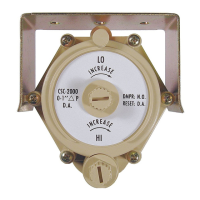

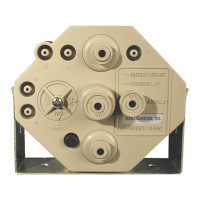

CSC-3000 Series Pneumatic VAV Reset Volume Controllers 7 Applications Guide, Rev G

Troubleshooting

NOTE: The controller should be set according

to the specications found on the

manufacturer’s label on the VAV box.

NOTE: The CSC-3000 series are position sensitive.

Be sure to mount the controller with

the correct orientation. See Mounting on

page 2. If the controller is calibrated in a

position other than the nal mounting

position, the calibration (minimum and

maximum ow limits) will be o.

NOTE: Thesecontrollersaretypicallyusedon

single-ductapplicationsbutmaybe

foundindual-ductapplications.(See,for

example,Dual Duct on page 13andDual

Duct, Constant Volume on page 14

.)When

workingondual-ductapplicationsitmay

benecessarytoworkononeductatatime.

Troubleshootingissuestoconsiderinclude:

• Isthereanadequatemainair(M)supply?

• Isthereadequateupstreamsystem(duct)air?

• Istheapplicationcorrectandpipedcorrectly?

SeeConnections on page 3,Determining the Type

of Reset on page 4

,andApplications on page 10.

•

Isthedamperaction(NC/NO)setcorrectly?Do

thedamper’sandcontroller’sactionmatch?See

Damper Action on page 4.

•

Isthedamperbinding?Willtheactuatordrive

thedamperfullopentofullclose?(Sucient

mainairisrequiredtoprovidetheactuatorwith

enoughforcetooperatethedamper/linkage.)Is

theactuatorleaking?(Evensmallleakscancause

theactuatortonotstroke.Youcantestforleaks

withasqueezebulbtoensuretherearenoleaks

attheactuatordiaphragmorings.)

• Doesthethermostatsendanadequatesignalto

thecontroller?

• AreLOSTATandHISTATsetcorrectlyforthe

thermostataction?Whencycled,canthecontrol-

lerrepeattheLOSTATandHISTATseings?If

theLOSTATorHISTATmustbesetfor“0”wc,

seethenotesaboutzero minimuminDIRECT

Reset Minimum and Maximum on page 4

orRE-

VERSE Reset Minimum and Maximum on page 5.

Maintenance

Noroutinemaintenanceisrequired.Eachcompo-

nentisdesignedandmanufacturedforreliability

andperformance.Carefulinstallationandusewill

ensurelong-termdependability.

CAUTION

Pneumatic devices must be supplied with clean,

dry control air. Any other medium (e.g., oil

or moisture contamination) will result in the

device’s eventual failure.

• Istheairowpickupproperlyplaced,anddoesit

sendagooddierentialpressuretothecontrol-

ler?(SeeConnections on page 3.)Istheairow

sensordirtyordefective?(Disconnectthesensor

fromthecontrollerbeforeaemptingtoblowthe

sensorclean!)

• Areresetstartandresetspansetcorrectly?See

Reset Start Point on page 6andReset Span on

page 6.

Important Notices

TheKMClogoisaregisteredtrademarkofKMC

Controls,Inc.Allrightsreserved.Nopartofthis

publicationmaybereproduced,transmied,tran-

scribed,storedinaretrievalsystem,ortranslated

intoanylanguageinanyformbyanymeanswith-

outthewrienpermissionofKMCControls,Inc.

Thematerialinthisdocumentisforinformation

purposesonly.The contents and the product it de-

scribes are subject to change without notice.KMC

Controls,Inc.makesnorepresentationsorwarran-

tieswithrespecttothisdocument.Innoeventshall

KMCControls,Inc.beliableforanydamages,direct

orincidental,arisingoutoforrelatedtotheuseof

thisdocument.

Loading...

Loading...